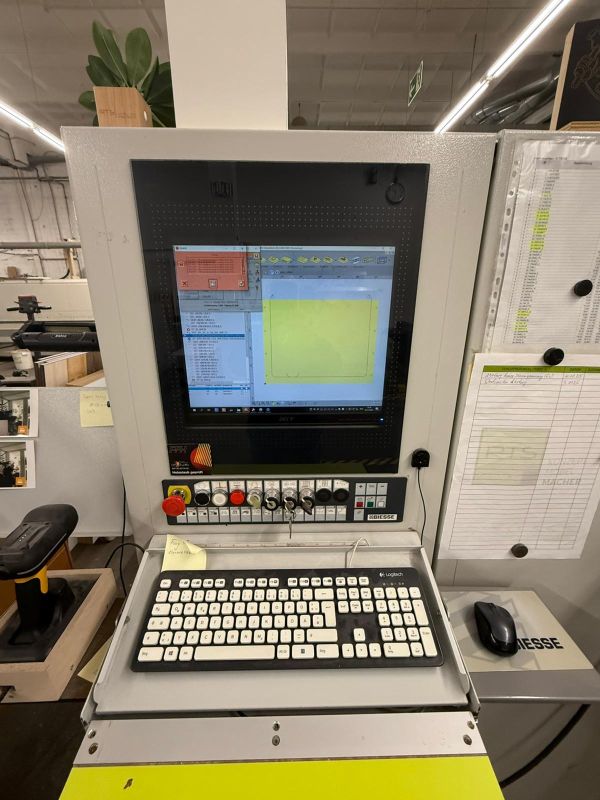

CNC machining center

Brand: Biesse

Type: Rover C 9.50

Year of manufacture: 2007

Technical data

- Working area: X=4600 mm / Y= 1935 mm / Z=275 mm

- CE safety devices

- 8 ATS plate holders - L = 1525 mm - 24 slide rails

- Automatic positioning of 8 plate holders and slide rails (EPS X-Y)

- Conveyor belt for removing chips and scrap pieces

- Pneumatic locking system, divided into 2 working areas in X

- 8 rear reference stops with a stroke of 115 mm

- 8 stops with a stroke of 140 mm, positioned at 1175 mm (L= 1280 - 1525 - 1800 mm)

- 8 stops with a stroke of 140 mm, positioned at 770 mm (L= 12 80, 1525, 1800 mm)

- 4 side stops with a stroke of 140 mm (2 Lh + 2 Rh) including pneumatic system.

- 4 removable center stops with a stroke of 140 mm (2 Lh + 2 Rh) including pneumatic system.

- Sensor for detecting lowered stops.

- Pneumatic system for lifting bar holders.

- 6 lifting bar holders for easy loading - H=74 mm modules.

- Vacuum system for a 250 m3/h pump

- 250 m3/h rotary vane vacuum pump for standard vacuum system

Composition C3-A1

- Device for mounting chip deflectors with pneumatic or inductive sensors on a 5-axis machining unit

- Flange for mounting units on a work unit with 5 interpolating axes *Units can only be used when the electric spindle is in a vertical position.

Composition C3-P2

- Additional Z slide for rear work units, controlled by an independent Z axis

- BH 42 L drilling head

- Chain tool changer with 22 positions at 180 mm center distance

- Iron gripper for chip deflector with pneumatic or inductive sensor, positioned in the chain tool changer

- RH chip deflector with inductive sensor for standard electric spindle or 15 kW 5-axis electric spindle * requires the device for the chip deflector * requires the flange for mounting units when using a 5-axis electric spindle * requires the C-axis when using a standard electric spindle

- Liquid cooling unit for liquid-cooled systems can cool two electric spindles or one electric spindle and one liquid-cooled drilling head.

- Automatic lubrication system

- Control unit with 5 interpolation axes This unit enables numerically controlled interpolation of the electric spindle on 5 axes. The electric spindle has high performance and reduced dimensions.

Note:

The technical data and descriptions are copies of the order confirmation at the time. The information is for informational purposes only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia