BrandIMA

typeCombima/II/390/B/L12

stateUsed

stock number0401854

year2010

- Release agent application top and bottom

- Scoring saw with 2.2 kW motor

- Rough trimming unit with 8.0 kW motor

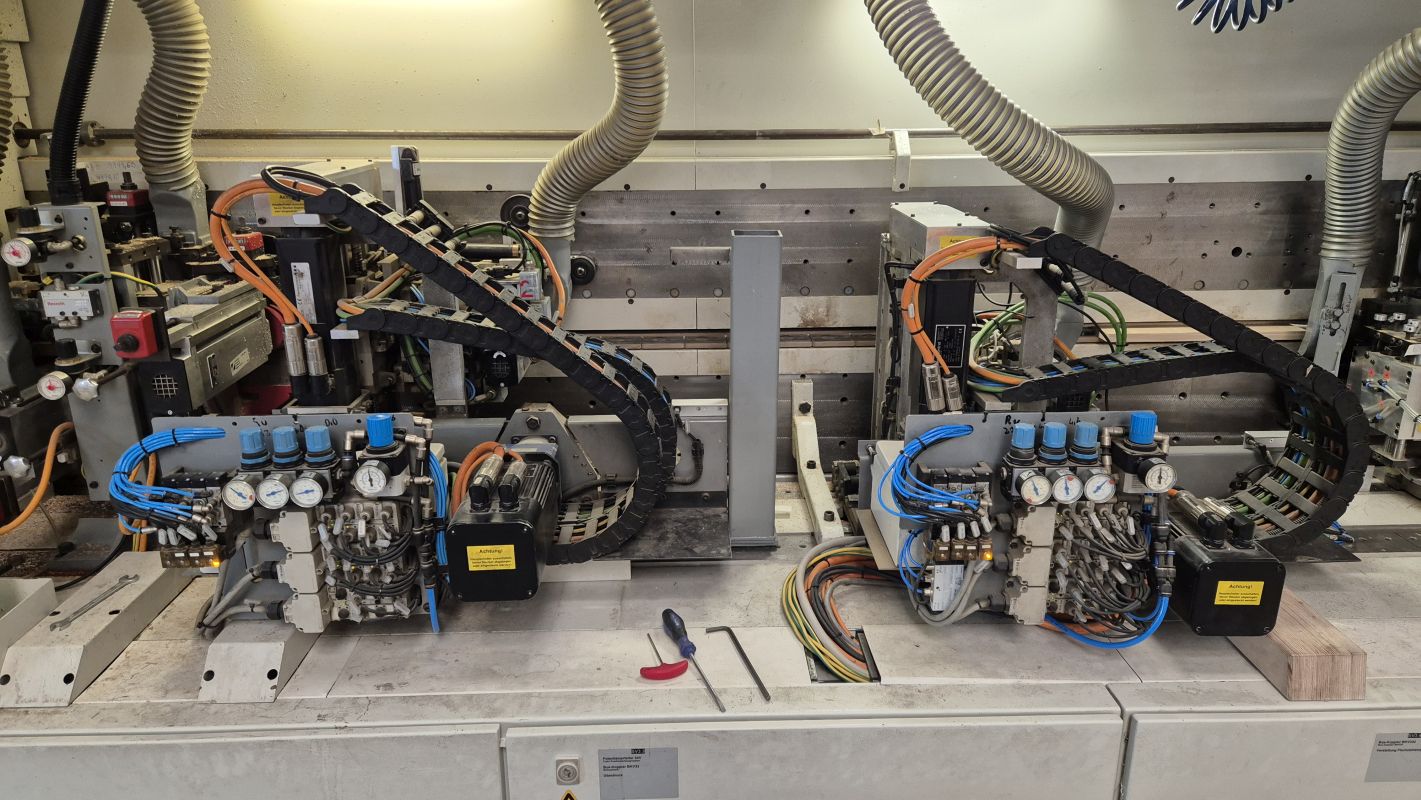

- Double milling unit with 2 motors, each 4.5 kW

- Gluing unit for hot-melt adhesive

- End trimming unit

- Flush milling unit

- Multifunction unit

- Multi-profile scraper unit

- Spray nozzles top and bottom

- Flat scraper unit

- Buffing unit

- Grooving unit

Questions about this machine

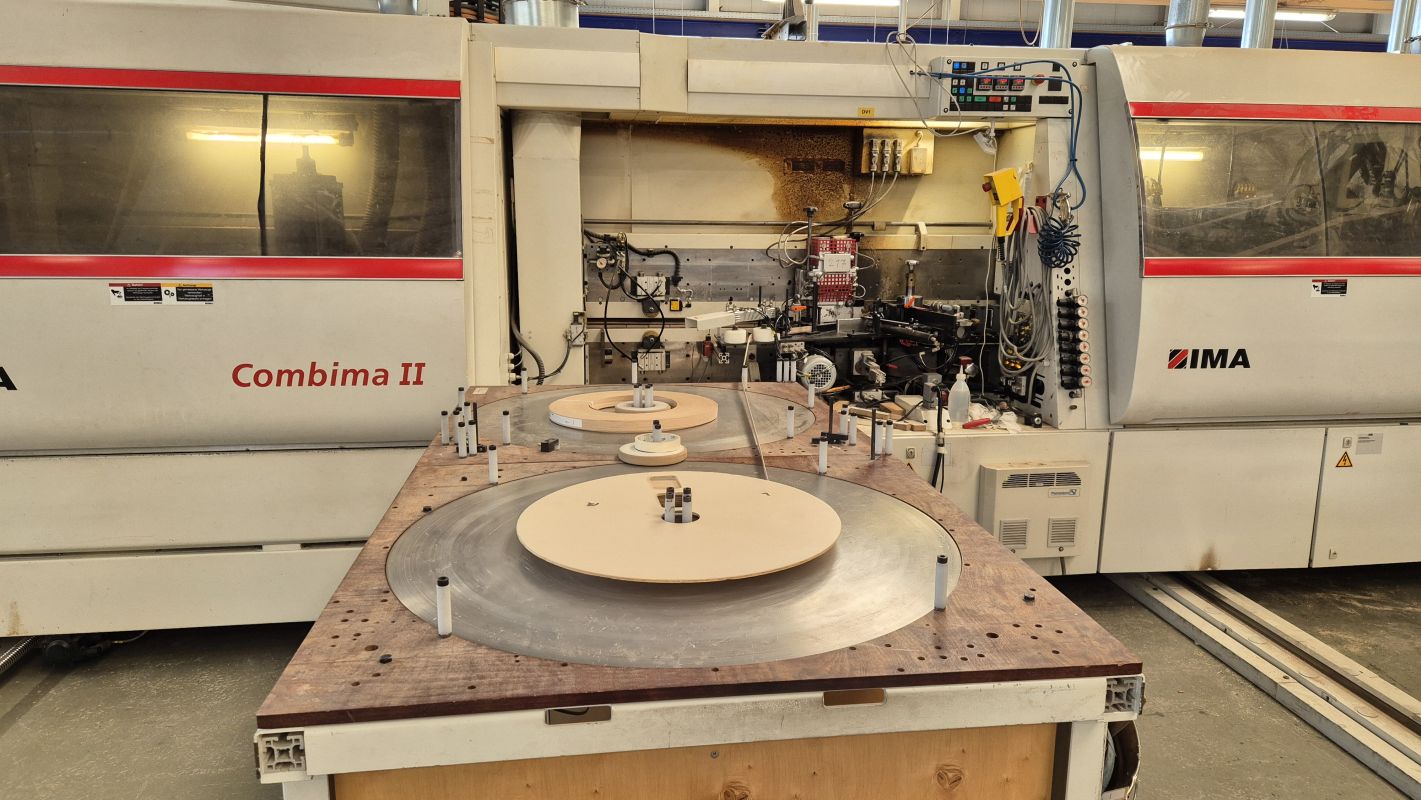

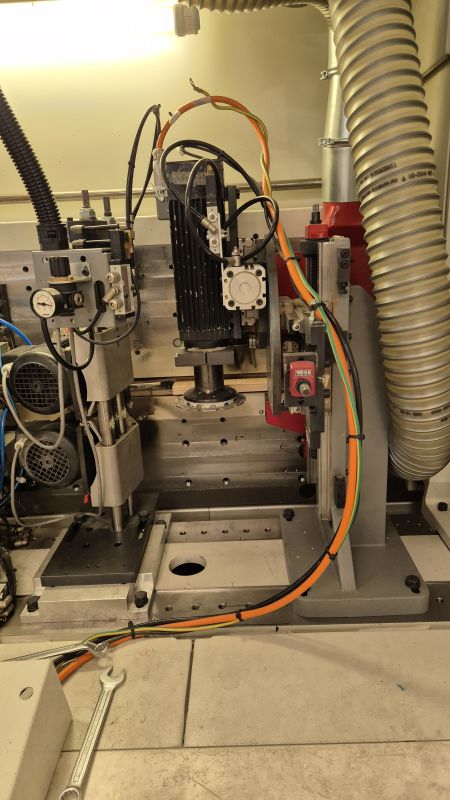

double - sided edge banding machine

Brand: IMA

Type: Combima/II/390/B/L12

Year of manufacture: 2010

For longitudinal and cross feed

- 2 low-maintenance precision roller chains with 75 mm wide and 85 mm long, rubber-coated chain plates.

- With dogs - spacing 1080 mm. Pneumatically adjustable to heights of 8, 16, or 24 mm.

ICOS OPEN Control System

Max. feed width: 3,300 mm

Program-controlled master + slave width adjustment

Fixed reference side on the left in feed direction

Workpiece dimensions:

Min. feed width: 244 mm (in longitudinal processing)

Max. workpiece width (with chain conveyor extension): 1,300 mm

Min. workpiece thickness: 8 mm

Max. workpiece thickness: 45 mm (with copying function) / 60 mm (without copying)

Edgebanding material:

Min. height: 14 mm, max. height: 65 mm

Roll material: min. thickness 0.3 mm, max. thickness 3 mm

Strips and lippings:

Min. thickness: 0.8 mm, max. thickness: 12 mm

Feed speed: 10 - 50 m/min, with frequency-controlled drive

Infeed device:

With 5 skewed, powered rollers acting from above

Center support with roller conveyor, automatically lowerable and self-centering

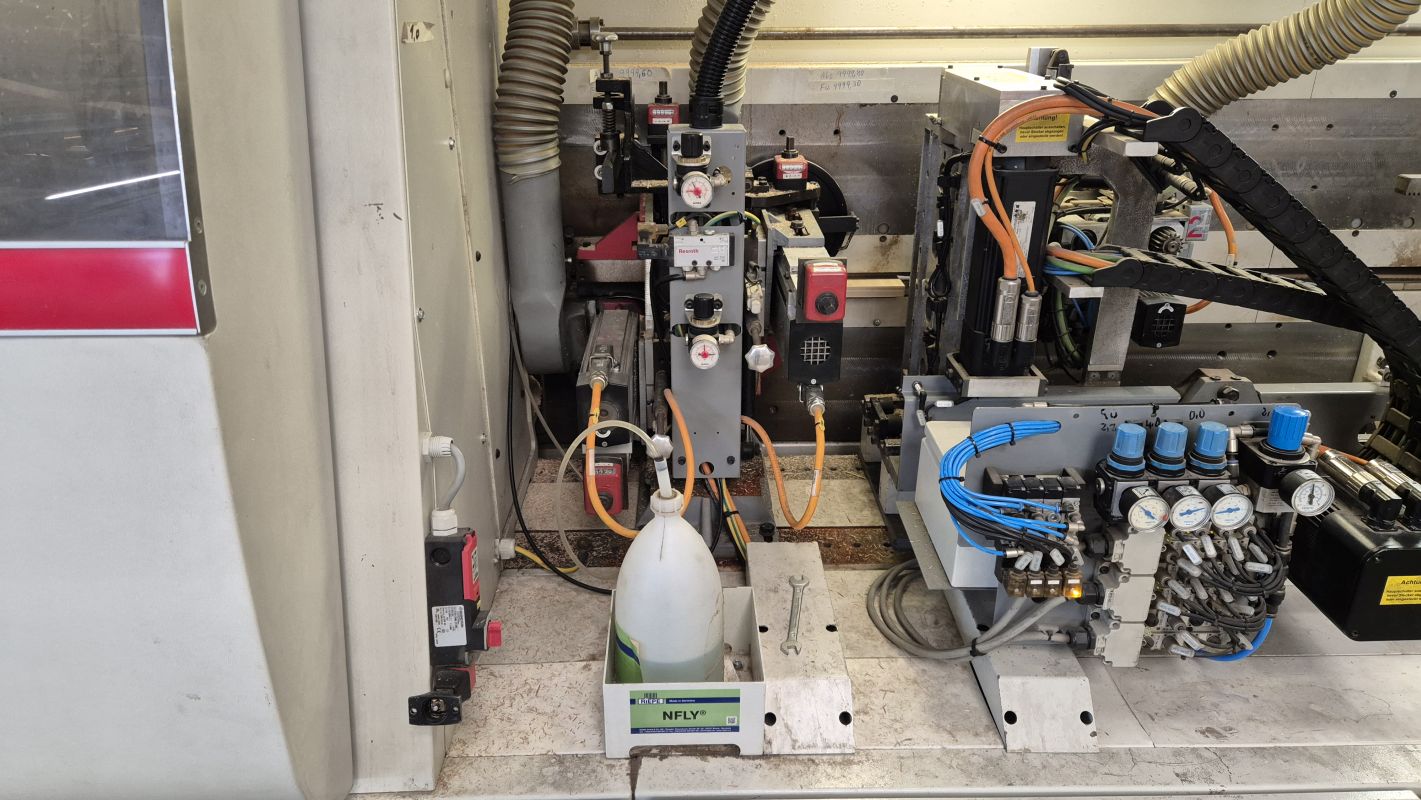

Per side equipped with:

Release agent application top and bottom

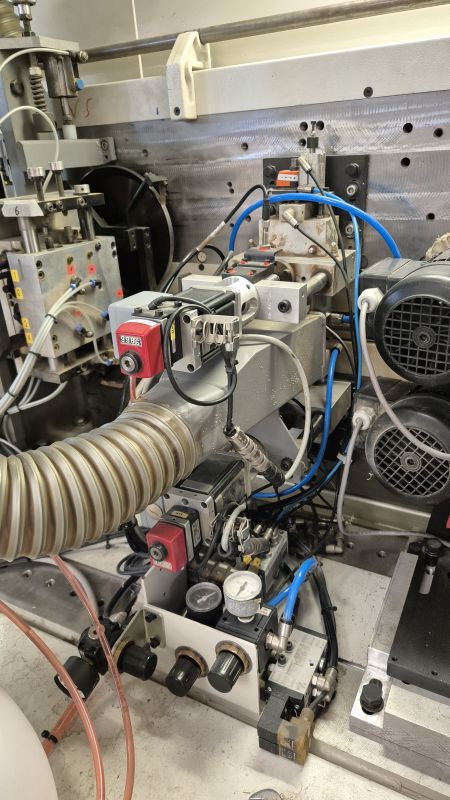

Scoring saw with 2.2 kW motor, 100 Hz, 6,000 rpm, pneumatically controlled

Electronic positioning for stepless horizontal adjustment

Vertical adjustment manual with mechanical display

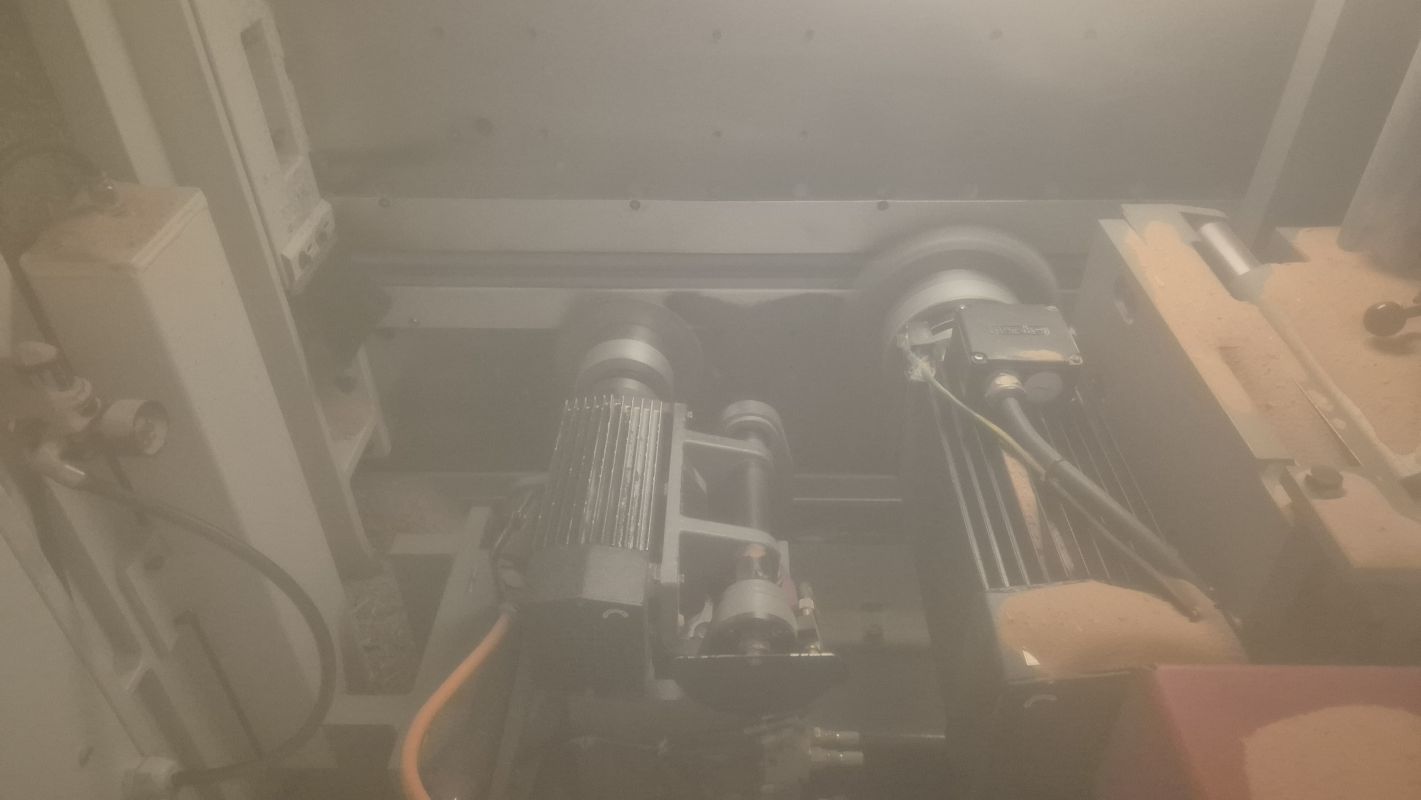

Rough trimming unit with 8.0 kW motor, 100 Hz, 6,000 rpm

Electronic positioning for stepless horizontal adjustment

Double milling unit with 2 motors, each 4.5 kW, 150 Hz, 9,000 rpm

Electronic positioning for stepless horizontal adjustment

Vertical adjustment manual with mechanical display

Gluing unit for hot-melt adhesive

With single roll/strip magazine for roll material up to 3 mm and strips up to 12 mm

Double roll magazine for roll material up to 3 mm (attachable to single roll magazine)

Horizontal roll holder

End trimming unit

Mounted on top pressure beam, with 2 motors, each 660 W, 200 Hz

Pneumatic swiveling 0° + 25° for straight and bevel trimming cuts

Automatic adjustment for bevel trimming with two different edge thicknesses (e.g. 0.4 and 1.2 mm), as well as for “edge overhang” copying with edge thickness 1.0 - 3.0 mm

Automatic adaptation to feed speed 20 + 30 m/min

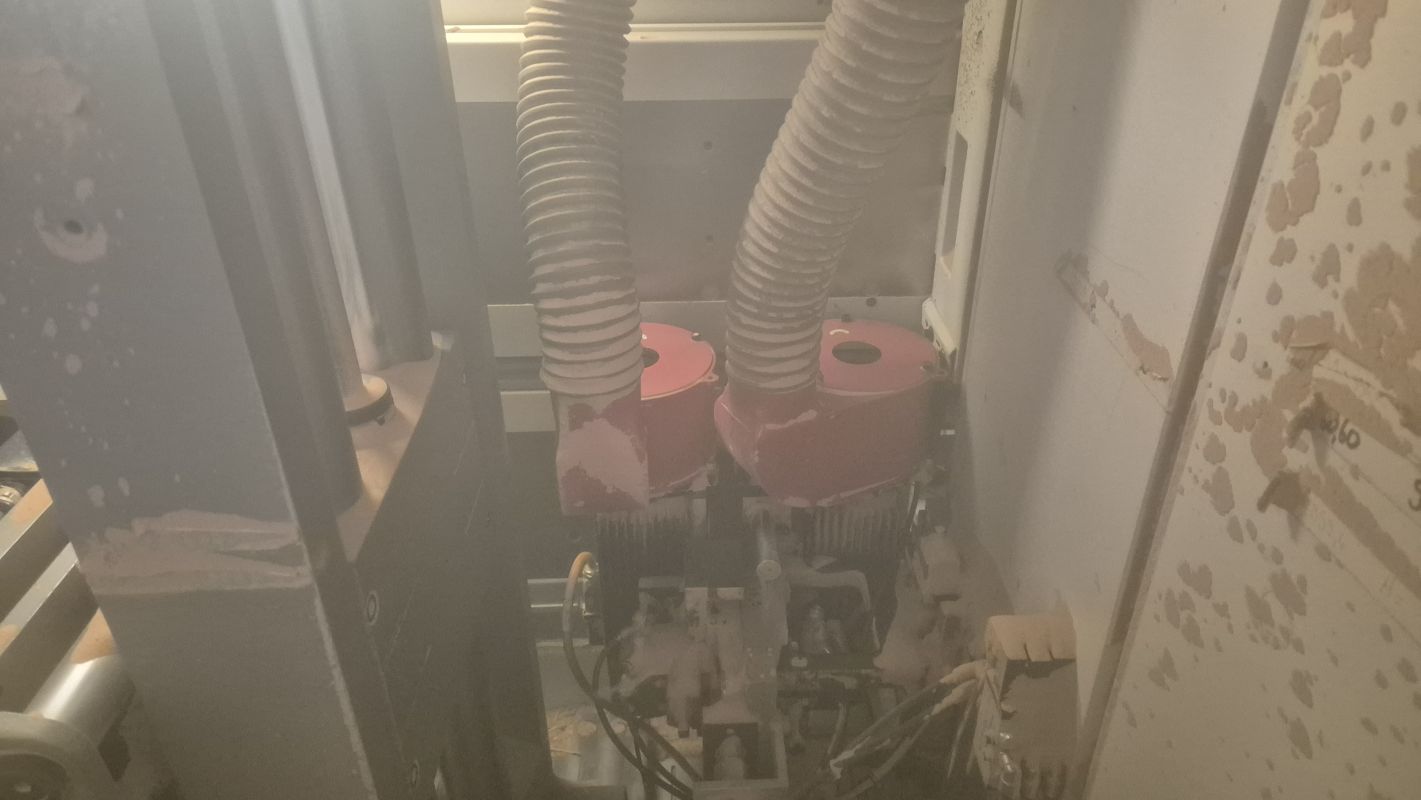

Flush milling unit 08.0555

With 2 motors, 1,850 W, 200 Hz, 12,000 rpm

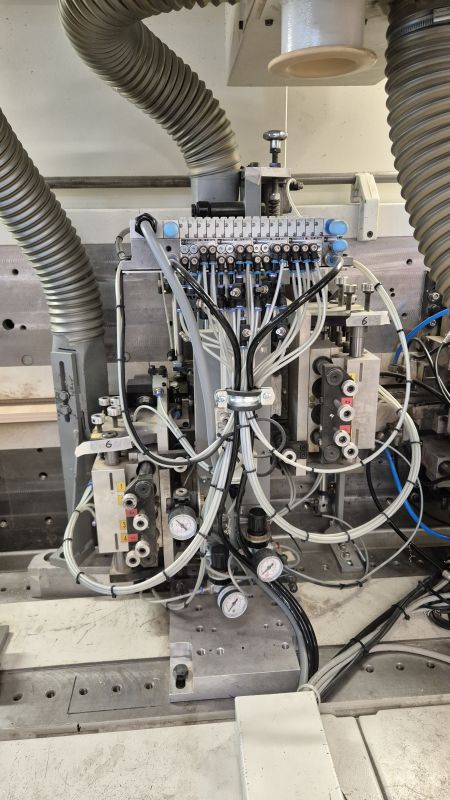

Multifunction unit 08.353

NC-controlled, with 2 motors, automatic tooling for 4 profiles

Multi-profile scraper unit

With automatic tooling for 4 profiles via fixed-point control

Spray nozzles top and bottom

For applying cleaning agents

Flat scraper unit

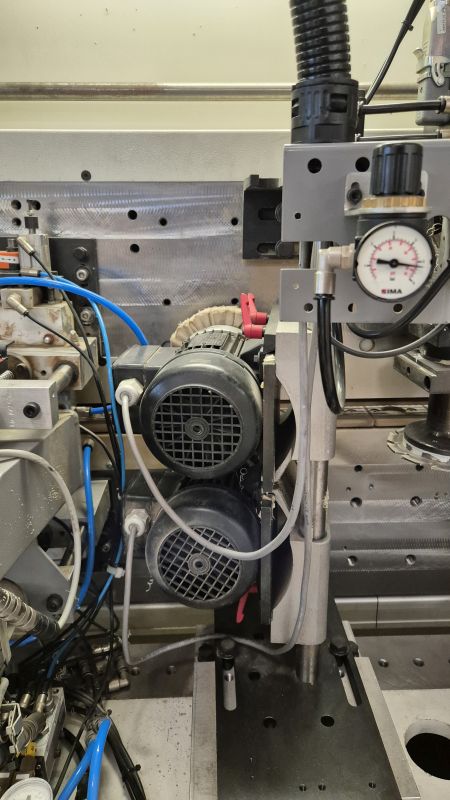

Buffing unit

With 2 motors, each 180 W, 50 Hz, 1,400 rpm

1 Grooving unit

With 4.5 kW motor, 150 Hz, 9,000 rpm

Horizontally and vertically manually adjustable with mechanical digital display

Pneumatic activation control

Manual swiveling 90°

ICOS OPEN

PC-based control system with integrated PLC and electronic path control

User-friendly interface with Windows standards

Simple, component-oriented program creation

Freely definable program names

Note:

The technical data and descriptions are copies of the order confirmation at the time. Data is for information purposes only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia