BrandHOMAG

typeOptimat BHX200/D

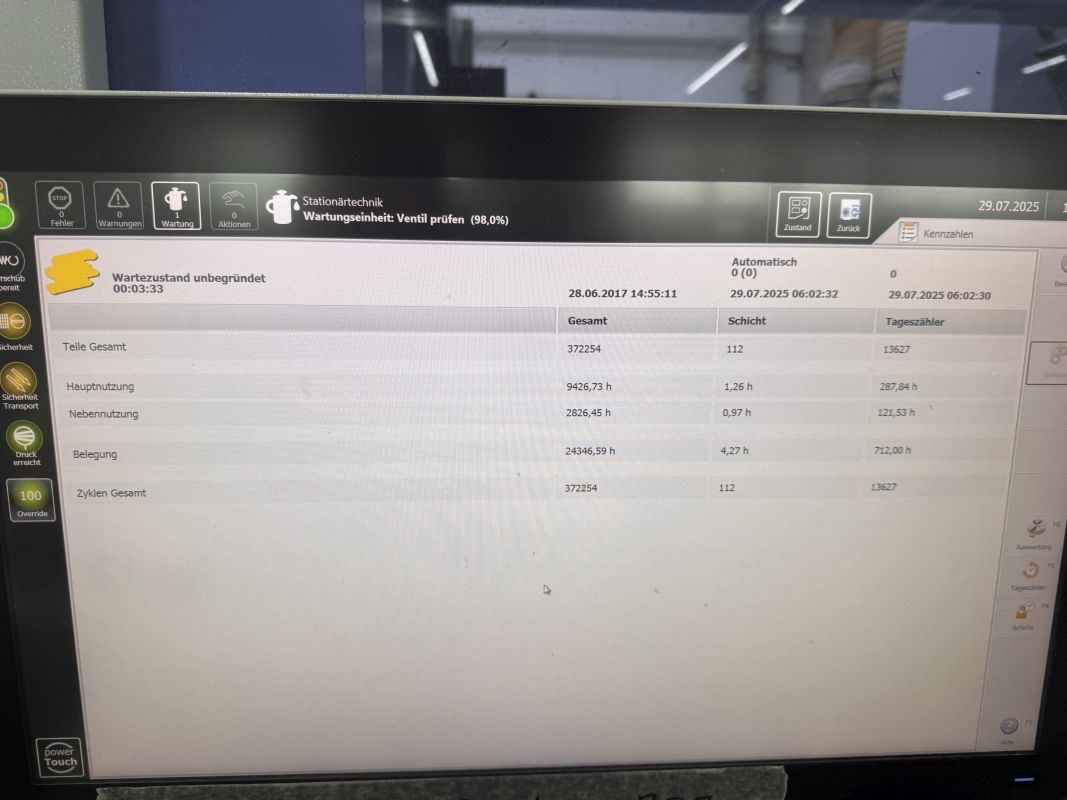

stateUsed

stock number0401835

year2017

Speed of the axes: X/Y = 50 m/min / Z = 15 m/min

Workpiece length: 200 - 3,050 mm

Workpiece width: 50 - 1250 mm

Workpiece thickness: 8 - 80 mm

Transport speed: up to 25 m/min

Questions about this machine

Vertical CNC machining center

Brand: Homag

Type: Optimat BHX200/D

Year of manufacture: 2017

Technical data

Speed of the axes: X/Y = 50 m/min / Z = 15 m/min

Workpiece length: 200 - 3,050 mm

Workpiece width: 50 - 1250 mm

Workpiece thickness: 8 - 80 mm

Transport speed: up to 25 m/min

Drilling gear V15 High Speed

Feed stroke Z-direction: 60 mm

Drilling depth: max. 38 mm

Direction of rotation: right/left

Speed: 1,500 - 1,700 1/min, frequency-controlled

Drive: 2.3 kW

Horizontal drilling gear with 6 spindles X-direction

6 drilling spindles: 32 mm pitch, 3 each in X - direction

Drilling depth: max. 38 mm

Drilling height Z - direction: 32 mm from top edge of workpiece

Direction of rotation: right/left

Speed: 1,500 - 1,700 1/min, frequency-controlled

Spindle type: individually controllable

Horizontal drilling gear with 4 spindles Y - direction

4 drilling spindles: 32 mm pitch, 2 each in Y - direction

Drilling depth: max. 38 mm

Drilling height Y - direction: 32 mm from top edge of workpiece

Direction of rotation: right/left

Speed: 1,500 - 1,700 1/min, frequency-controlled

Spindle type: individually controllable

Vertical fitting drilling gear, 3 spindles

Number of spindles: 3

Feed stroke Z-direction: 60 mm

Drilling depth: max. 38 mm

Spindle distance: 45 x 9.5 mm

Tool holder: 10 mm shank diameter with clamping surface

Tool projection: max. 50 mm

Tool length: max. 70 mm

Speed: max 3,000 1/min

Direction of rotation: right/left

Automatic 90° tilting grooving saw

Grooving saw unit can be tilted 90° for processing in the X-Y direction

Cutting depth: 30 mm

Cutting cross-section: max. 70 mm2

Speed: 1,500 - 7,500 rpm, frequency-controlled

Tool diameter: 125 mm

Saw blade thickness: max. 5 mm

Dowel insertion station (white glue)

consisting of:

- 2 dowel insertion tools incl. injection nozzle and dowel separator mounted on the outside of the upper processing support

- Low-pressure glue pump (double diaphragm pump 1:1 (6 bar)) incl. filter unit, low-noise, compact with low energy consumption

- 2 glue flow monitors for the glue feed valves

- 2 oil mist nozzles and 2 cleaning brushes for cleaning the glue nozzles

- 1 feed unit for glue unit

- 1 vibrating conveyor for standard dowels 8 x 35 mm or 8 x 40 mm

- 1 Filling quantity monitor for the vibratory feeder

Note: Dowel lengths of < 35 mm are not recommended due to low pull-out force.

Plausibility check (X/Y) for vertical machining centers

Tool change spindle incl. converter 10 kW (HSK63)

Tool holder: HSK63

Tool infeed: automatic

Tool diameter: max. 60 mm

Tool clamping length: max. 100 mm (175 mm from tool holder contact surface to lower edge of tool)

Tool weight: max. 5 kg incl. holder

Direction of rotation: right/left

Speed: 1,500 - 24,000 rpm, infinitely programmable

Drive: frequency-controlled three-phase current

Max. power at the tool: up to 8.5 / 10 kW in continuous / intermittent operation (S1/S6-50 %)

Spindle lubrication: Grease, permanently lubricated

Cooling: Air

Extraction: Central

4-position pick-up changer on the side for HSK63

Magazine positions: 4 tool positions

Tool holder: for HSK63

Tool weight: max. 5 kg total weight incl. HSK holder

Tool diameter: max. 60 mm

Tool clamping length: max. 100 mm

Tool change time: max. 12 - 16 sec.

1 x stop cylinder for workpiece positioning

BHX 200 workpiece clamping system

2 workpiece clamps can be moved in X direction via toothed racks.

Powercontrol with Powertouch

Powercontrol software BHX 050-200

Woodwop

Note:

The technical data and descriptions are a copy of the order confirmation at the time. Data is for information only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia