BrandCOMEC

typeFRONTAL CN 1500 2S

stateNew

stock number1110201

For point-to-point throughfeed machining

With 2 working units for drilling and milling

With automatic loading and workpiece return system

Questions about this machine

CNC Drawer fronts processing machine

Brand: Comec

Type: FRONTAL CN 1500 2S

New machine

for point to point drilling and milling, with automatic loader

and pieces return to the operator

Structure

Frame of electro-welded steel sheet of heavy-duty construction

Loading system

1 fix left shoulder and 1 mobile right shoulder on which are fixed the loader, magazine and locking system.

Manual adjustment of the mobile shoulder on ball bearings slides with measure indication by digital display.

Automatic loader with vertical adjustable magazine.

Pieces advancement system step by step with 2 working stations, complete with locking cylinders on each station.

Pieces return system

Pieces return system composed with:

1 transversal motorized belt kW 0.37.

2 ejector cylinders.

1 longitudinal, lateral motorized belt kW 0.37.

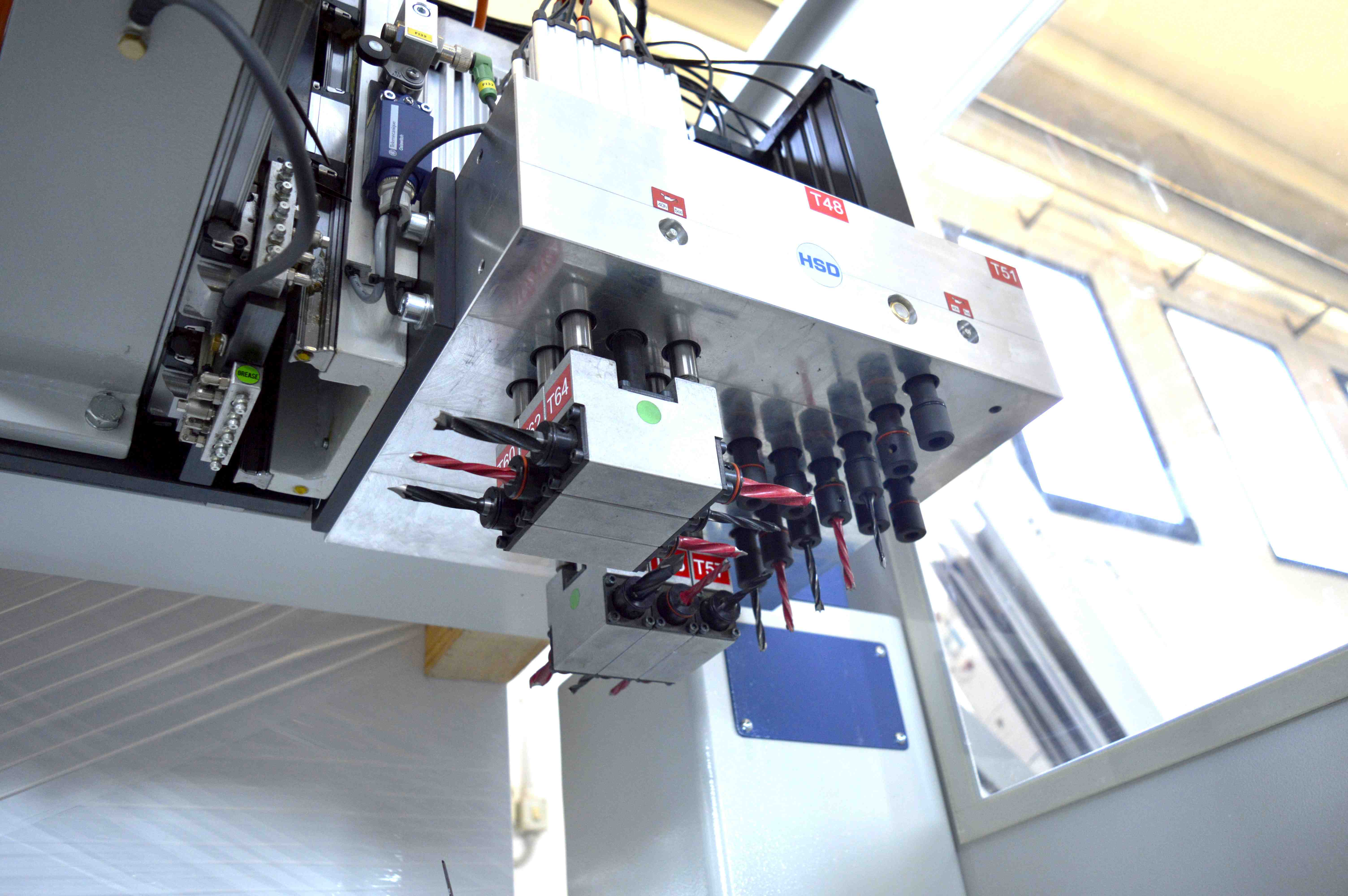

1st Working station: vertical-horizontal Point to Point drilling

1 vertical point-to-point drlling unit controlled by NC son X,Y and Z axes

motor kW 1.7 / 4.350 rpm.

Point to point drilling head, with following drilling pattern:

11 vertical spindles in cross placed (7 drills longwise Y axis and 4 drills longwise X axis),

center distance 32 mm,

3+3 horizontal double-exit spindels left-right, center distance 32 mm in line, for lateral drilling,

3+3 horizontal double-exit spindles operator-machine side, center distance 32 mm in line, for horizontal drilling.

Tools shank diam. 10 mm.

2nd Working station: milling and grooving

1 rear milling group for channels processing, controlled by NC on X axis

with useful run 1500 mm. Adjustable by means of screw and mechanical counter (SIKO) on Y and Z axes equipped with following indepent units:

- 1 horizontal electro-spindle motor kW 1.8 / 12000÷18000 rpm, speed adjustable with inverter and blade tool Ø 140 mm.

- 1 vertical electro-spindle motor kW 3.3 / 12000÷18000 rpm, speed adjustable with inverter and milling tool with chuck ER 32.

Control unit

Stand-alone electrical cabinet: placed separately from the machine to its side.

Control unit with 12" colour touch-screen display

2 USB connectors / 1 ethernet socket / Windows 10 iot operative system

Software with parametric programming assisted by 3D working models.

Drilling cycle automatic optimization

Page, within the software, dedicated to the setting parameters of the tools

Protections in caompliance with CE safety rules.

Volt 400/50 Hz.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia