Single sided edge banding machine

Brand: IMA

Type: NOVIMAT/K/I/G80/821/R3

Year: 2000

Left hand machine

Technical data:

Strip dimensions:

min. strip length at coil material: approx. 220 mm

min. strip height at coil material: approx. 14 mm

max. strip height: approx. 50 mm

max. strip thickness at coil material: approx. 3,0 mm

Workpiece dimensions:

min.workpiece length: approx. 268 mm

workpiece thickness: approx. 10-45 mm

fix workpiece overhang: approx. 38 mm

min. workpiece width at workpiece thickness up to 25mm approx. 70 mm

min. workpiece width at workpiece thickness from 25mm approx. 110 mm

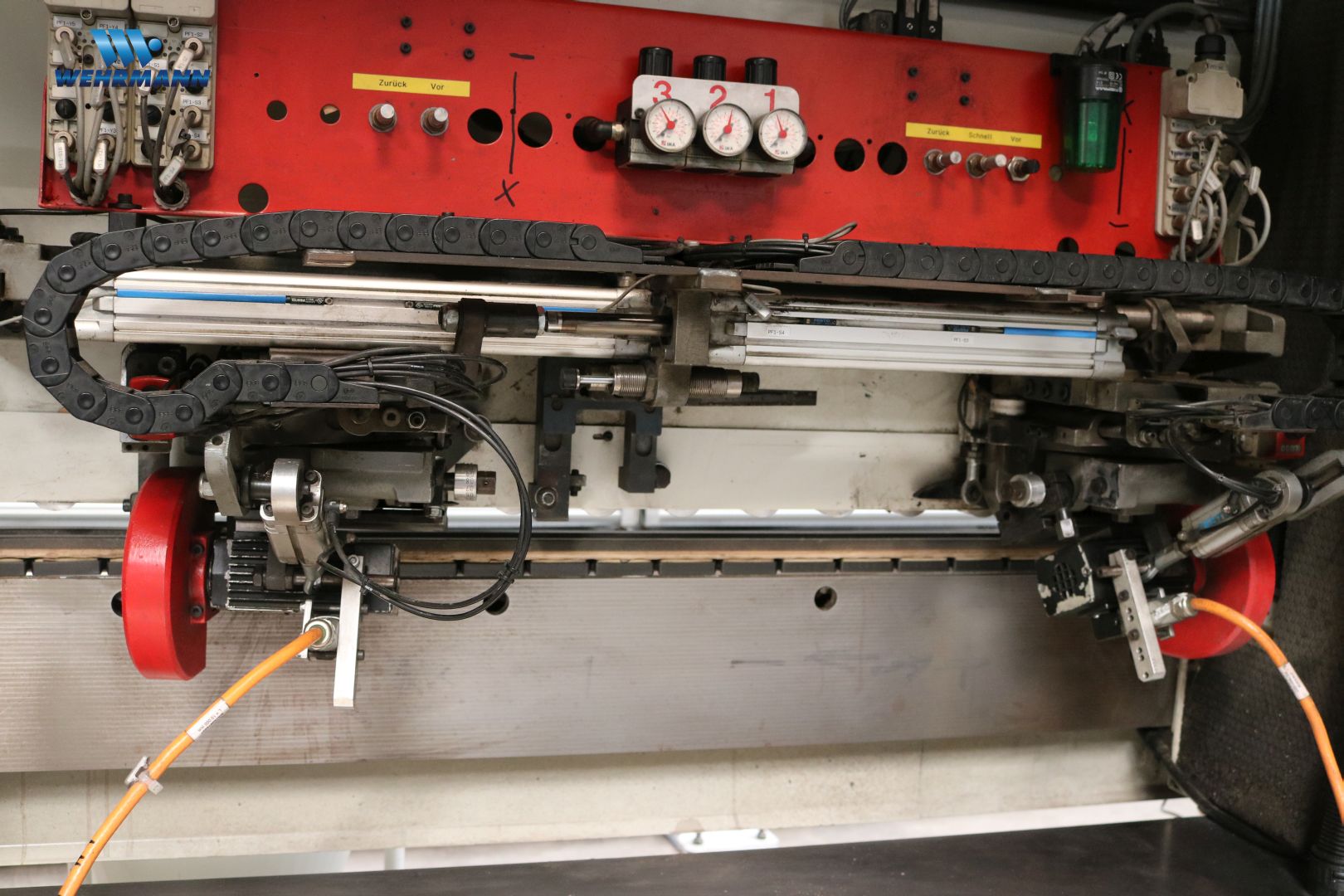

Throughfeed speed: approx. 5-25 m/min

Working height: approx. 950 mm

Unit control:

via line control-integrated in the IMATRONIC 121

Anti-stick solvent application top + bottom

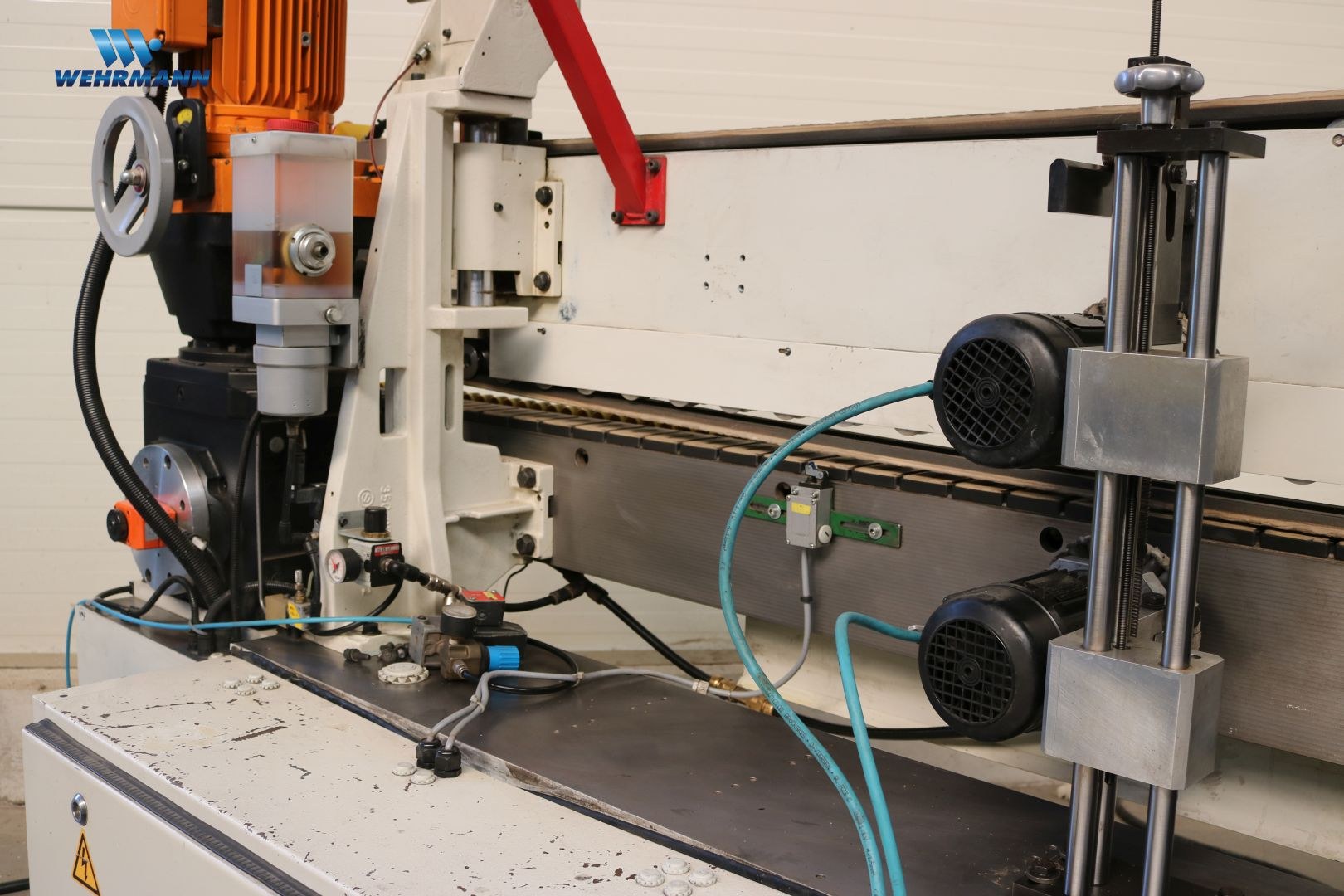

Pre-milling:

for edge re-milling calibration of formated workpieces or milling of sideway grooves,

rebating or profiling controllable and not swivable

2 motors 4,5kW 400V 150Hz 9000rpm

2xIR-heater approx.300mm long /1,5kW

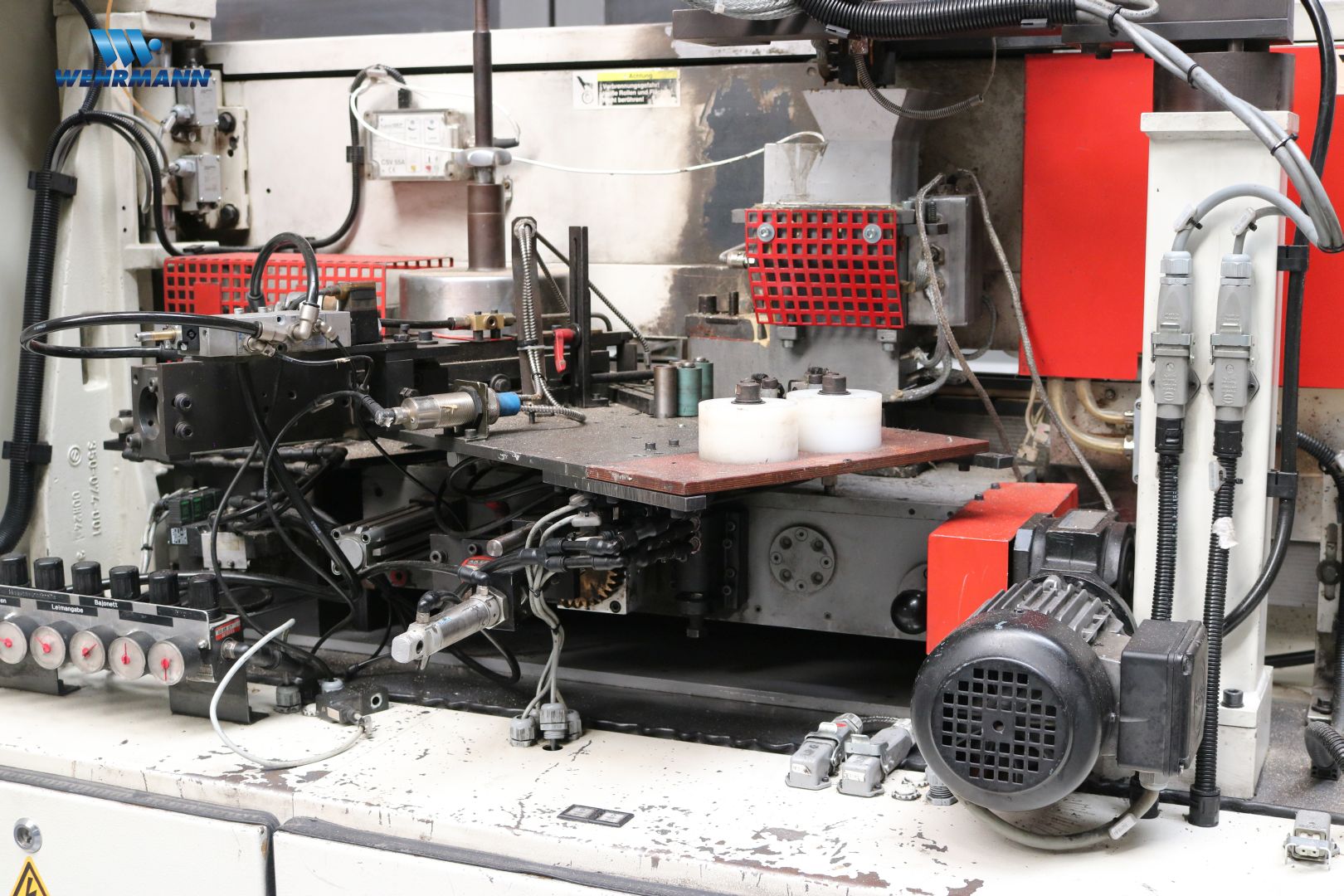

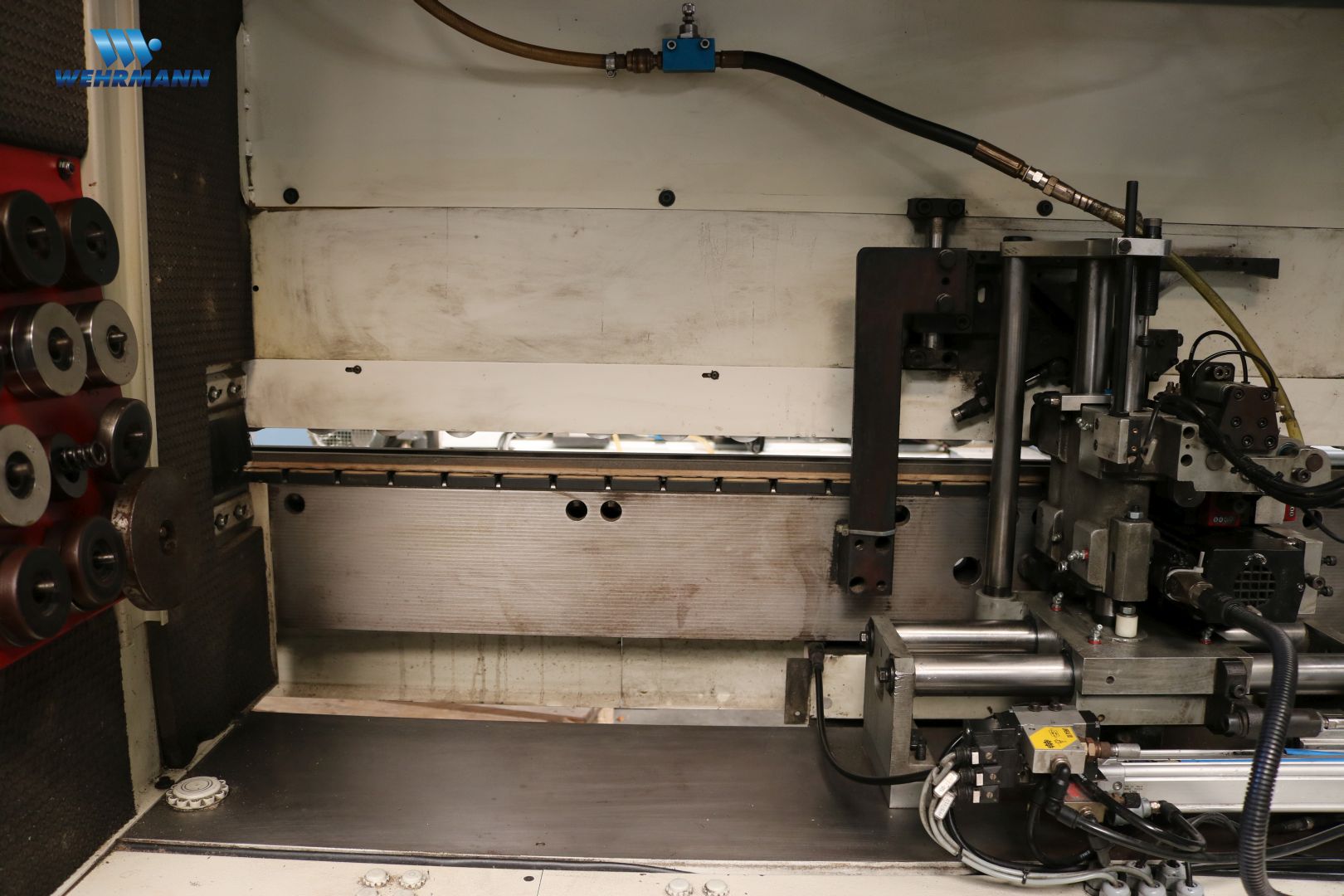

Gluing unit with quick lock

4-fold pressure zone up to 3mm,

pneum. pressure, moveable

End trimming unit:

flush or with chamfer

2 motors 200W

horizontal manual swivable 0-25°

side tracing

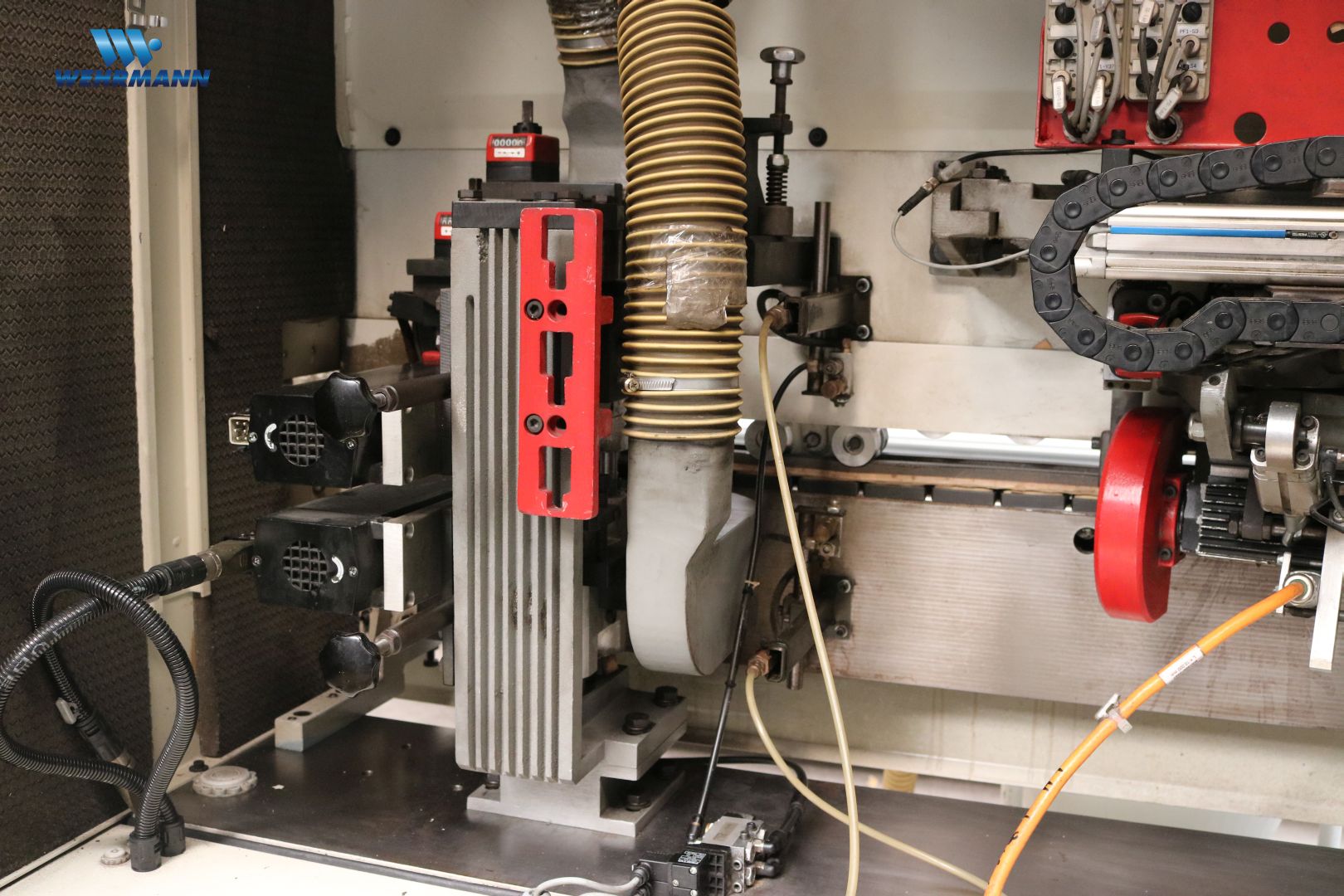

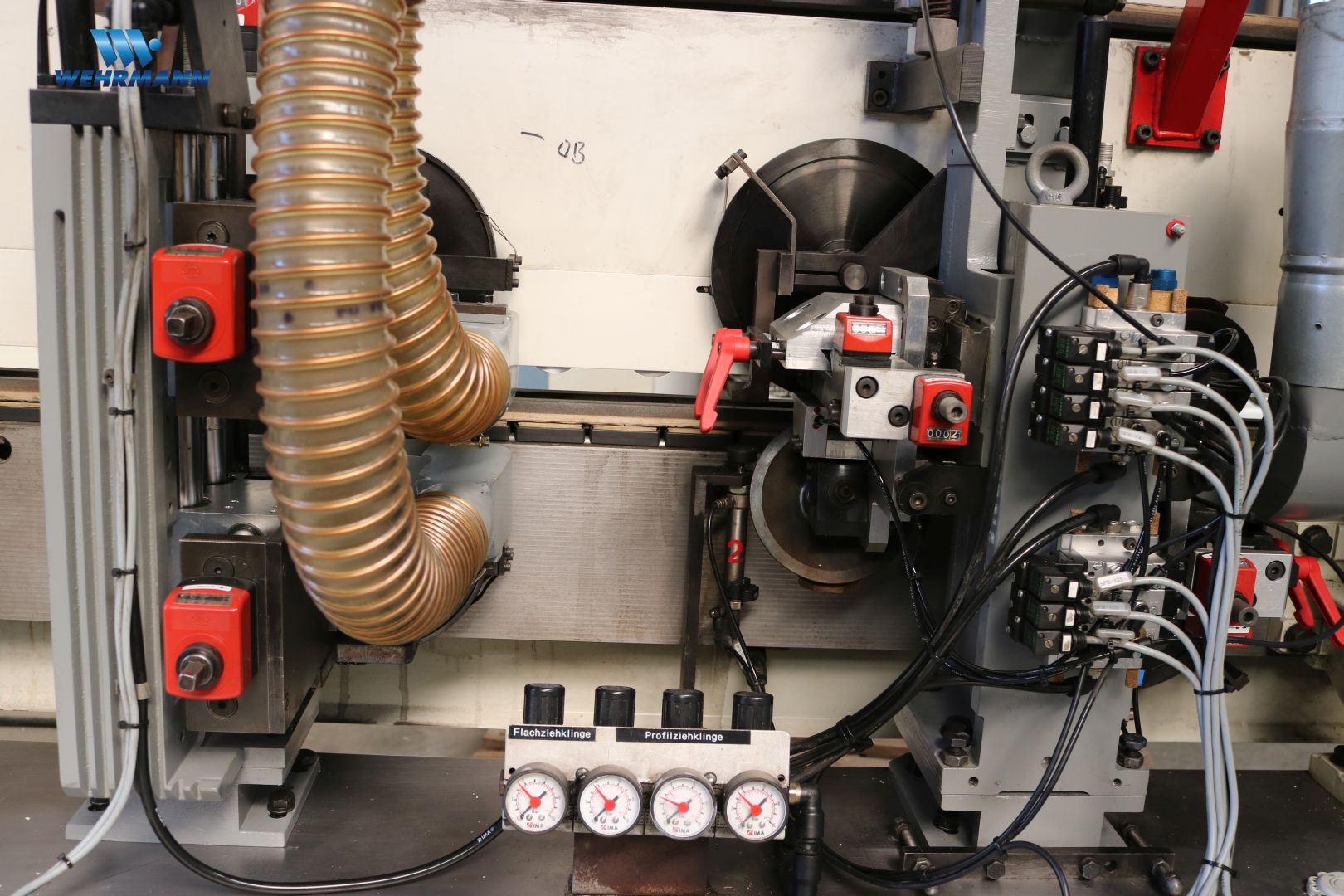

Milling unit:

max. 3° swivable

with height tracing

2x Motors 1,0kW

Multi processing unit

for fine/profile milling of the upper+lower length, frontal and rear edge

with height tracing and side tracing

2 Motors 660W/400V

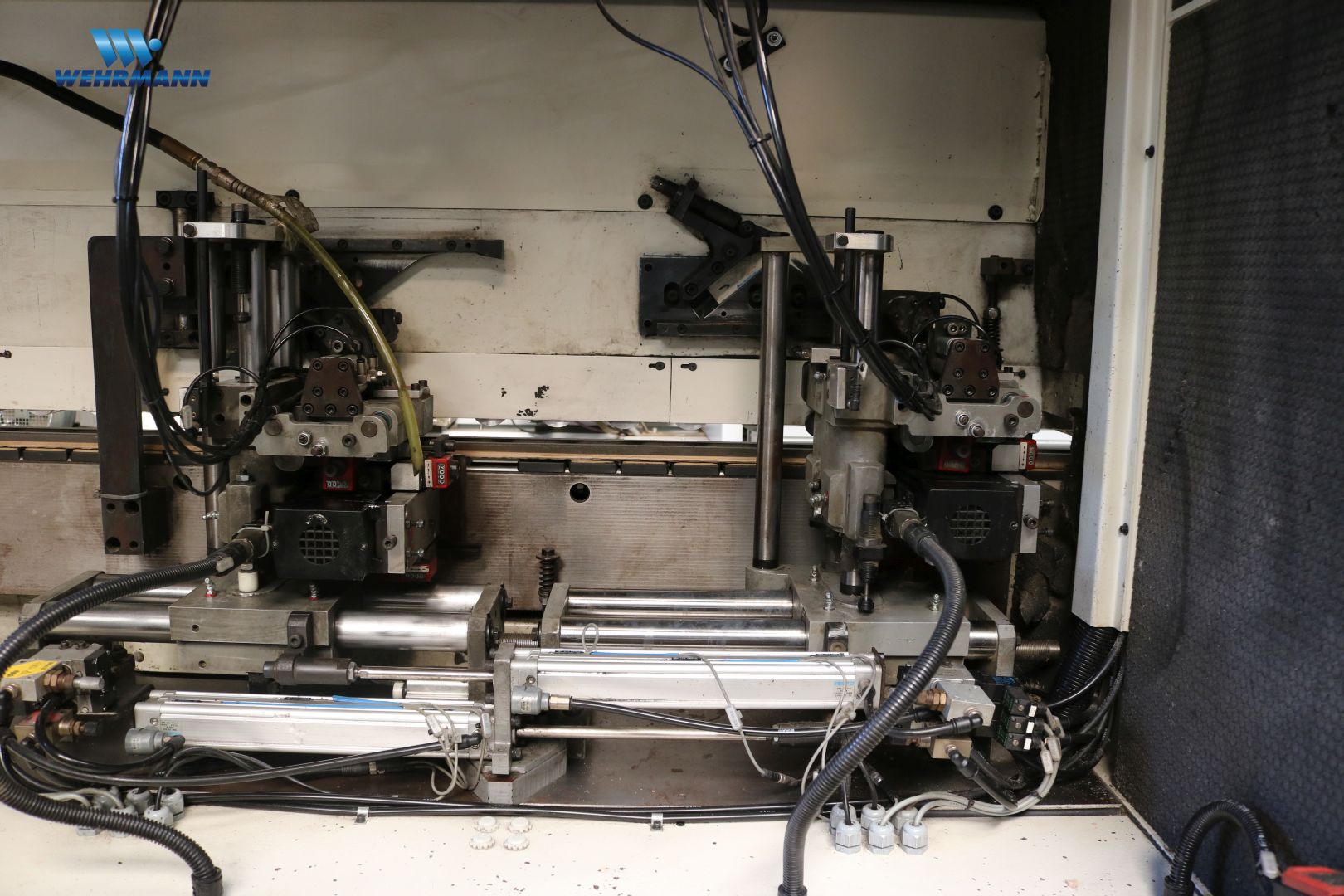

Profile scraping unit:

for scraping of the uppper and lower profiles

with height tracing and sideway tracing

Flat scraper top+bottom

Buffing unit

for cleaning top+bottom

2x Motor 0,25kW

Free place for groove milling unit

Note:

The specifications and descriptions are a copy of the order confirmation at that time. Data are for information and are not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia