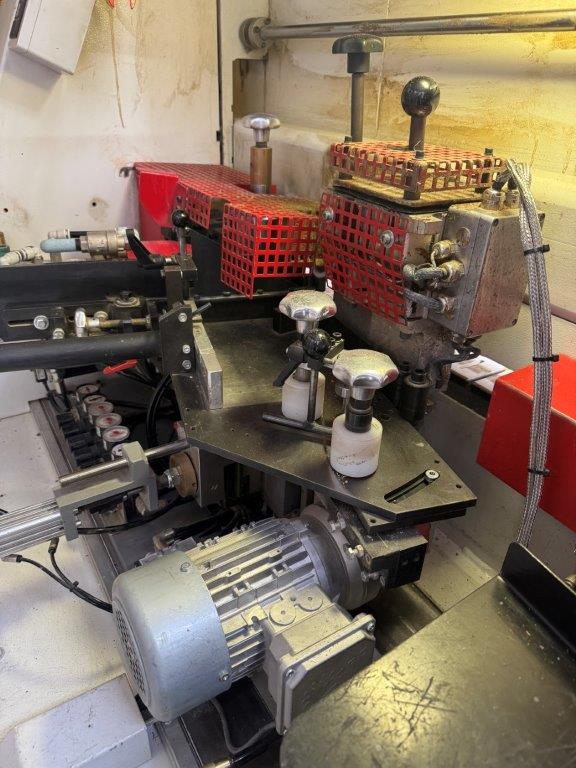

BrandIMA

typeAdvantage 310

stateUsed

stock number0401818

year2010

- Release agent specification top/bottom

- Joining unit and blow nozzle

- Cutting unit

- Copy trimming unit SKF-L

- Profile scraper unit

- Spray cleaning agent

- Self-scanning scraper unit

- Buffing unit

Questions about this machine

singel sided edge banding machine

Brand: IMA

Type: Advantage 310

Year of construction: 2010

Technical data

Workpiece

- Workpiece length: min. 150 mm

- Workpiece width: min. 65* / 150 mm

*with max. workpiece thickness of 25 mm

- Workpiece thickness: min. 8 mm, 12 mm with profile scraper blades

max. 40 mm (with MFA 08.346), 60 mm (with SKF)

- Smallest workpiece: 65 x 300 / 150 x 150 x 19 mm

- Machining allowance per workpiece edge: 0 - 5 mm (observe max. cutting cross-section)

- Workpiece shape: rectangular

- Material: chipboard, MDF

- Surface material: Direct coating (melamine resin paper), paper, foil, veneer

Edging material

- Roll material without foil:

Paper edges & plastic edges: 0.3 - 3.0 mm

Veneer edges: 0.5 - 3.0 mm

- Max. edge cross-section: 150 - 180 mm²

- Cut-to-length edge strips:

Strips: 3.0 - 8.0 mm

- max. strip cross-section: 520 mm²

- Edge height: min. 12 mm, max. 65 mm

- max. upper edge overhang: 2 mm

- Edge profiles

Paper edge: approx. 0.4 mm, bevel 15°

Plastic edge up to 3.0 mm, depending on radius tool

Milling strip flush up to 8 mm (with change motor on MFA)

Machine

- Constant workpiece projection from the chain track: 35 mm + edge thickness

- Max. cutting cross-section 520 mm²

- Passage width: min. 65 mm (with 35 mm projection)

- min. workpiece length in feed direction: 150 mm

- Basic height (top edge of chain track): 940 mm

- Aggregate side: Left in feed direction

- Pneumatic connection: approx. 7 - 8 bar

Release agent specification top/bottom

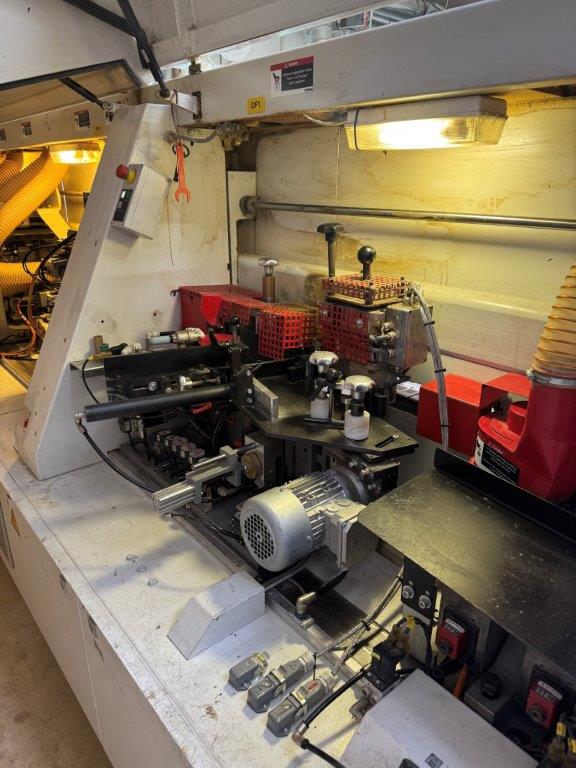

Joining unit 08.379 and blow nozzle

- with 2 motors 4 kW each, 9000 rpm, 150 Hz

Gluing unit 283.1513 with oil bath gearbox

- Glue dispenser 0.8 l 60 mm high with quick-lock system

- can be used for hot melt or PU glue

- with single roller/ strip magazine, roller diameter 800 mm

- with 3 main pressure rollers and 3 pressure rollers

Cutting unit 08.415

- pneumatically swivels to 0° or 8

- with 2 motors 660 kW, 400 V, 200 Hz, 12000 rpm

- 2 HM cross-cut saw blades 160 x 3.5 x 22, Z=36

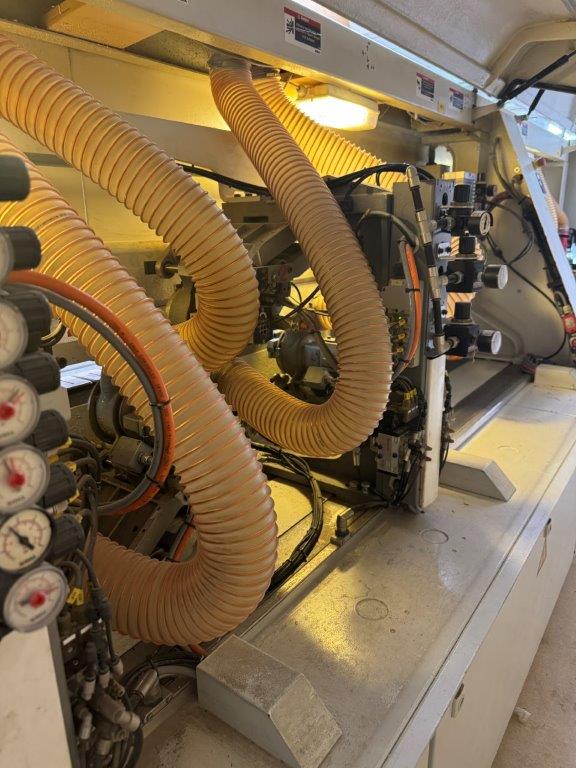

Copy trimming unit SKF-L

- with 2 motors 180 W, 400 V, 200 Hz, 12000 rpm

- and 2 motors 400 W, 400 V, 200 Hz, 12000 rpm

- 1 set of DP profile cutters I 80x12xHSK25-R, Z = 4, with HSK25 holder

- Profile length in throughfeed direction: max. approx. 50 mm

- Workpiece thickness: max. 60 mm

- Working speed: max. approx. 20 m/min

- Distance between 2 workpieces: min. approx. 400 mm

- min. workpiece projection = 35 mm + profile depth

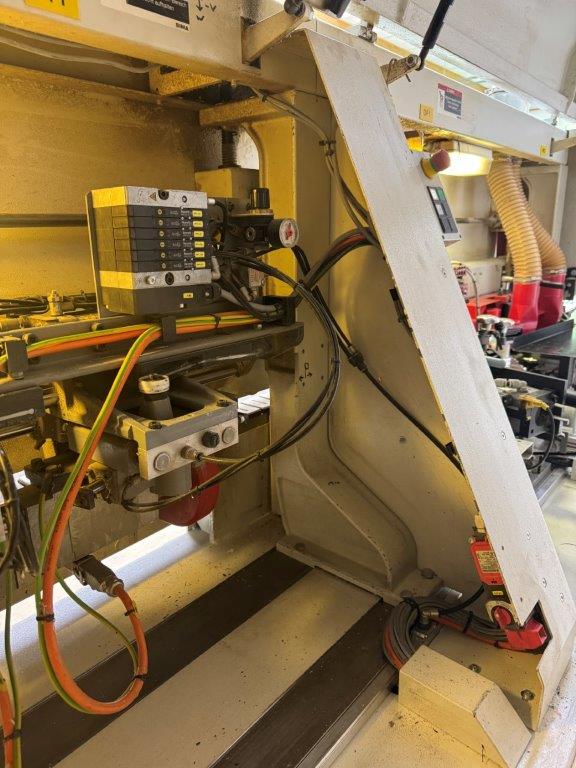

Profile scraper unit 08.519

- For rescraping an upper and lower milled quarter circle profile

Spray cleaning agent

Self-scanning scraper unit 08.521

- For removing hot melt adhesive residue from the edge area of the top and bottom of workpieces

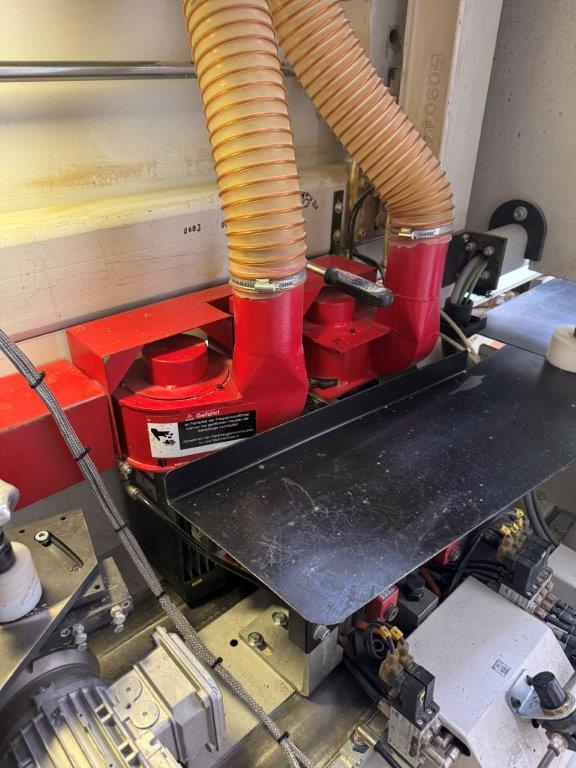

Buffing unit 08.617-2

- with an upper and lower motor: 180 W, 50 Hz, 1400 rpm

- 2 polishing wheels 50 x 160 x 19 mm

Note:

The technical data and descriptions are transcribed from the original order confirmation. The information is for reference only and is not legally binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia