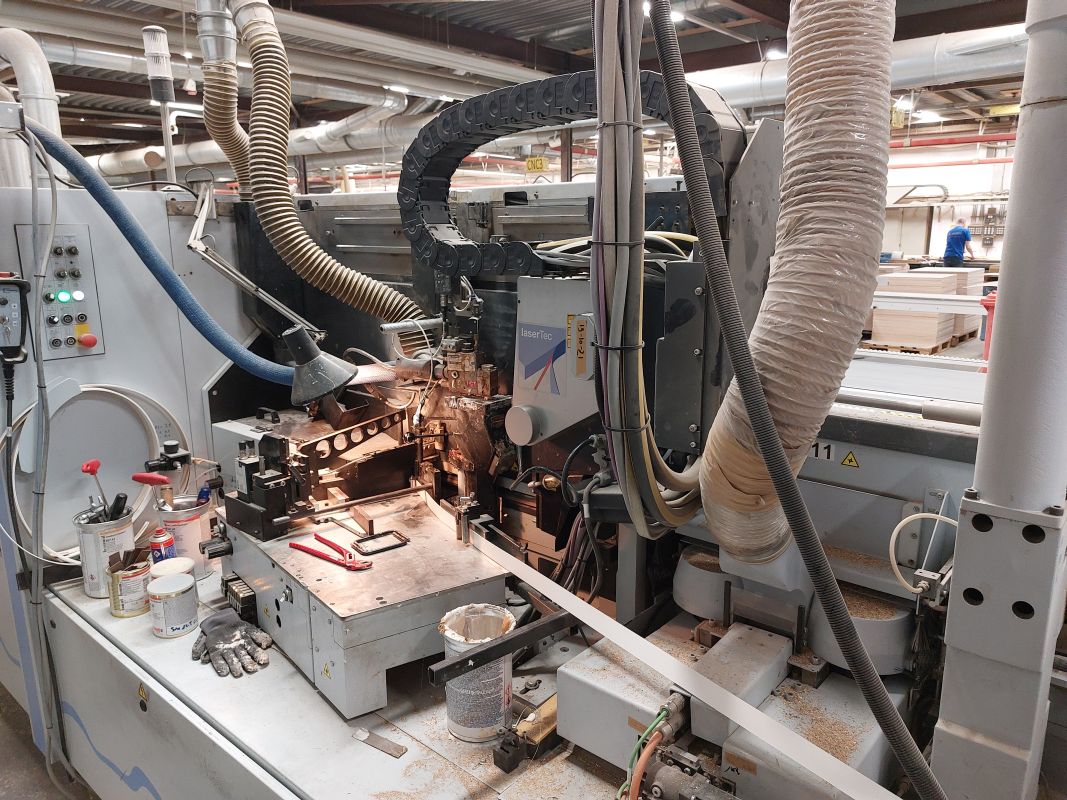

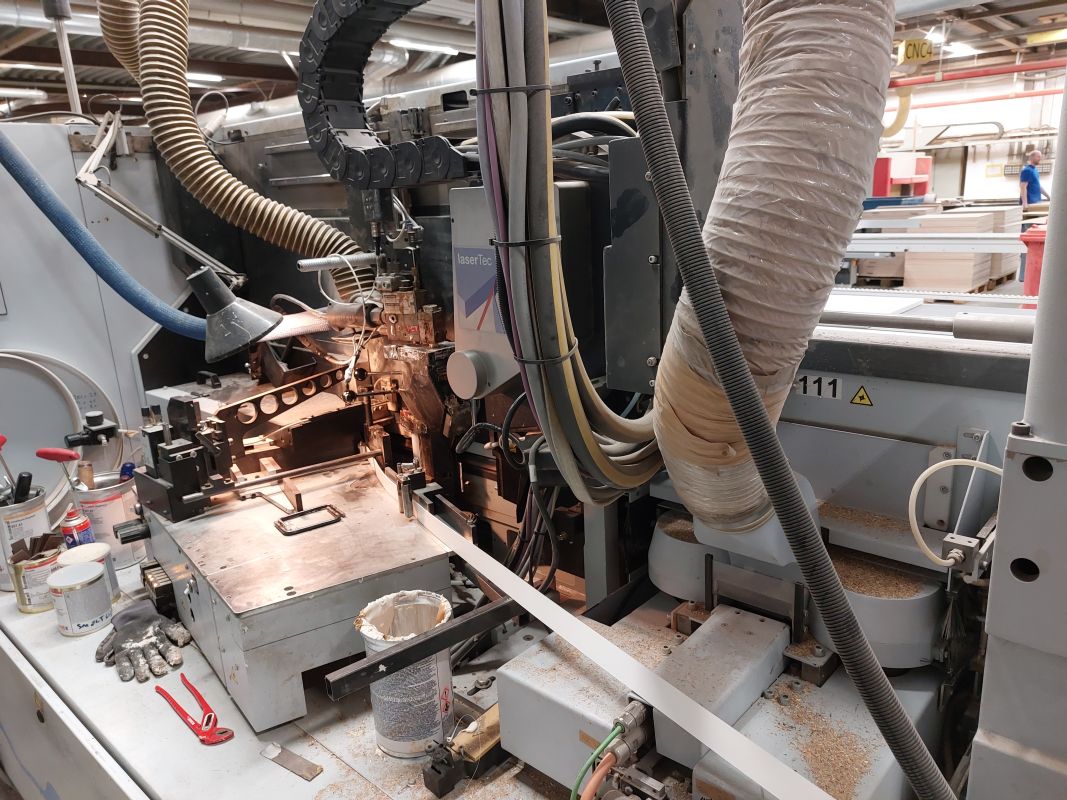

BrandHOMAG

typeKAL 330/9/A6/L

stateUsed

stock number0401676

year2011

One-sided edge banding machine for processing straight workpiece edges and for gluing and reworking various edge materials in longitudinal and transverse throughput.

- with Lasertec and PU gluing

- with vacuum portal returning system Barbaric

Questions about this machine

Used single-sided edge banding machine

Brand: Homag

Type: Profi KAL 330/ 9/A6/L

Year of manufacture: 2011

Feed speed Infinitely adjustable 18-25 m/min

Release agent spray unit top/bottom

- To reduce surface contamination.

Jointing unit KAL300/S2

- 2 motors, each 3 kW, Hz 9000 1/min

- Motor shaft Ø 30x68 mm, KN

- Electropneumatic control of both motors for joint milling.

- Automatic adjustment of the joint milling cutter to the center of the workpiece.

Melting unit with granulate container

- Granulate container 12L

- Level control of the melting quantity

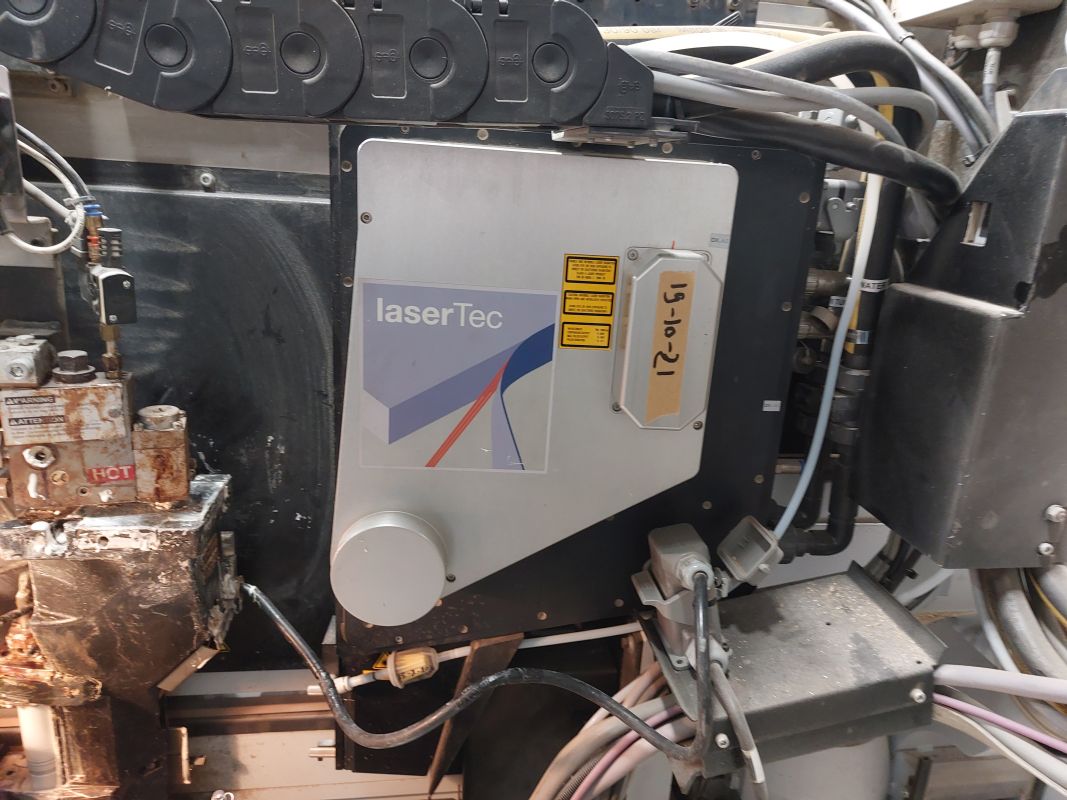

Lasertec activation unit standard

- The gluing unit is designed so that it can be used with either EVA/PU adhesive or LaserTec.

- Manual conversion from LaserTec to PU/EVA

Magazine 1 roll

- For solid edges, strip goods, and roll goods

- Automatic strip separation via vacuum suction cup

- 1 edge feed

Pressure zone C

- 1 driven pre-press roller, diameter 150 mm

- 6 post-press rollers, diameter 70 mm

Automatic adjustment of pressure zone Optimat:

- For automatic adjustment of the pressure zone for different edge thicknesses.

Application unit PU34 (interchangeable)

- Teflon-coated

- For processing PU adhesive, e.g. as granulate

HL84 chamfer/straight cutting unit, 0.22 kW

- For cutting excess material from the front and rear edges.

- 2 motors, each 0.22 kW, 200 Hz, 12,000 rpm

- Pneumatic adjustment for switching from chamfer to straight cutting.

Pneumatic adjustment of trimming motor:

- For electro-pneumatic adjustment of the trimming motors to 2 positions.

Pre-milling unit BF10 0.55 kW

- 2 motors one above the other, each with 0.55 kW, 200 Hz, 12,000 rpm.

Pneumatic adjustment of pre-milling unit:

- To 2 positions.

Multifräsaggregat MF21 0.55 kW automatic

- For chamfer milling of different edges up to a maximum edge thickness of 3 mm and for radius milling

R=2 or R=3 with a combination tool

- For automatic changeover between chamfering/radius milling and for moving sideways out of the working area

- 2 motors, each 0.55 kW, 200 Hz, 12,000 rpm with plug connection.

Cutting agent spray unit at the top

Shape milling unit FK31/30- cycles

- For machining the front and rear edges of the workpiece

- 1 motor 0.75 kW, 200 Hz, 12000 rpm

- Program-controlled changeover to 3 different radii and 15° chamfer

- Feed rate: max. 30 m/min

Free space for universal milling unit

MN21 automatic multi-blade

- For max. 5 different profiles

- Scanning from above, below, and from the side for chamfering or rounding pre-milled PVC edges.

FA11 top/bottom finishing unit

- For finishing the longitudinal edge, consisting of:

- Glue joint scraper

- Cleaning agent application top/bottom

- Using 2 spray nozzles

- Buffing unit

- Height adjustment with top pressure

Note:

The specifications and descriptions are a copy of the order confirmation at that time. Data are for information and are not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia