BrandALBERTI

typeSYNCRO-PLUS

stateNew

stock number1110171

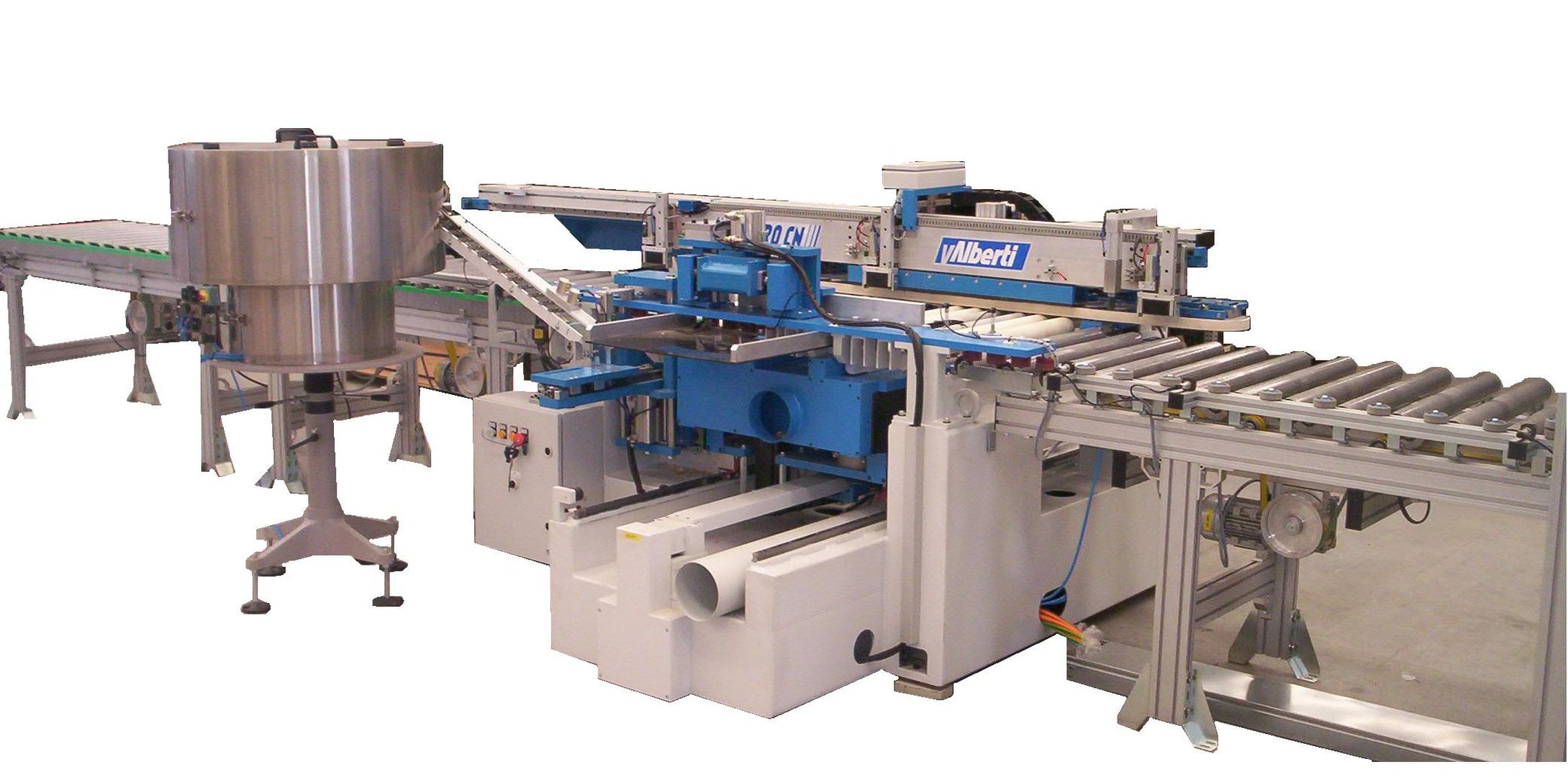

Line with 5 controlled axes for vertical drilling from below. Options also allow grooving, milling and insertion of fittings.

It is possible to combine this Syncro line very well with the BMF series of Alberti.

Questions about this machine

CNC drilling line

Brand: Alberti

Type: Syncro-Plus

New machine

Line with 5 controlled axes for vertical drilling from below. Options also allow grooving,

milling and insertion of fittings.

This Syncro line can be very well combined with the BMF series of Alberti.

Autom. or manual loading with longitudinal workpiece transport

Monolithic frame in welded strong steel

Independent control of all axes with drilling cycle optimization

5 independet asex

X1 Feed rate belt conveyor, 100 m/min

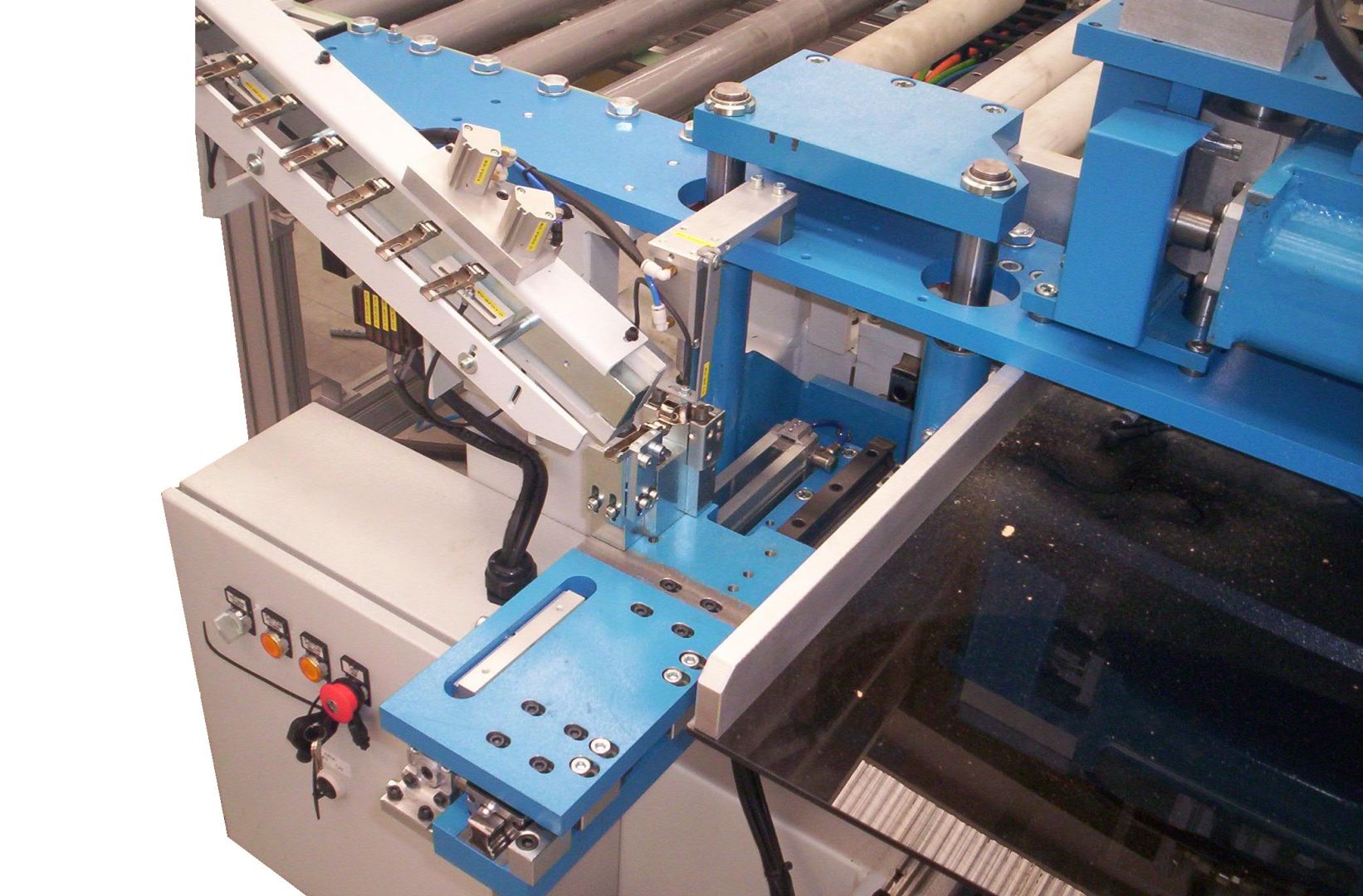

X2 Control of reference stops, 55 m/min.

X3 Workpiece transport control in relation to the workpiece width, 15 m/min.

Y Drill head control, 45 m/min

Z Machining depth control, 10 m/min

Remark:

Max. Workpiece dimensions: 3000x900x30mm

Min. workpiece dimensions: 300x130x12mm

Geometry of workpieces: Length > Width / Length = Width / Length < 20% Width.

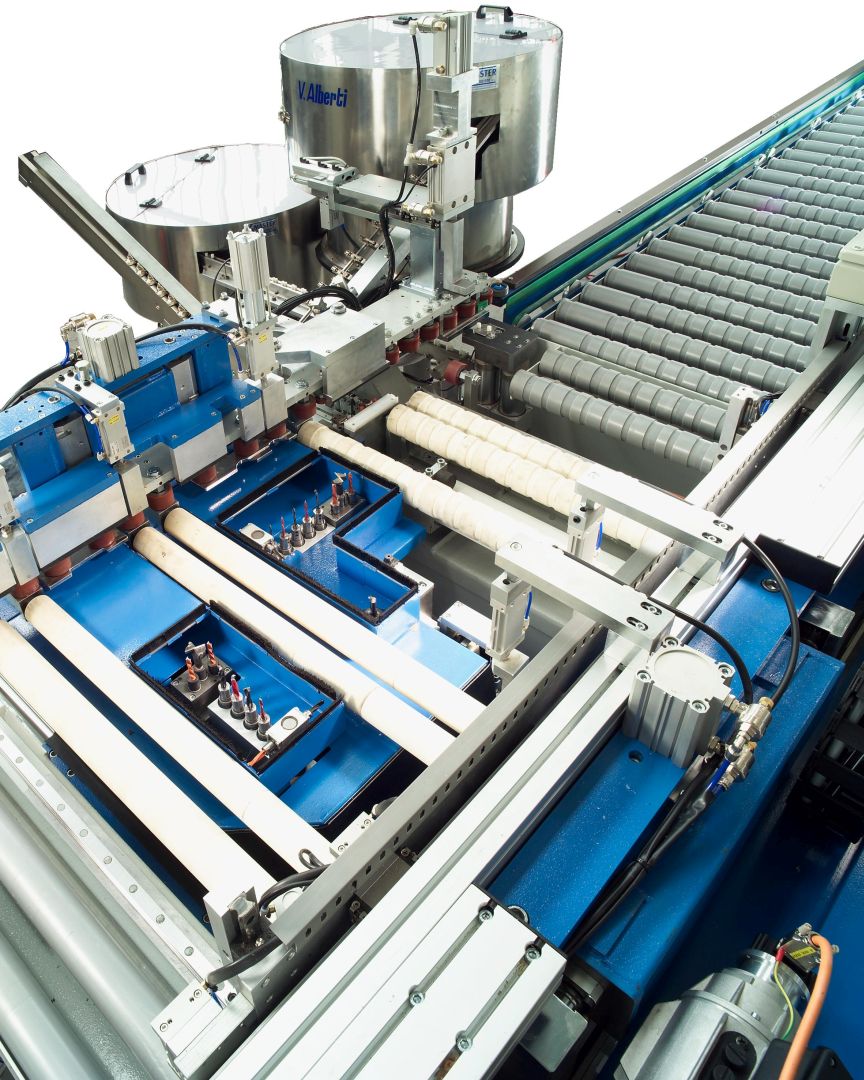

Machining head:

1 vertical drilling unit with 9 independent spindles in Y-direction, 32mm grid.

1 vertical drilling unit with 9 independent spindles in Y-direction, 32mm grid

Work table:

- Motorized roller conveyor for the infeed, PVC coated and inverter controlled.

- Workpiece clamping system with pneumatic cylinder

- Reference table integrated in the machine bed with rollers, PVC coated

- Motorized roller conveyor for the outfeed

TPA Albatros software

Optionally available at extra cost:

Drilling units:

Vertical drilling unit: 3 spindles for fittings, monobloc.

Vertical drilling unit: 18 spindles in Y; replaces the standard drilling unit with 9 spindles

Vertical drilling unit: 17 spindles in Y; replaces the standard drilling unit with 9 spindles

Vertical drilling unit: 3 spindles for hardware drilling, separately driven with 1.5 HP

- Horizontal drilling unit: 1+1 spindles in X-direction, 50mm drilling depth, max. 10mm Ø

- Horizontal drilling unit: 1 spindle in Y-direction, 45mm drilling depth, max. 10mm Ø

Grooving saw, separately driven, max. Ø120mm, 120000 rpm.

Milling cutter, 7,5 HP, 12000-18000 rpm, tool Ø 20mm.

fitting insert:

- single insert unit

- double insertion unit, for 110° and 180

- insert unit for plastic fittings

[b]Magazines:

- 6 magazines for a total of 30-35 fittings (depending on fitting type).

- Extension of the 6-fold magazine for 40-45 fittings

- Magazine with vibratory feeder for max 150 fittings

- Vertical magazine for 135°, max 20-25 fittings

- Runway magazine for 175 / 180°, max 20-25 fittings- Set Runway Magazine:

4 pieces for 175 / 180°, 18-20 fittings

- Preparation for vertical magazines and magazines with vibratory feeder

- Magazine with vibratory conveyor for plastic fittings

- Support and side pressure for door frames during stacking

- Supports for zero line guidance

- Driven belts for the transport of door frames and drawer fronts

- Uninterruptible PC power supply

- PLC for control of autom. loading and destacking

- Dongle for offline editor functions

- Barcode reader

- Control cabinet air conditioning

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia