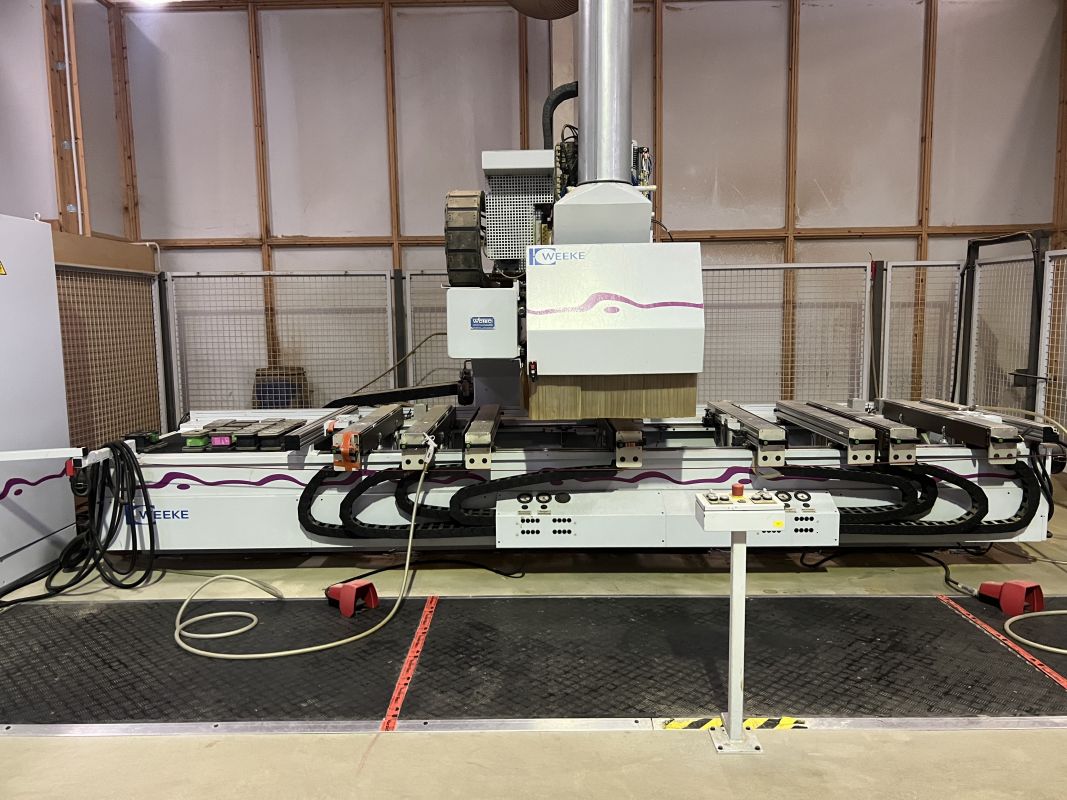

BrandWEEKE

typeOptimat BP 145

stateUsed

stock number0401925

year2000

Working length: 3500 mm

Working width: 1300 mm

tool change spindle 9 kW - HSK F63

Questions about this machine

CNC machining center

Brand: Weeke

Type: Optimat BP 145

Year of manufacture: 2000

Technical data

Working length: 3500 mm

Working width: 1300 mm

1 vertical drilling unit with 22 spindles

Feed stroke Z: 60 mm

Drive: 1.5 kW

Direction of rotation: right/left

Speed: 1500 rpm to 5000 rpm, frequency-controlled

Drill chuck: 10 mm

Drilling depth: max. 38 mm

Total drill length: 70 mm

Drill diameter: max. 20 mm, one spindle up to 25 mm, max. 35 mm

Spindle spacing: 32 mm (21 spindles)

1 horizontal drilling unit with 4 spindles

2 drilling spindles each in a 32 mm grid on the right and left in the X direction

Drilling height in the Z direction: max. 38 mm from the top edge of the workpiece

Drilling depth: max. 38 mm

Direction of rotation: left

Speed: 1500 rpm to 5000 rpm, frequency-controlled

Drill chuck: 10 mm

Total drill length: 70 mm

Drill diameter: max. 20 mm

1 horizontal drilling unit with 2 spindles

in Y direction

Drilling height in Z direction: max. 38 mm from top edge of workpiece

Drilling depth: max. 38 mm

Direction of rotation: clockwise

Speed: 1500 rpm to 5000 rpm, frequency-controlled

Drill chuck: 10 mm

Total drill length: 70 mm

Drill diameter: max. 20 mm

1 tool change spindle 9 kW - HSK F63

Speed range: infinitely variable 1250 - 24000 rpm, programmable

Anti-reb: frequency-controlled three-phase motor

Power at the tool: max. 7.5 kW / 9 kW in continuous and intermittent operation

Cooling: liquid circulation cooling

Tool changer magazine for 8 positions

(plate changer)

Tool weight: max. 5 kg total weight

Magazine capacity: max. 100 mm when fully loaded (8 milling tools), max. 160 mm with smaller tool diameters or free space on the secondary positions

Changeover time: approx. 12 - 18 sec. Chip to chip

WoodWop

HSK 63 combination unit Drilling / milling / sawing

Drilling depth: max. approx. 50 mm

Drill chuck: for ER 25 collet

Milling cutter diameter: max. 20 mm

Milling depth: max. approx. 50 mm

Milling cutter chuck: for ER 25 collet

Saw blade diameter: 150 mm to 180 mm

Cutting depth sawing: max. 40 mm

Saw blade thickness: max. 8 mm

Saw blade holder: 30 mm mounting hole, 4 auxiliary holes 5.5 mm diameter, pitch circle 52 mm diameter

Speed: max. 15,000 rpm programmable

Rotation range: 360 degrees

Unit holder: HSK63F cone

HSK 63 lock case D=20 mm, with blow-off nozzle

Direction of rotation: right/left

Speed: max. 12,000 rpm

programmable

Tool holder: Weldon chuck 20 mm

Tool clamping length: max. 125 mm

Total tool length: 170 mm

Unit mount: HSK63F cone

Max. milling cutter diameter: 20 mm

Note:

The technical data and descriptions are copies of the order confirmation at the time. The information is for informational purposes only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia