BrandALBERTI

typeBMF

stateNew

stock number1110170

- Equipment for automatic insertion of fittings, plinth parts, drawer runners and many more.

- Can be equipped with automatic screwing devices, glue specifications and press-in tools.

- Plant expandable with many possible hardware feeding stations.

Questions about this machine

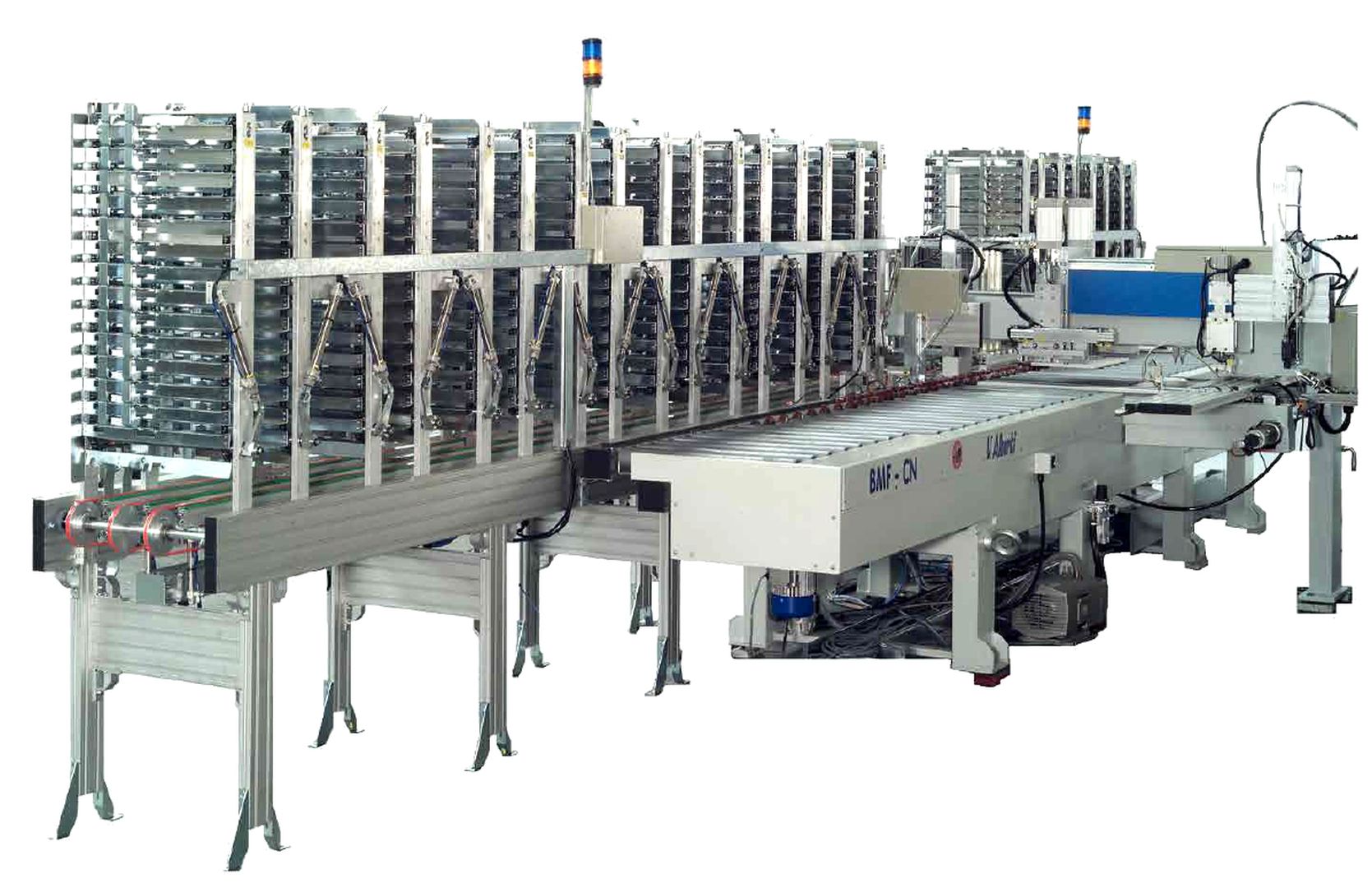

CNC assembly line

Brand: Alberti

Type: BMF

new machine

Equipment for automatic insertion of fittings, plinth parts, drawer runners and many more.

Can be equipped with automatic screwing devices, gluing indications and press-in tools.

Plant expandable with many possible hardware feeding stations.

This Alberti line can be customized according to your specifications.

Machine bed made of welded steel tube structure, the upper part is made of aluminum frame.

Components of the line:

- Feeding

- Processing zone with transport rollers

- destacking

Work table:

- Driven PVC rollers at the inlet.

Usable length: 2500mm, usable width: 840mm

- Reference table with PVC rollers

Usable length: 2500mm, working height: 840mm, adjustable +/- 30mm

- Driven PVC rollers at the outlet

Usable length: 2500mm, usable width: 840mm

- Vertical workpiece clamps, autom. adjusted to workpiece thickness

- Automatic zero point detection in X-direction at workpiece start and end

- Lamp to indicate workpiece clamping and machining mode

- Workpiece release for position correction

Technical data:

Working dimensions:

- min. 300x130x12mm

- max. 2800x900x50mm

Geometry: length > width / length = width / length < 20% width

Max. programmable speeds:

- X axis 100 m/min.

- W axis 20 m/min.

- Y-axis 50 m/min.

TPA-Albatros software

Software designed for:

- Control and creation of programs

- production lists

- Synoptic representation of the work tables for support

- Graphical sequence: drilling and insertion and optimization of work cycles

- Graphic visualization of the workpiece sides to be machined

- Parametric programming

- Diagnostics input and output, program list

Dimensions: 7050x1950x2690mm

Optionally available:

- Uninterruptible power supply PC

- PLC functions for control of autom. feeding and destacking

- Barcode reader

- Drilling unit for fittings / rails / wall brackets

- Unit for inserting fittings

- Unit for inserting wall brackets

- Suction unit at the rail insertion unit

- Glue application unit

- Unit for inserting screws

- Unit for inserting shelf brackets

- Bearing insertion unit

- Unit for inserting adjustable feet

- Unit for inserting gables

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia