BrandVITAP

typeGALILEO 2

stateNew

stock number1110215

- Easy and versatile by means of TPA Software

- Intelligent DDT feeding system

- Vitap Bar Nesting - efficient and time saving

Questions about this machine

CNC processing centre

Brand: Vitap

Type: Galileo 2

New machine

Create great things on small space - the best kind of using 5m² production space

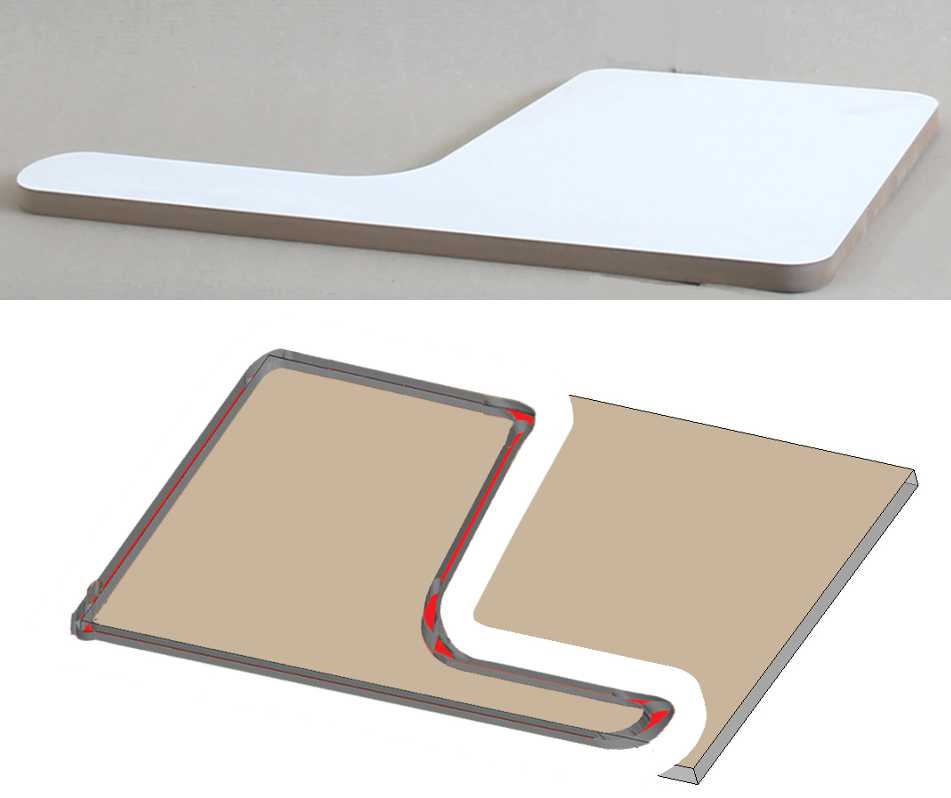

With this 3-axis machine you can drill, mill and groove in throughfeed.

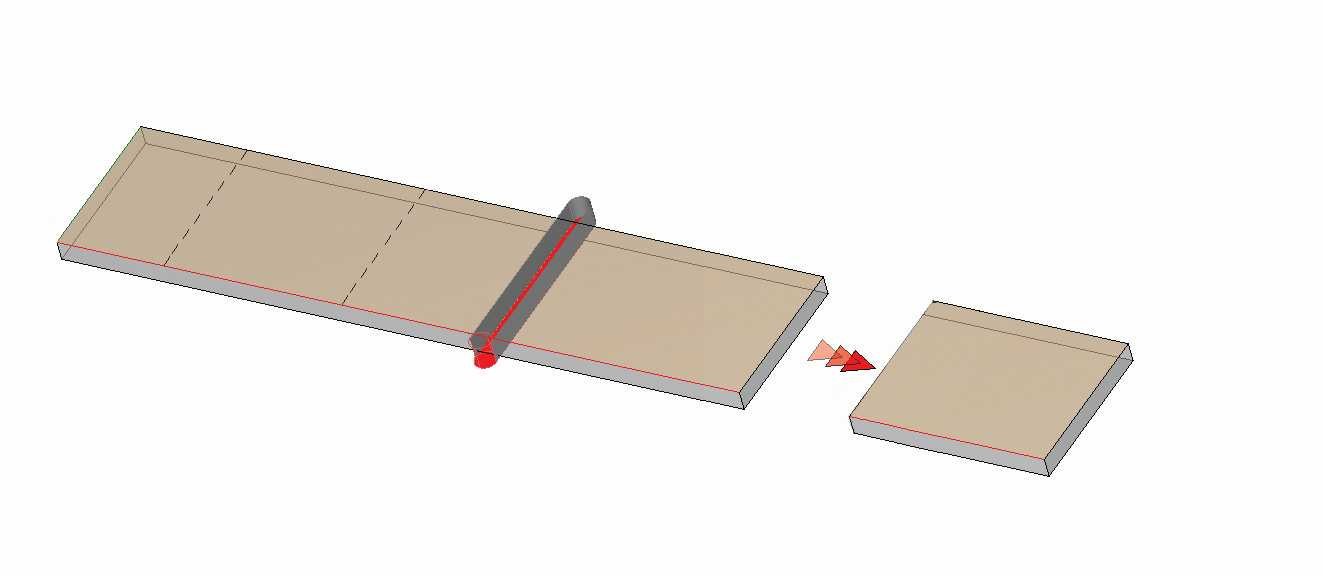

Vitap Bar Nesting - efficient and time saving

- This patented Software processes whole corpus elements out of one longer workpiece.

- Just insert the workpiece and when you take the first finished element, the machine contues with the processing of the next element

Easy beginn with CNC programming:

- TPA makes it easy: drillings, grooves, linear millings, form millings or the millings of letters

- The CAD Software shows the processings on a virtual workpiece

- Good overview about all processings on the single sides of the workpieces

- Mirror function for parallel processings on other positions

- Choose reference points via entering the exact position or just via click on the virtual workpiece

- Monitor LCD TFT 20"

- USB-Port

- Cut optimization software

- Macro programming

- DXF-File Import

- Office software

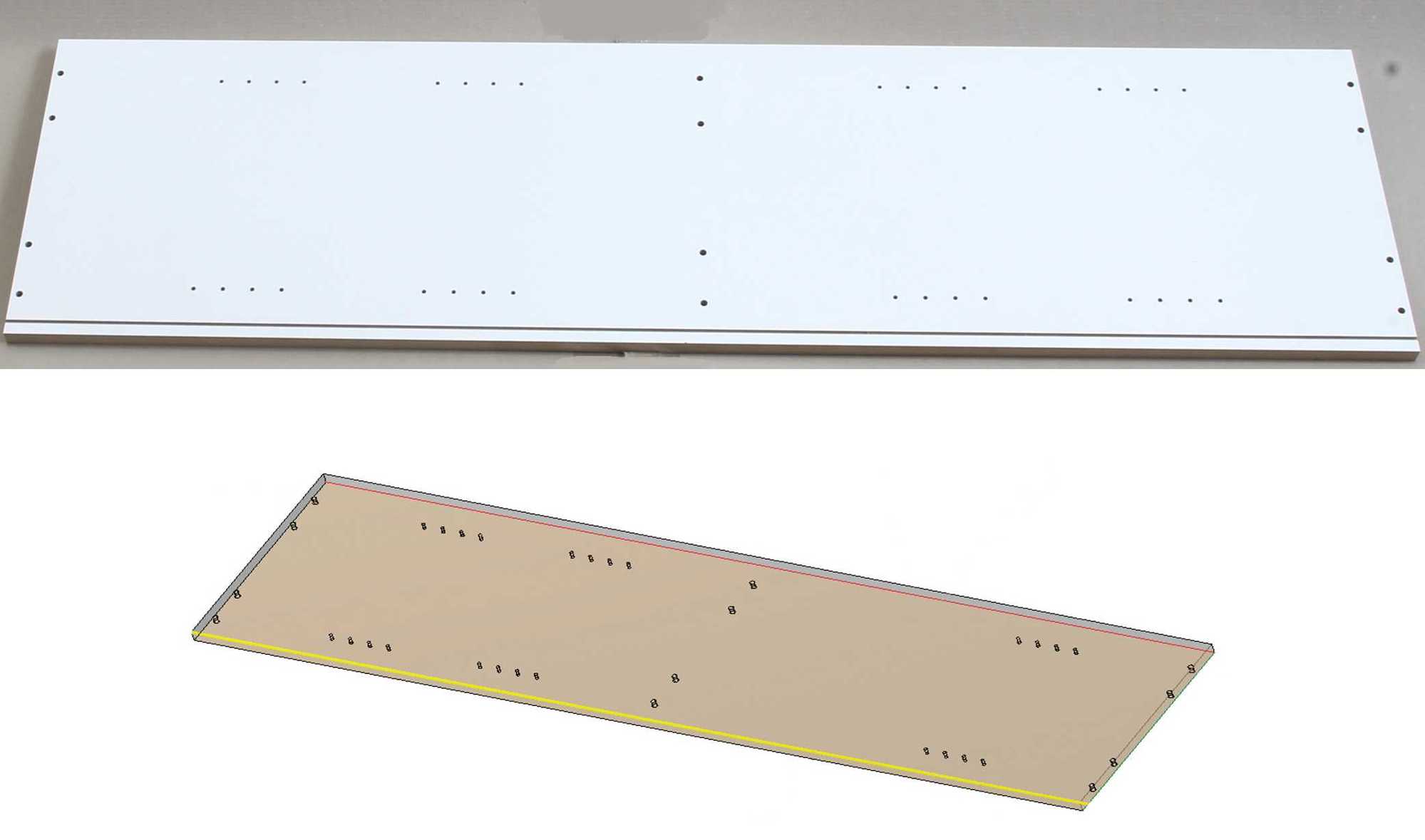

The DDT-feeding sytem (double dynamic transport)

- 2 Clamps make the interruption free workpiece transport possible.

- The operator insert the workpiece to the stop.

- Then the 2 clamps take the workpiece and position it absolutely exactly.

- During the process both clamps are communicating, so clamp 2 closes before clamp 1 opens.

- This is why the feed is continous at linear millings as well

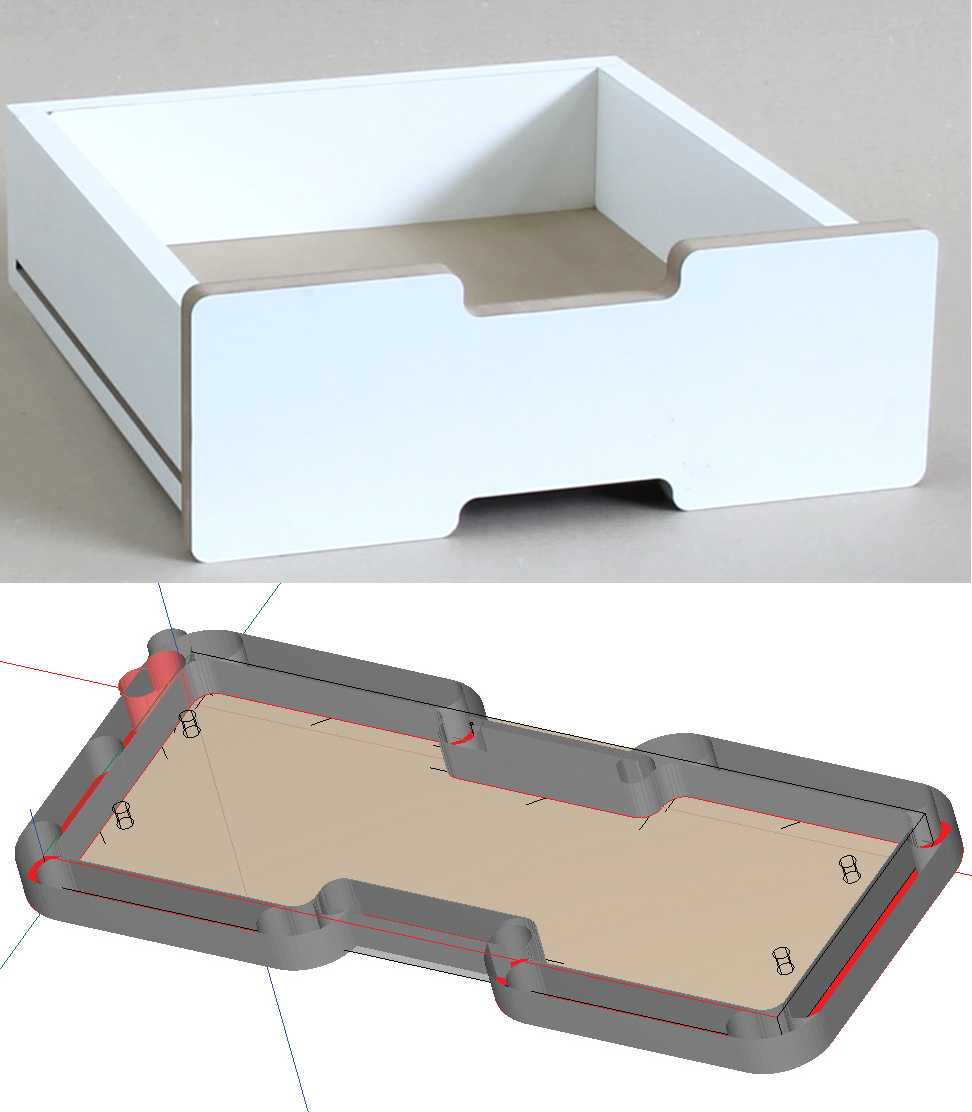

Processing unit:

- 9 single selectable vertical spindles

- 2+2 horizontal spindles in X-direction

- 2+2 horizontal spindles in Y-Richtung

- 3,3 kW Main spindle, ER 32, 24000 rpm.

Technical data:

- Min. workpiece dimensions: X 270mm, Y 185 m, Z 3mm

- Max. workpiece dimensions: X unlimited, Y 920 m, Z 50mm

- Max. workpiece weight: 50 kg

- Spindle rotation: 3600 UpM

- Saw blade rotation: 7000 UpM

- Max. vertical drilling depth: 43mm

- Max. vertical diameter 35mm

- Max. horizontal diameter 12mm

- Motor 1,7 kW

- Machine dimensions: 2900x1650x1890mm

Inclusive:

- Grease pump 22 Point

- Tool-Kit for production start

Optional available for an extra charge:

- 2 kg grease cartridge

- 400 g S Artic cartridge for machine heads

- 400 g grease cartridge for machine sliding block

- Additional top pressure

- Barcode laser

- Frontal- and rear panel support

- Narrow piece guidance, workpiece width min. 70mm

- Air conditioning for switch box

- Voltage stabilizer for PC

your contact person

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia