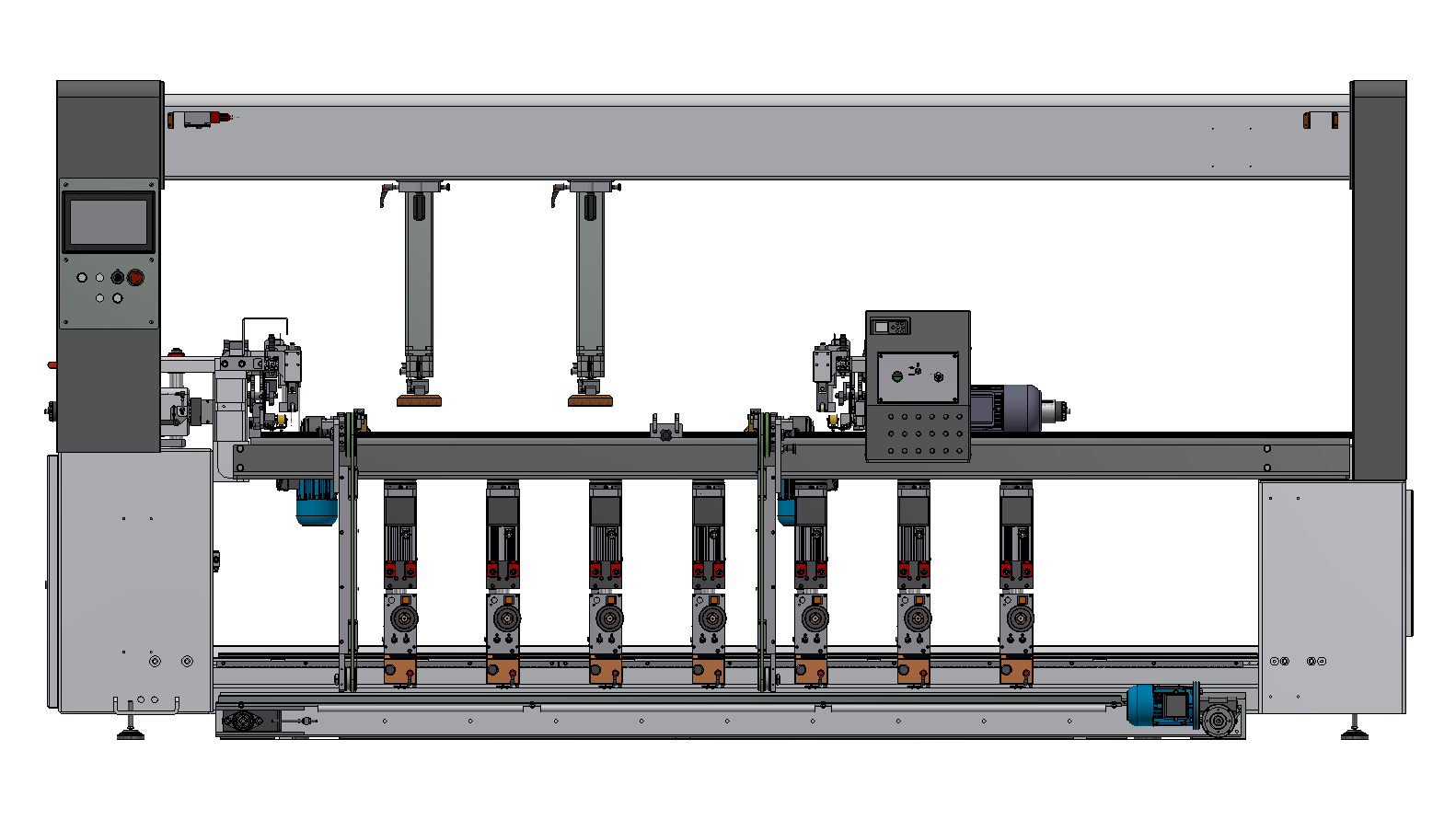

BrandVITAP

typeSIGMA B1

stateNew

stock number1110127

- 2800 mm working table

- PLC and touch screen

- 2 horizontal boring heads with 21 spindles each prepared for quick chucks

- 2 CN programable stops

Questions about this machine

autom. boring machine

Brand: VITAP

Type: SIGMA B1

New machine

technical detail:

- 2800 mm working table

- PLC and touch screen

- 2 horizontal boring heads with 21 spindles each prepared for quick chucks

- 2 motors each 1,5 kW

- the right horizontal boring head is movable with the possibility to pass over the vertical boring groups and fitted on prismatic guide with ball bushes and electronic digital indicator.

- Digital position indicators for height regulation of the horizontal boring heads

- 2 pneumatic stops

- changing horizontal/vertical drilling circuit

- Belt conveyors fitted on springs sliding on prismatic guide with ball bushes

- Front and side pneumatic pushers

- Security on line circuit

- 700 mm Infeed conveyor

- Horizontal movement of the right head by ball bushes guide with electronic digital

indicator

- Standard accessories

- CE standards

Dust and chips collecting device 2800 mms compulsory for CEE countries.

Perimeter security bar with photocell compulsory for CEE countries

Options:

Vertical boring group complete with:

- 2 motors HP 1,5 (Kw 1,1), sliding on a guide and arranged in advance for the fitting of turnable split heads;

- The transverse displacement of the motors and the rotation of the split heads are pneumatically locked by means of a selector which is situated in front of the boring group;

- The motors can be moved by means of a handle reading the measure on a digital indicator.

- The boring group is equipped with drilling depth regulation;

- The longitudinal displacement of the boring group is obtained by ball bushes with electronic digital indicator with magnetic strip

- Oleodynamic brake

Turnable of 90 degrees split head 11 spindles prepared for quick chucks:

Turnable of 90 degrees split head 9 spindles prepared for quick chucks

Vertical clamp complete with working table bar

We advise to quote the same number of vertical boring group less

two

spindles prepared for quick chucks with cylindrical attachment diam. 10 mms

Hopper feeder for wooden strips

Software for set up of machine

Central feeding unit

Powered out feed conveyor

your contact person

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia