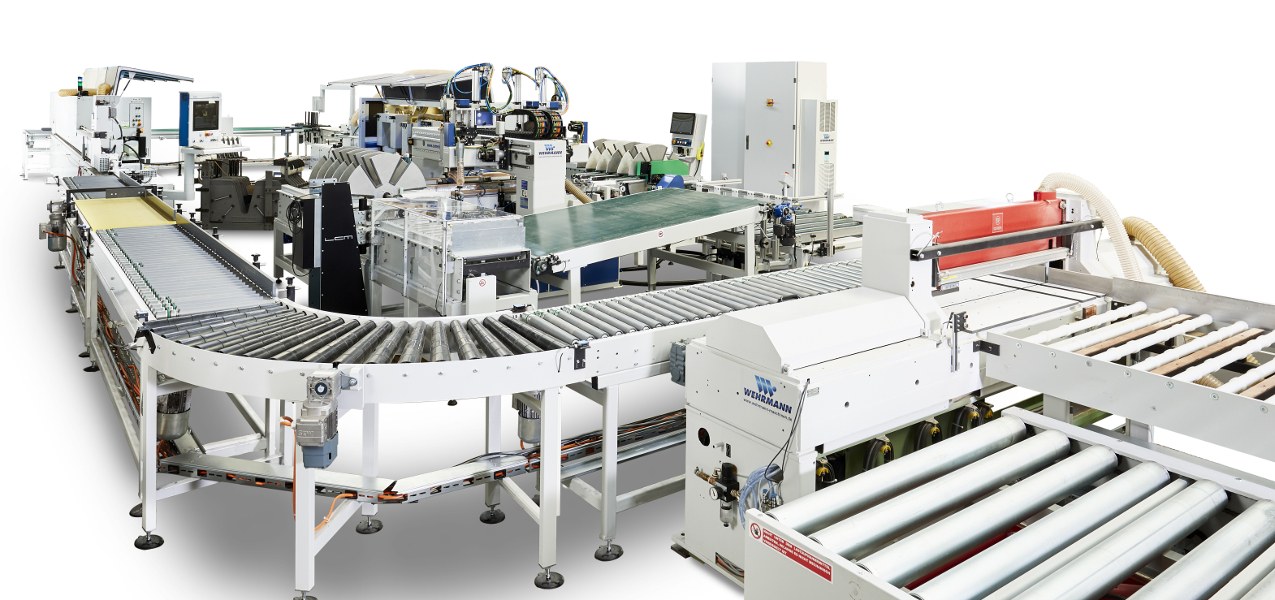

Wehrmann has designed a fully automatic system for the complete processing of drawer front pieces

Four goals:

- Automation due to shortage of skilled workers.

- Complete processing of the parts in one pass to save distances, time and unnecessary steps.

- Take space requirements into account and stay within the existing hall area.

- Create increased capacity for ongoing projects and future growth.

By perfectly arranging the individual machines and transports in just 160m², the entire system can be operated by one person. The enormous performance with an average part dimension of 500mm x 150mm is around 8000 finished drawer parts per shift in just one pass.

System description:

- Strand saw: The drawer front pieces come into the processing line as small stacks of strand goods. In the first step, the individual components from the mother plates are divided into the appropriate widths using a strand saw. The micro-stacks created in this way ensure that a sufficient number of parts are always available before edge processing.

- Separation: The micro stacks are separated using scrapers and speed-regulated conveyor belts.

- One-sided edge processing: This is where the upper visible edge is attached and the bottom groove is milled.

- Double angle transfer: Compact and powerful thanks to the use of two star turners.

- One-sided edge processing: For the blind edge at the bottom.

- Drilling system: Frames and handle holes are added with two processing stations.

- Cleaning brush: Adhering chips from previous processing steps are removed.

- Stack formation: Formation of new micro-stacks with manual remove and simultaneous quality control.

The use of new and used machines as well as transport devices created a balanced mix of costs

and benefits. The required performance of the fully automatic system designed by Wehrmann was not only achieved, but exceeded.

This video will be loaded from Google YouTube.

Their

privacy policy applies.