CNC Machining Center

Manufacturer: Intorex

Model: TKC-1500

New Machine

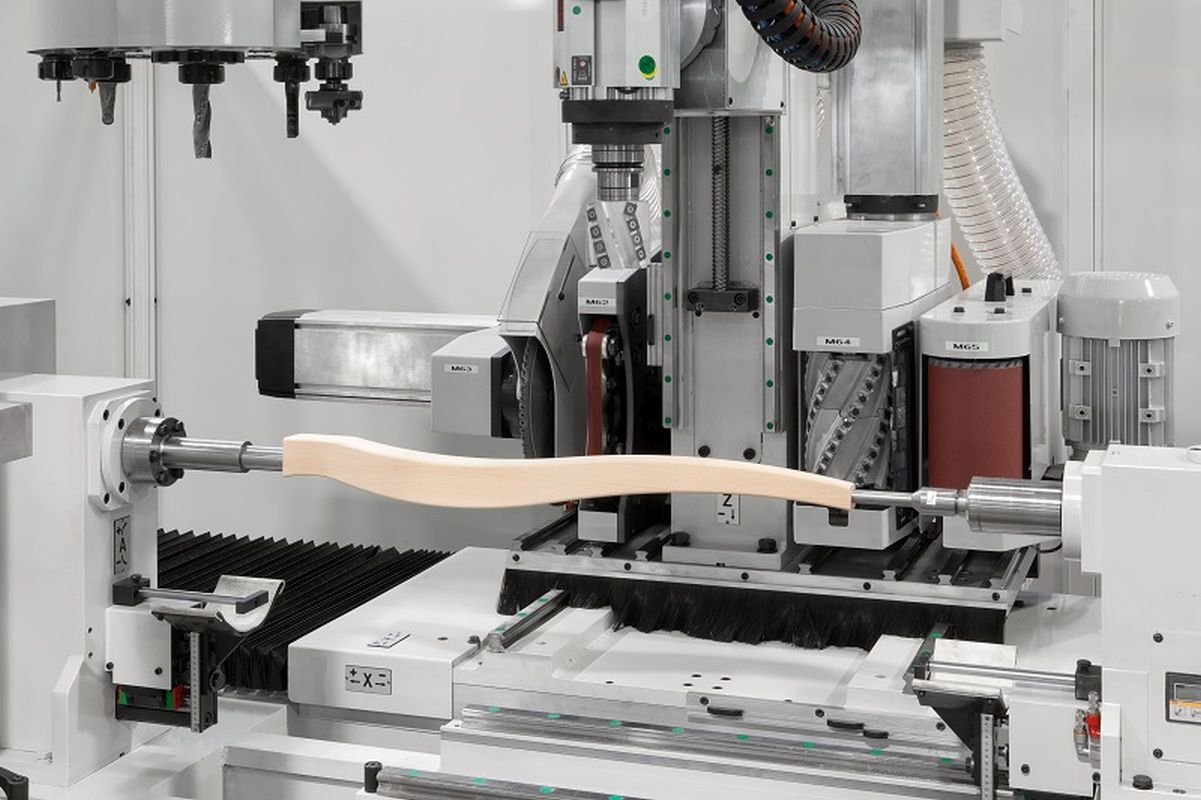

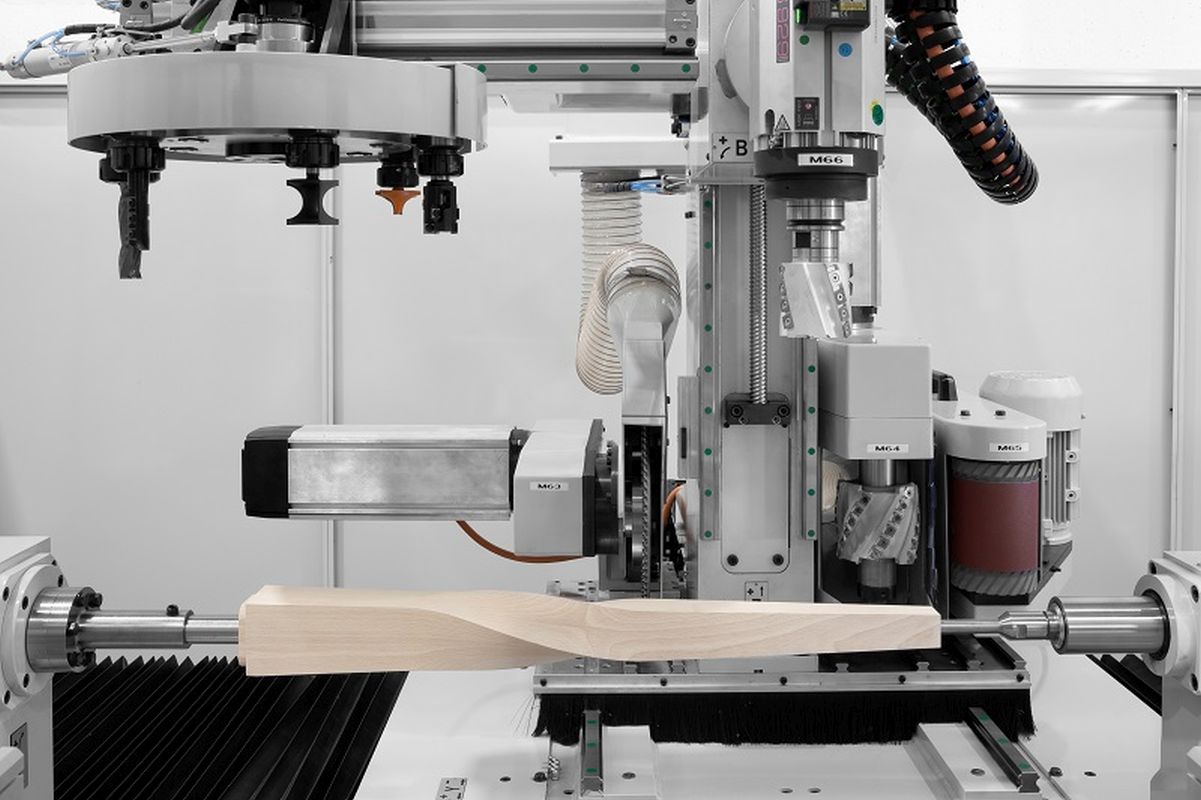

TKC-1500 Machining Center with 5 Interpolated Axes

INCLUDED STANDARD EQUIPMENT:

Digital Osai Open 6-axis control system with EtherCAT interface.

Industrial panel PC 15.6" IP65 front:

Fanless

15.6" resistive touchscreen, 1366x768 resolution

Intel Celeron J1900 Quad-Core 2.0GHz processor

60GB Solid State Drive (SSD)

4GB RAM

Communication ports:

1 x USB front + 3 x USB

2 x Ethernet

1 x RS-232/422/485

1 x VGA

Audio – input/output

OS: Windows 10 IoT Enterprise – Embedded

Technical Specifications

IntorEDIT 3D – CAD-CAM software developed by INTOREX for designing parts and post-processing machining programs.

Electrospindle (Axis B):

Electric motor with 7.5 kW power and rotational speed from 0 to 22,000 rpm, controlled by the CNC.

Automatic tool changer (HSK F63) and electric fan cooling.

Headstock (Axis A):

15.3 kW motor with interpolation and positioning over 360°, continuous rotation speed from 0 to 1500 rpm, CNC-controlled.

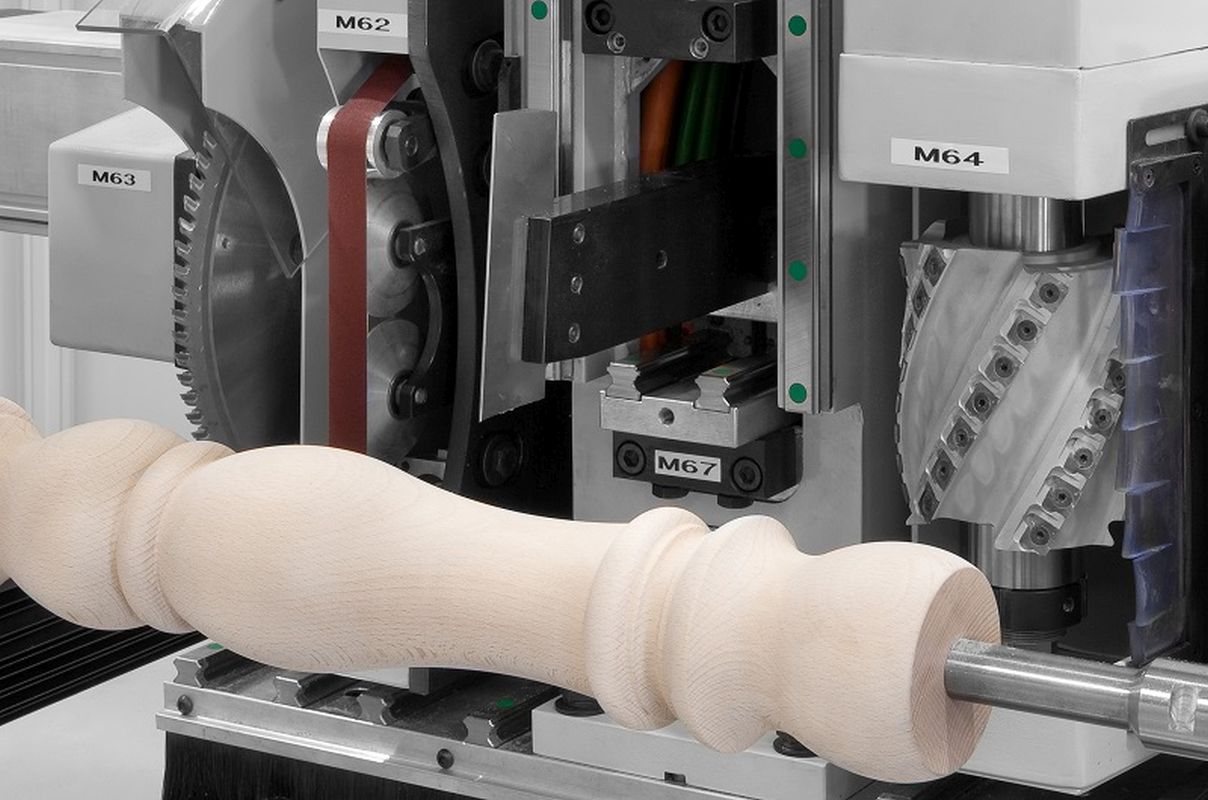

Turning or milling head with saw blade (Axis Y, Unit Y2):

Equipped with a 9 kW motor, variable speed from 1000 to 4500 rpm controlled by an inverter (saw blade not included).

Milling head with milling tool (Axis Y, Unit Y3):

Equipped with a 9 kW motor, variable speed from 1000 to 5000 rpm controlled by an inverter (milling tool not included).

Sanding head (Axis Y, Unit Y4):

With a 2.2 kW motor and 3000 rpm rotation speed.

Automatic feed unit for workpieces up to 150x150 mm in cross-section and 1500 mm in length.

Rotary tool magazine with 8 tool slots (Axis Q):

Includes 6 tool holders with HSK F63 cone type (tools not included).

Unloading unit and part removal via conveyor belt.

Fully enclosed safety guards, consisting of a pneumatically operated front door that opens/closes in sync with the work cycle, rear panels, and fixed side panels.

The protective enclosures comply with EU standards.

Set of two "anti-shock" pneumatic cylinders to prevent part damage during unloading.

Headstock support for interchangeable centers.

Cylindrical headstock, diameter: 30 mm

Tailstock diameter: 15 mm

Abrasive belts, grit 150, dimensions: 170x1500 mm

Maintenance tools, hydraulic oil, and operating manual included

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia