BrandVITAP

typeGROOVING

stateNew

stock number1110026

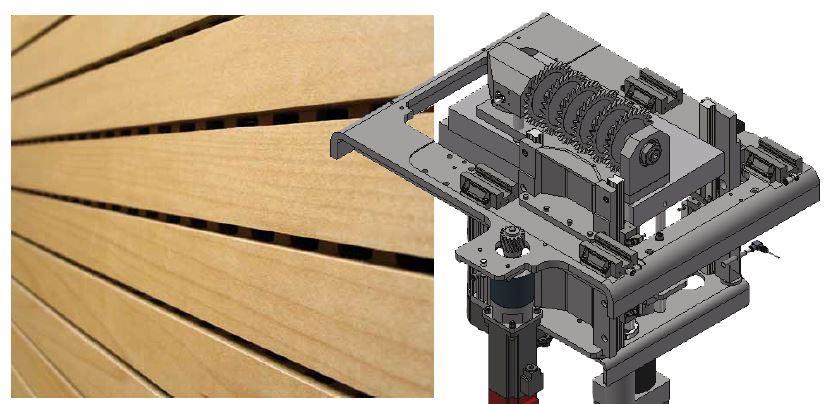

- Panel processing with a shaft á 7 saw blades

- No limits for panel length

- available in combination with the Vitap Acoustic

Questions about this machine

Grooving machine for throughfeed process

Brand: Vitap

Type: Grooving

New machine

For the processing of acoustic panels

Processing unit:

- Shaft with 7 presettable saw blades, distance 30mm.

- Blade thickness 4mm

- Rotation of the shaft , 7000 rpm.

- presetting with rapid hook HSK

- Max diameter of the blade 125mm

Workpieces:

- Max. thickness of the panel 50mm

- Max weight of the panel: Kg 50

- Max panel size : X no limit, Y 1200 mm, Z 50 mm

- Min panel size: X 400 mm, Y 300 mm, Z 12 mm

- Panel feeding speed : 25m/min

Characteristics:

3 controlled axes:

- X Axis - Panel movement with two dinamic clamps

- Y Axis - Grooving head movement with pinion and precision rack

- Z Axis - Movement with screw at spherical recirculation

- Newly patented, high rigidity operating unit movement on Y and Z axis.

- Constant side pushing to keep the 0-line

- Positioning axis X with direct motor drive, Y with toothed rack drive, Z- with ball screw

No limit in length

CE STANDARDS

Easy TPA programming

- The grooves are displayed on a virtual workpiece

- You can set the reference point exactly by entering or easily via mouse click

- Software dedicated for programming and optimization;

- Fast optimization program by inserting only the following data: bit diameter, Center distance, X axis dimension of the pattern, Y axis dimension of the pattern

- User's interface WSC with Lister, parametric tools and parametric set up

- Graphics programming CAD TPA EDI32, base version

- Set up parameters

- Working Path Configuration

- Data Entry Form with graphic support on major transactions

- Macro Programming

- Basic data always visible on screen

- Jobs List

- Cross Control between parameters and the working program

- Control: Full Parametric

- PC to support optimization programs with high speed

- Monitor LCD TFT 20"

- Usb port for loading programs run on a station in each office

- 3 levels of access with passwords (operator-supervisor-assistance)

- Saving all files with all data

Inclusive:

- 22 Point Greasing pump

- Office software

Optional for an extra charge available:

- 2 kg grease cartridge LIKO EPO

- 400 g GS Artic cartridge for machine heads

- 400 g EP0 grease cartridge for machine sliding block

- Bar code reader

- Frontal and rear rollers for long panels

- Shaft (without saw blades)

- Air conditioner for electric panel

- Voltage stabilizer

your contact person

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia