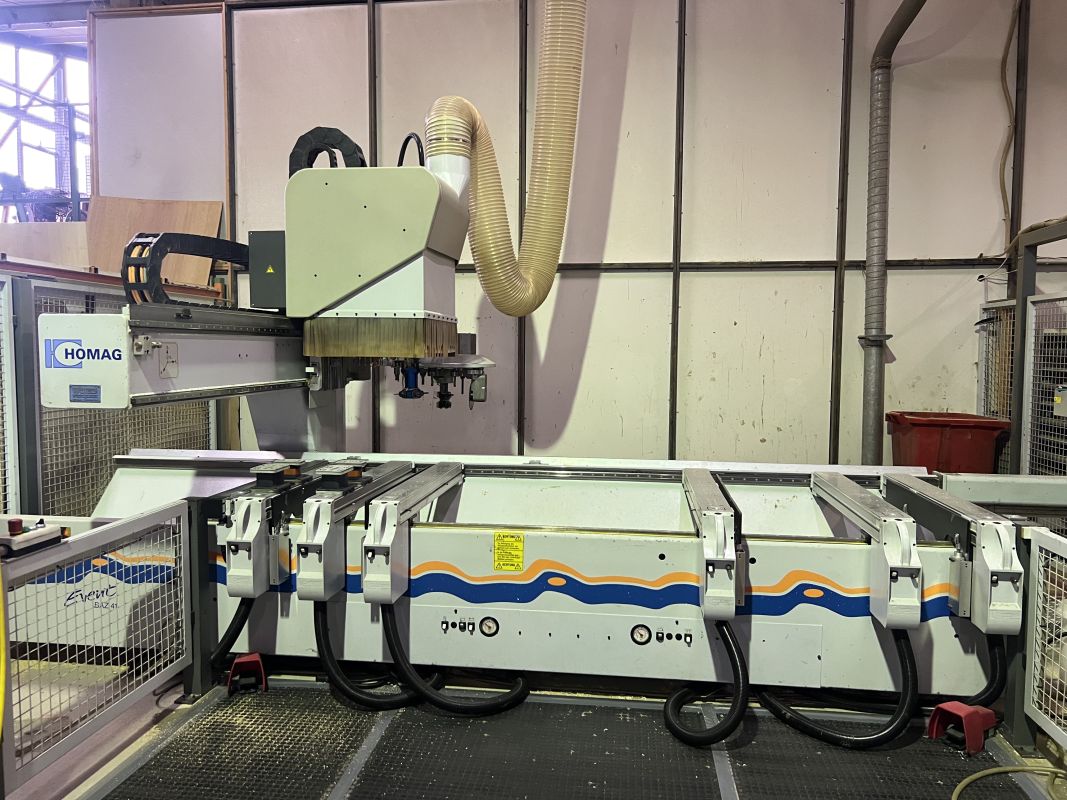

BrandHOMAG

typeOptimat BAZ41/30/K Event

stateUsed

stock number0401924

year2003

Workpiece length max. 3000 mm

Workpiece width: max. 1300 mm

Workpiece thickness: max. 60 mm

Main spindle 7.5 kW HSK F63

Questions about this machine

CNC machining center

Brand: Homag

Type: Optimat BAZ41/30/K Event

Year of manufacture: 2003

Technical data

- Workpiece length max. 3000 mm

- Workpiece width: max. 1300 mm for milling with a tool diameter of 25 mm, max. 1150 mm for all units

- Workpieces larger than 1150 mm must be placed against the rear longitudinal stops

- Workpiece thickness: max. 60 mm with standard clamp, max. 200 mm with clamping templates

4 lifting rails

- With plastic sliding coating, attached to the sides of consoles 1, 3, 4, 6

- Lifting device for 100 mm clearance under the workpiece support

- Total stroke approx. 105 mm

- Lifting force per lifting rail 25 kg

- The min. part size increases by 50 mm

Pendulum machining

- For milling/drilling (no gluing) of 2 workpieces in pendulum mode

- Separate workpiece clamping with separate foot switches

- Workpiece length in pendulum mode max. 900 mm

Main spindle 7.5 kW water-cooled

- For HSK F63

- Vector-controlled asynchronous motor 7.5 kW at S1

- Tool weight max. 5 kg incl. holder

- Tool length max. 200 mm from lower edge of motor spindle

- Tool diameter: max. 180 mm for milling tools, max. 200 mm for grinding tools

- Speed range continuously programmable from 0 - 18000 rpm

- Full rated power from 12000 rpm

12-station turret changer

- for tools and units with HSK F63

Possible tool and unit configurations:

- 12 x max. diameter 130 mm or

- 6 x max. diameter 180 mm and 6 x max. diameter 70 mm

Laser positioning aid for vacuum clamps

Drilling head 17 spindles vertical

- 1 motor 4 kW, frequency-controlled

- Speed: 4500 - 6000 rpm selectable via program

- For vertical drilling, extension stroke 50 mm

- 17 drilling spindles up to max. 35 mm bore diameter

- Each spindle individually selectable

- 11 spindles in X direction, 7 spindles in Y direction

- Spindles arranged in T-shape

- Spindle spacing 32 mm

- Total drill length 70 mm

- Shank diameter 10 x 20 mm

- With clamping surface and adjusting screw

- Direction of rotation: alternating left-right rotation

Aggregate interface

- For connecting the machining aggregates

- Including pneumatic interface and swivel drive C-axis with torque transmission and 3-point support

- Drive for all aggregates with swivel axis

- Swivel range without limitation

- Tubeless compressed air supply

Sawing and trimming unit

- for automatic replacement in the main spindle

- for grooves and cuts from above at any angle to the workpiece, as well as right-angled notches

- trimming of edge overhangs and cutting to a maximum workpiece thickness of 50 mm

- speed max. 9000 rpm

- Mounting flange diameter 30 mm with 4 countersunk head screws M5. TK diameter 52 mm. LL

- Includes cutting and crosscut saw diameter 180x30x3.2 Z=54

- Saw blade thickness max. 10 mm for grooving

- Saw blade diameter max. 200 mm

- Unlimited swiveling via C-axis

Adapter drill head horizontal 4-SP+saw 0/90 degrees

- Pneumatic swiveling 0/90 degrees

- Drive via drill head

- For horizontal drilling in 4 directions (X+/X-/Y+/Y-)

- One drill spindle prepared for groove saw blade for grooving in X and Y direction

- Extension stroke 100 mm in Z direction

- Drill chuck diameter 10 mm

- Drill length 70 mm

- Drill diameter max. 10 mm

- With clamping surface and adjusting screw

- Saw blade diameter 125 mm

- Saw blade width max. 6 mm

- Mounting flange diameter 30 mm

- 4 countersunk head screws M 5

- Pitch circle diameter 48 mm

- Speed max. 8000 l/min

Blow-off nozzle Workpiece edge for tool changer

Gluing unit 360 degrees

- For straight edges with direct glue application

- Edge feeding by hand as strip material

- Inner radius min. R=30 mm at 90-degree corner

- Outer radius depending on flexibility of edge material

- Edge height max. 65 mm

Edge thickness

- Plastic: 0.4 - 3 mm

- Veneer: 0.4 - 2 mm

- Workpiece width: 1220 mm

Combined flush milling and finishing unit

- Side 1 designed for flush milling

- Side 2 for finishing the pre-milled edge

- Scanning from above, below, and from the side

- Min. outer radius approx. R=5 mm at 90-degree corner

- Min. inner radius approx. R=30 mm at 90-degree corner

- Speed max. 12000 rpm

- Workpiece thickness max. 60 mm

- Min. workpiece overhang approx. 25 mm

2 x WPL radius cutter head

- Z=3, incl. 9 indexable inserts

- Edge thickness max. radius + 1 mm

- Radius R= 2 mm

2 x profile cutters for finishing

- Radius R= 2 mm

External pre-cutting station and single roller

- Roller diameter 800 mm

- Edge length min. 350 mm

- Edge height max. 65 mm

Ethernet network connection

WoodWop package AV-PC BAZ-arm Optimat

Note:

The technical data and descriptions are copies of the order confirmation at the time. The information is for informational purposes only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia