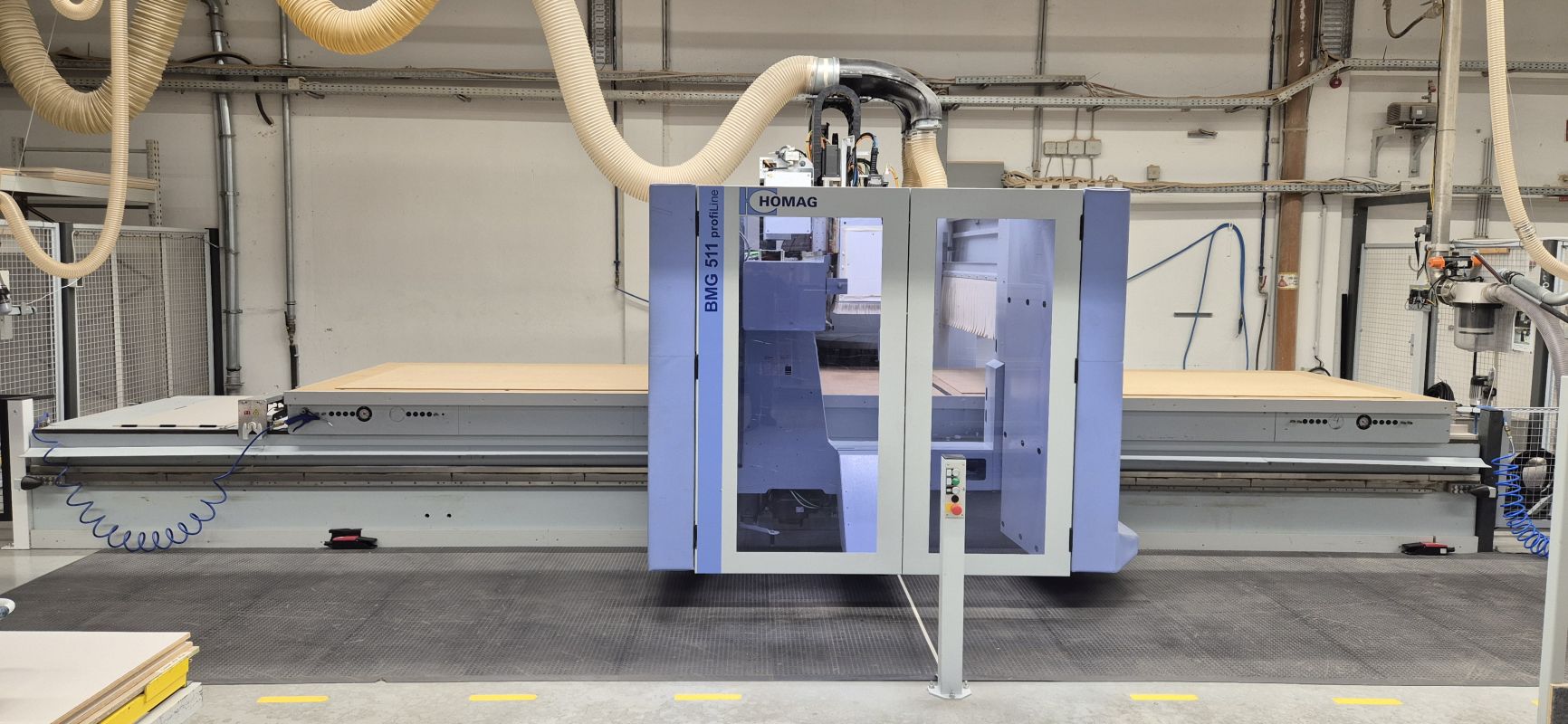

BrandHOMAG

typeBMG 511/60/12/R

stateUsed

stock number0401881

year2015

- X-axis speed: 80 m/min

- 18-position tool changer

- Drilling head with 30 spindles

- Working area: 6,000 x 1,550 mm

Questions about this machine

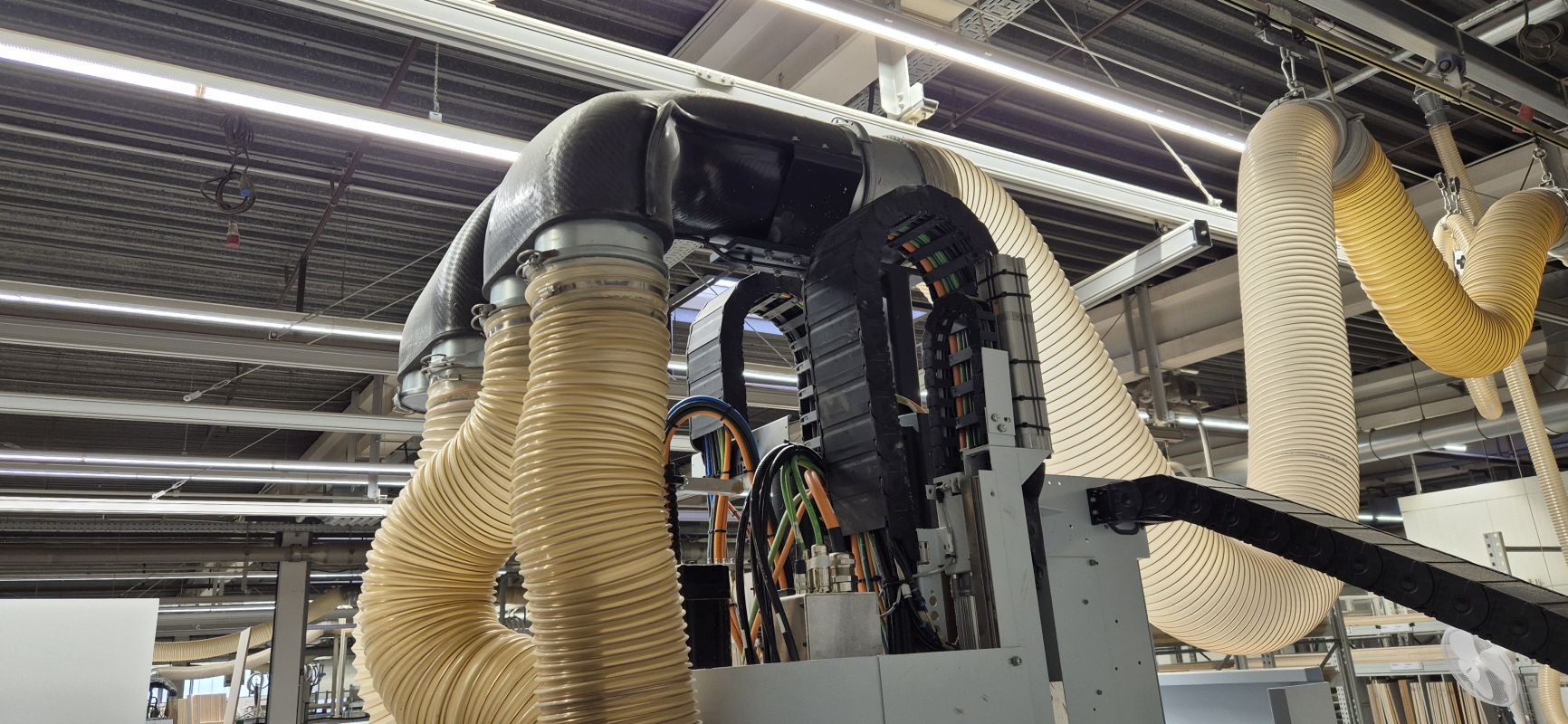

CNC - Nesting machine

Brand: Homag

Type: BMG511/60/12/R

Year of manufacture: 2015

Technical data

- X-axis speed: 80 m/min

- 18-position tool changer

- Drilling head with 30 spindles

- Working area: 6,000 x 1,550 mm

Workpiece parameters:

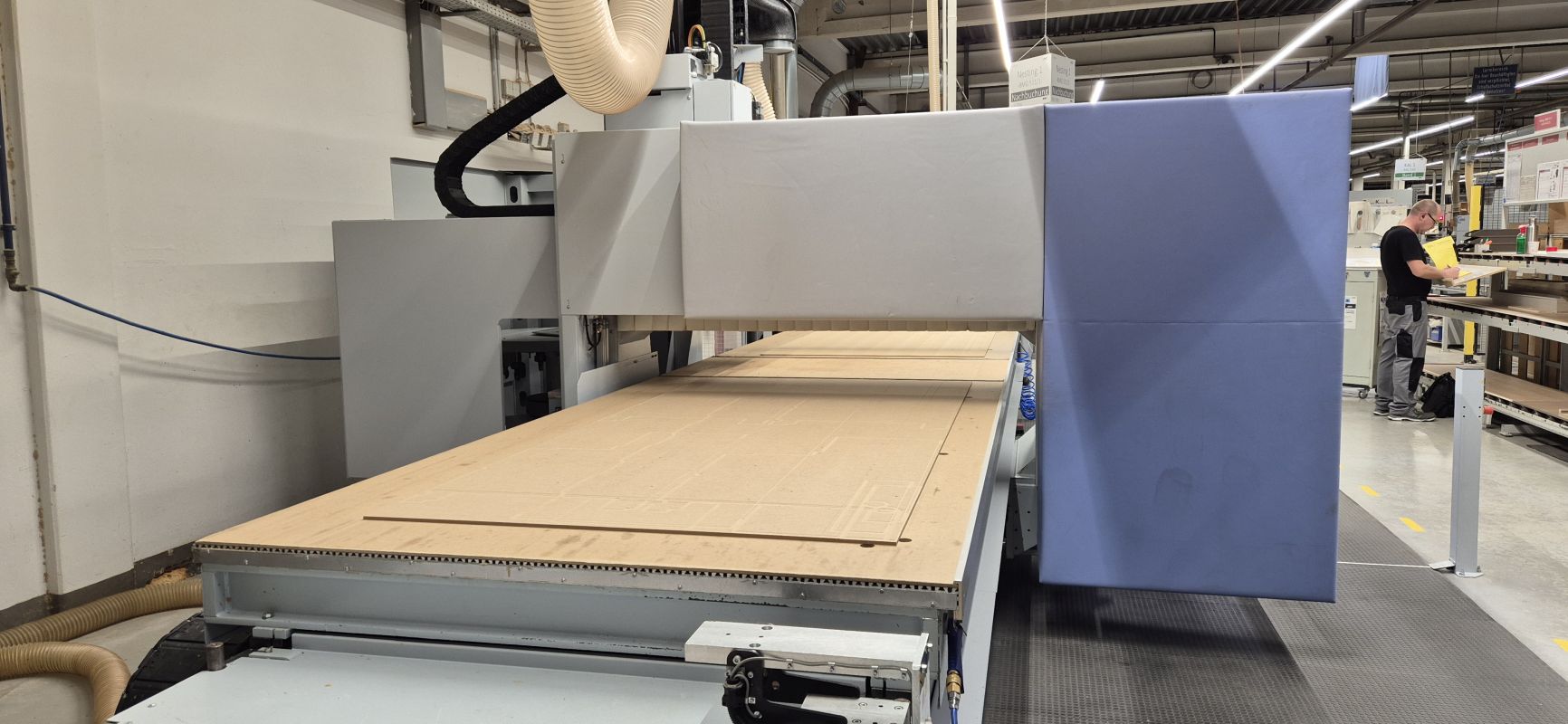

Length (single setup): 6,000 mm

Length (pendulum operation): 1,550 - 3,200 mm

Width: max. 1,550 mm (with rear stop and milling cutter Ø 25 mm)

Workpiece thickness: 275 mm including clamping devices

Up to 60 mm with standard clamping equipment

Speed Pack:

Increased maximum feed speed of X-axis to 80 m/min

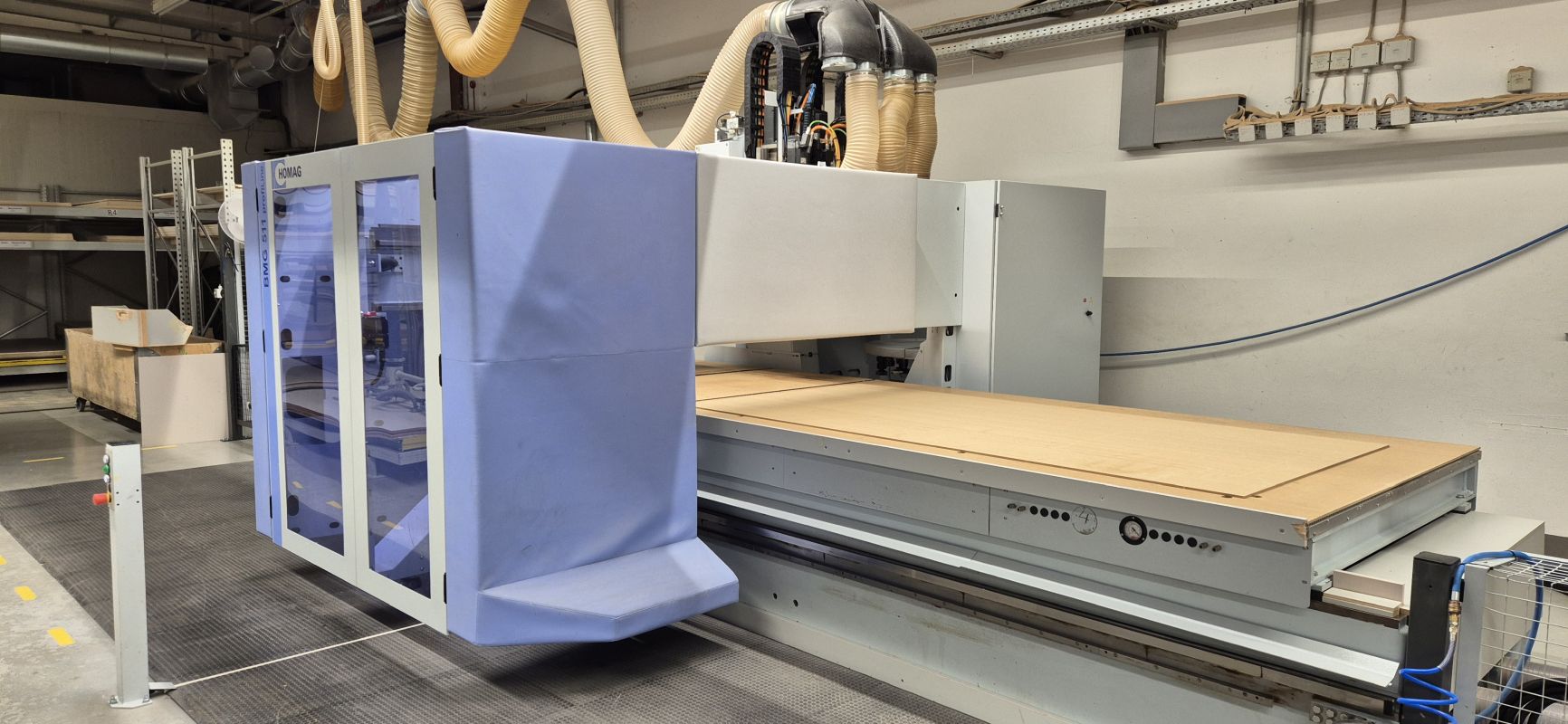

Tool transfer station:

Located on the left side of the machine bed

Disc-type tool changer:18 positions

Capacity for either

18 x 130 mm tool diameter, or

9 x 180 mm + 9 x 70 mm tools

Maximum aggregate length: 320 mm

Main milling spindle:

12 kW (S6 duty) / 9.5 kW (S1 duty)

Frequency-controlled speed: 0 - 24,000 rpm

C-axis:

With aggregate interface

Drive for all units with swiveling axis

Unlimited swivel range

Interface:

For FLEX-5 aggregate

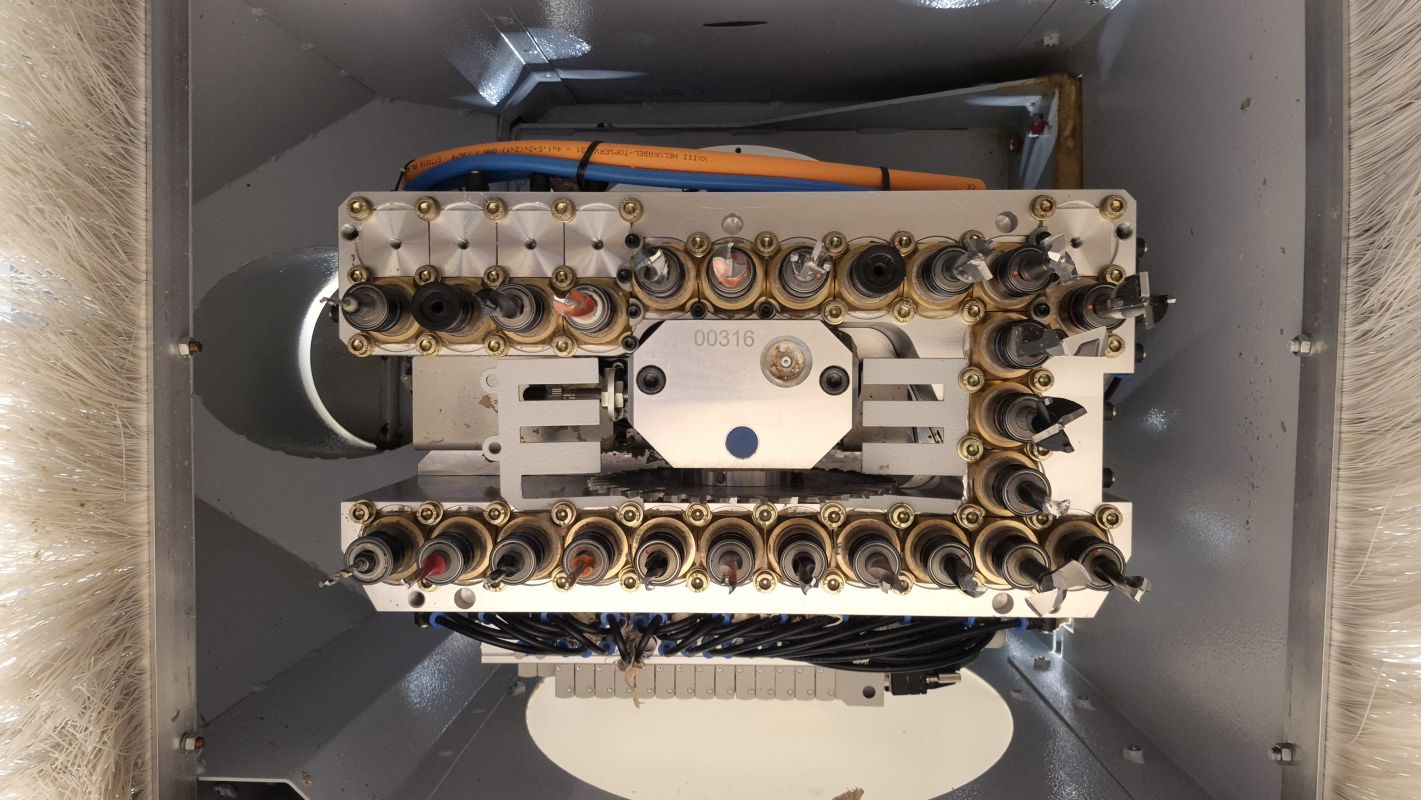

Drilling head (30 spindles):

V20 / H10 / S360° “MPU”

Multi-Processing Unit with C-axis ±185° for drilling and sawing at any angle.

20 vertical high-speed spindles, each with quick-change system

Spindle layout in U-shape:

3 rows with 11, 3, and 6 spindles, spacing 32 mm

10 horizontal spindles:

4 spindle pairs at 32 mm spacing

1 spindle pair at 320 mm spacing

Grooving / Separation saw:

For saw blade diameters up to 200 mm

Base structure - Grid table:

Grid table with slotted aluminum profile

Dynamic table area allocation (R-table):

The machine automatically checks the maximum possible part dimensions based on the program configuration.

Vacuum zones are permanently assigned to machining fields.

Machine control:

POWERCONTROL PC 86 POWERTOUCH

21.5" Full HD multi-touch display

WoodWop software for graphical, dialog-based CNC programming

Vacuum system:

The machine is supplied via a customer-side vacuum system

(No integrated vacuum pump)

Note:

The technical data and descriptions are copies of the order confirmation at the time. The information is for informational purposes only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia