BrandVITAP

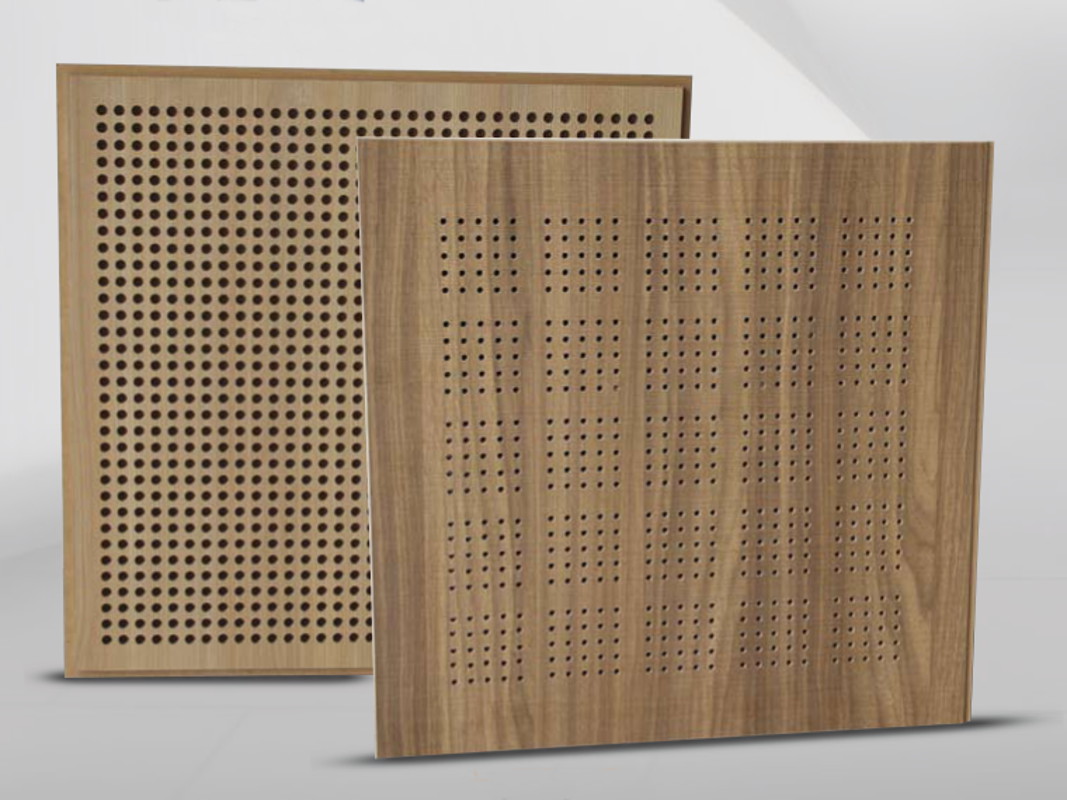

typeACOUSTIC

stateNew

stock number1110025

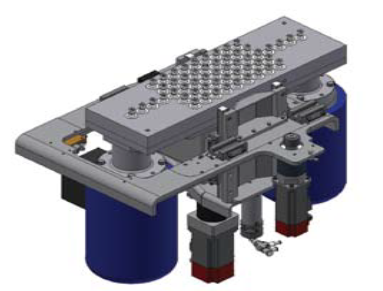

- Monobloc-boring head:

55 spindles, spindle distance 32 mm

- workpieces max.: X=unlimited, Y=1250mm, Z=50mm

Questions about this machine

Troughfeed boring machine

Make: VITAP

Type: ACOUSTIC

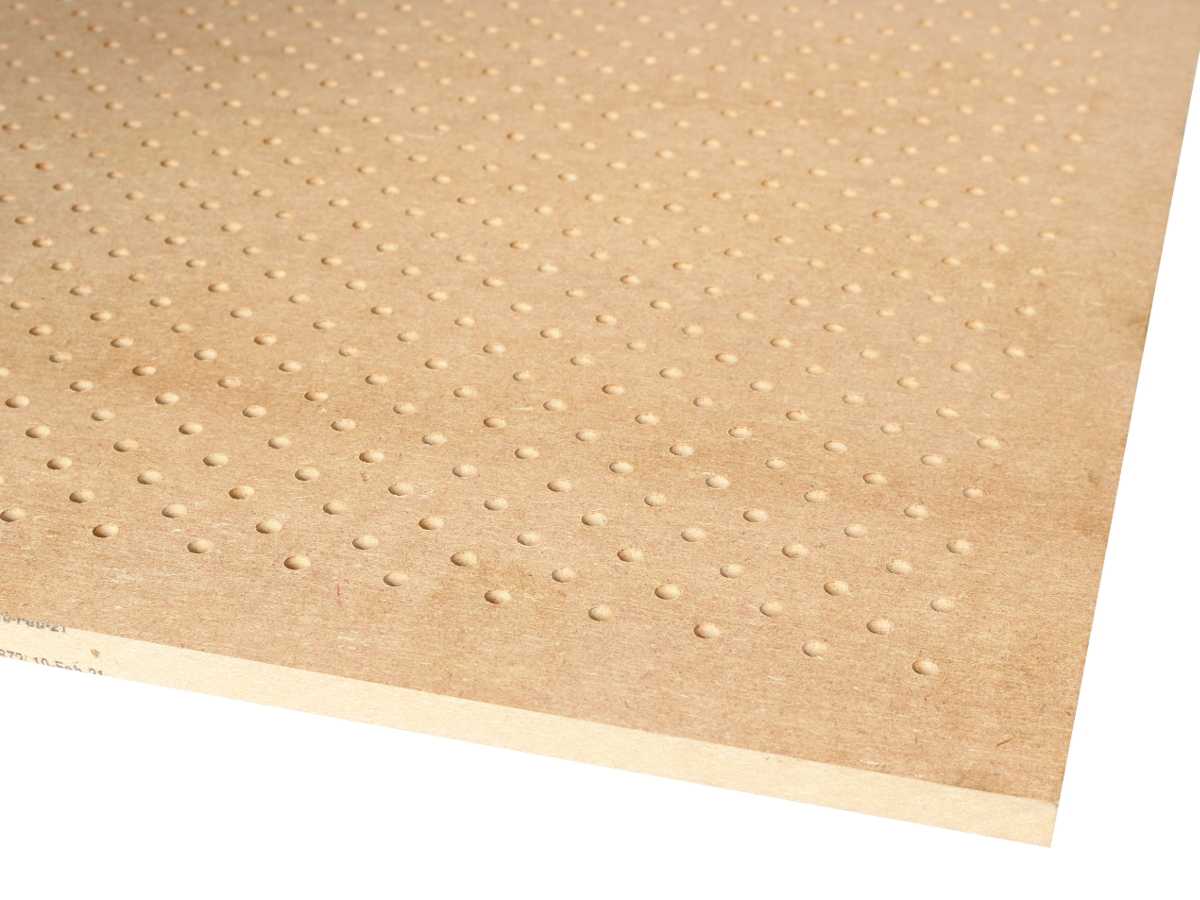

For creation of acoustic panels for noise reduction

Boring machine with through feed panel, boring from the bottom and automatic panel return to the operator.

Three controlled axes:

- X Axis - Panel movement by means of a strong pneumatic clamp

- Y Axis - Boring head movement

- Z Axis - Panel boring

- Newly patented, high rigidity boring head movement on Y and Z axis.

- Constant Side pusher: Side pusher with constant preload for perfect positioning of the panel on the machine zero point.

- New frontal and more user friendly tool change system

No limit in panel length

High productivity and flexibility

- The drilling head processes several holes at the same time

- Different grids are possible also drilling grids with shift

- Different drilling heads are optional available

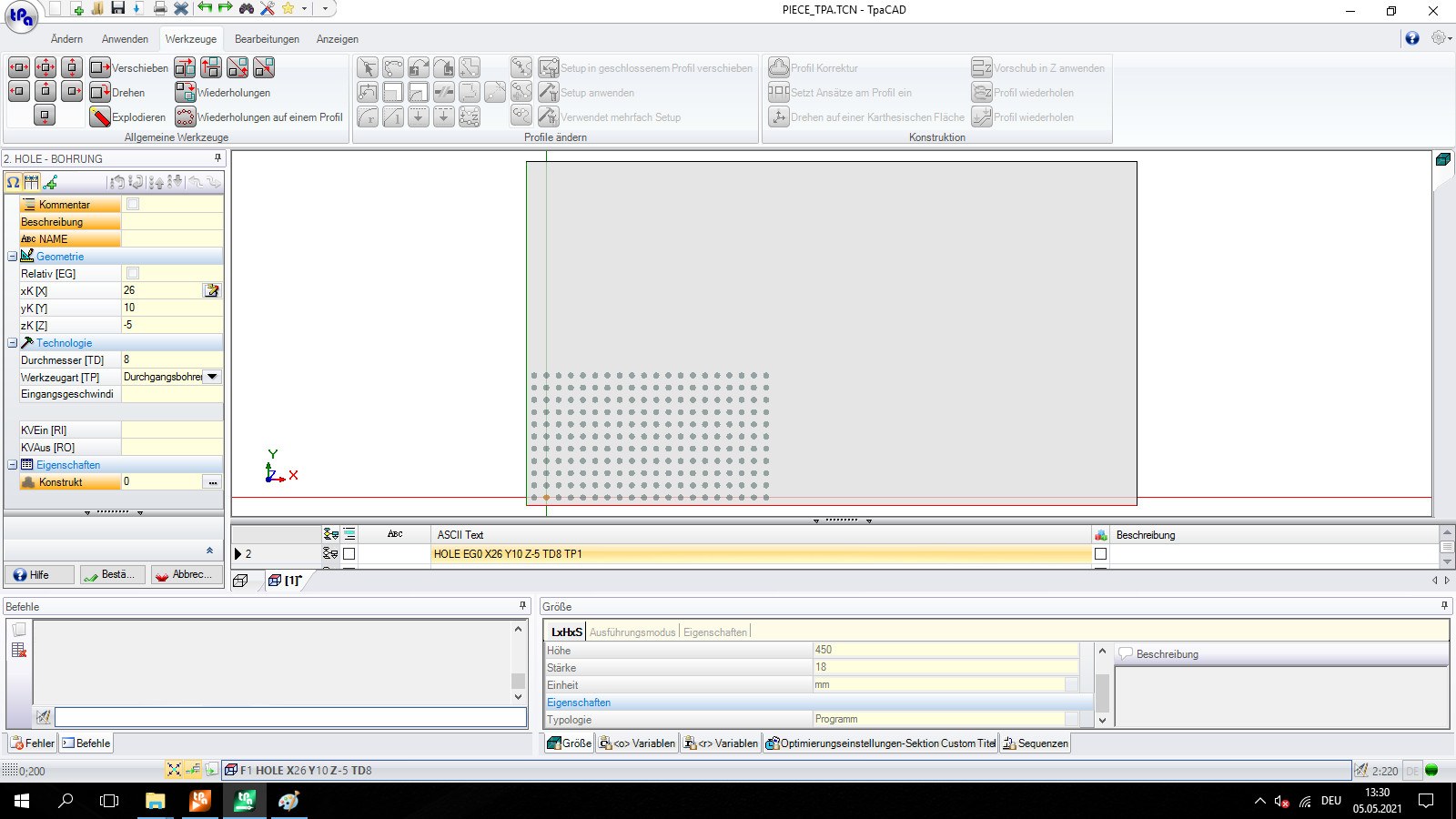

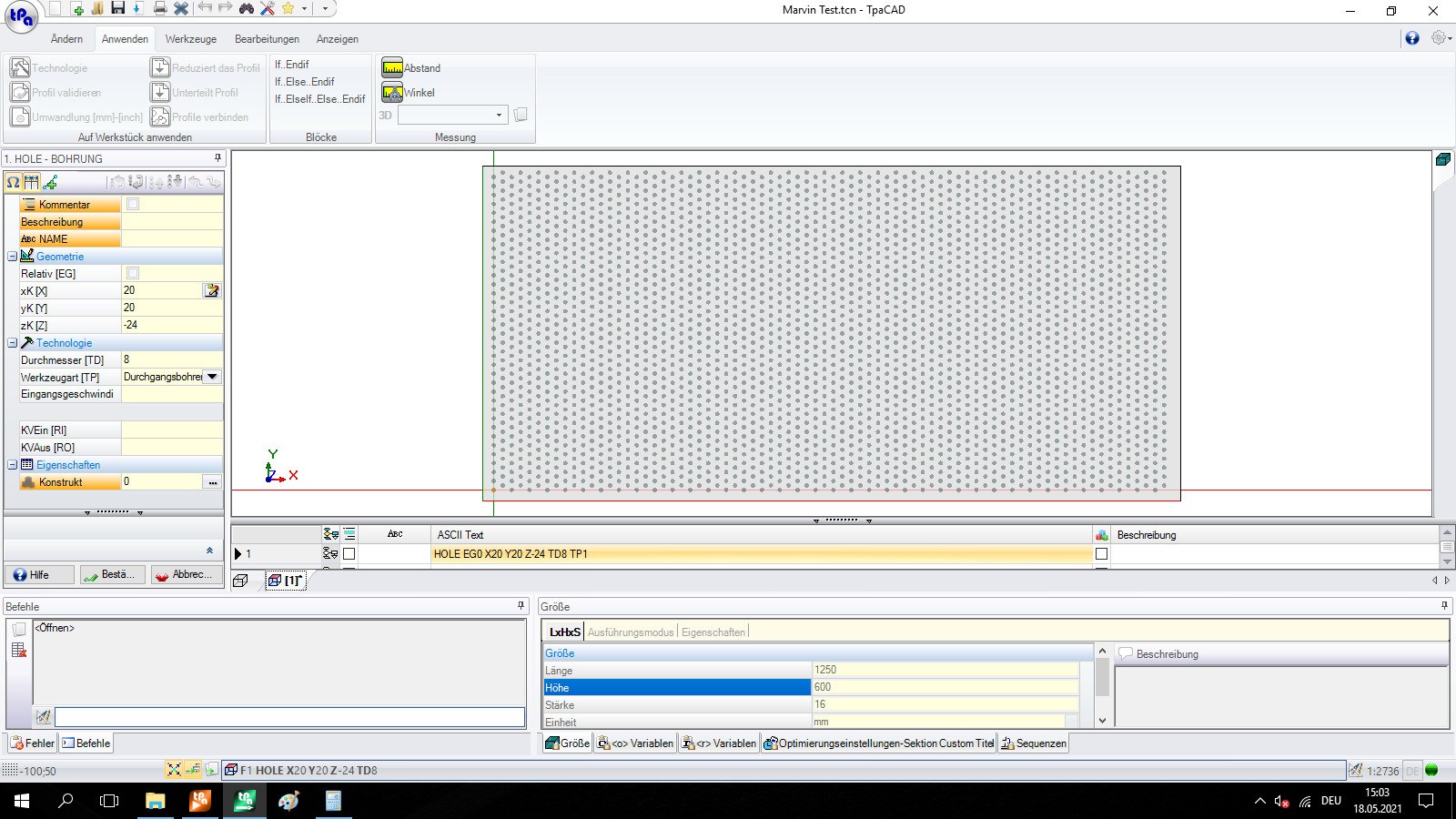

Easy TPA programming

- Control: Full Parametric

- Software dedicated for programming and optimization of the drilling;

- Industrial pc for better programming performance

- Monitor LCD FT 20"

- Simple programming

- High productivity and flexibility

Drilling head

- 55 spindles, 32 mm grid

- 55 adaptors for quick chucks

- The heads rotate at 2800 rpm

- 2 Motors á 4 Kw

- 4 Vertical pressure clamp

Workpieces:

- Max. thickness of the panel 50mm

- Max weight of the panel: Kg 50

- Max panel size : X no limit, Y 1200 mm, Z 50 mm

- Min panel size: X 400 mm, Y 300 mm, Z 12 mm

CE STANDARDS

Options:

- 2 kg grease cartridge LIKO EPO

- 400 g GS Artic cartridge for machine heads

- 400 g EP0 grease cartridge for machine sliding block

- Bar code reader

- Frontal and rear rollers for long panels

- Procesor for the drilling optimization

- Quick chuck for 10mm bits

- Additional pressure device

- Switch box air conditioner

- Voltage stabilizer for PC

- 14 Point Greasing pump

Driling heads, optional available for an extra charge:

- 3x7 Spindles, 50mm grid

- 4x9 Spindles, 40mm grid

- 7x17 Spindles, 20mm grid

- 6x14 Spindles, 25mm grid

- 5x11 Spindles, 28,575mm grid

your contact person

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia