BrandALBERTI

typeVector SH

stateNew

stock number1110173

- Very well equipped point-to-point machine

- Fast working process

- Very good workpiece fixation

Questions about this machine

CNC drilling machine

Make: Alberti

Type: Vector SH

New machine

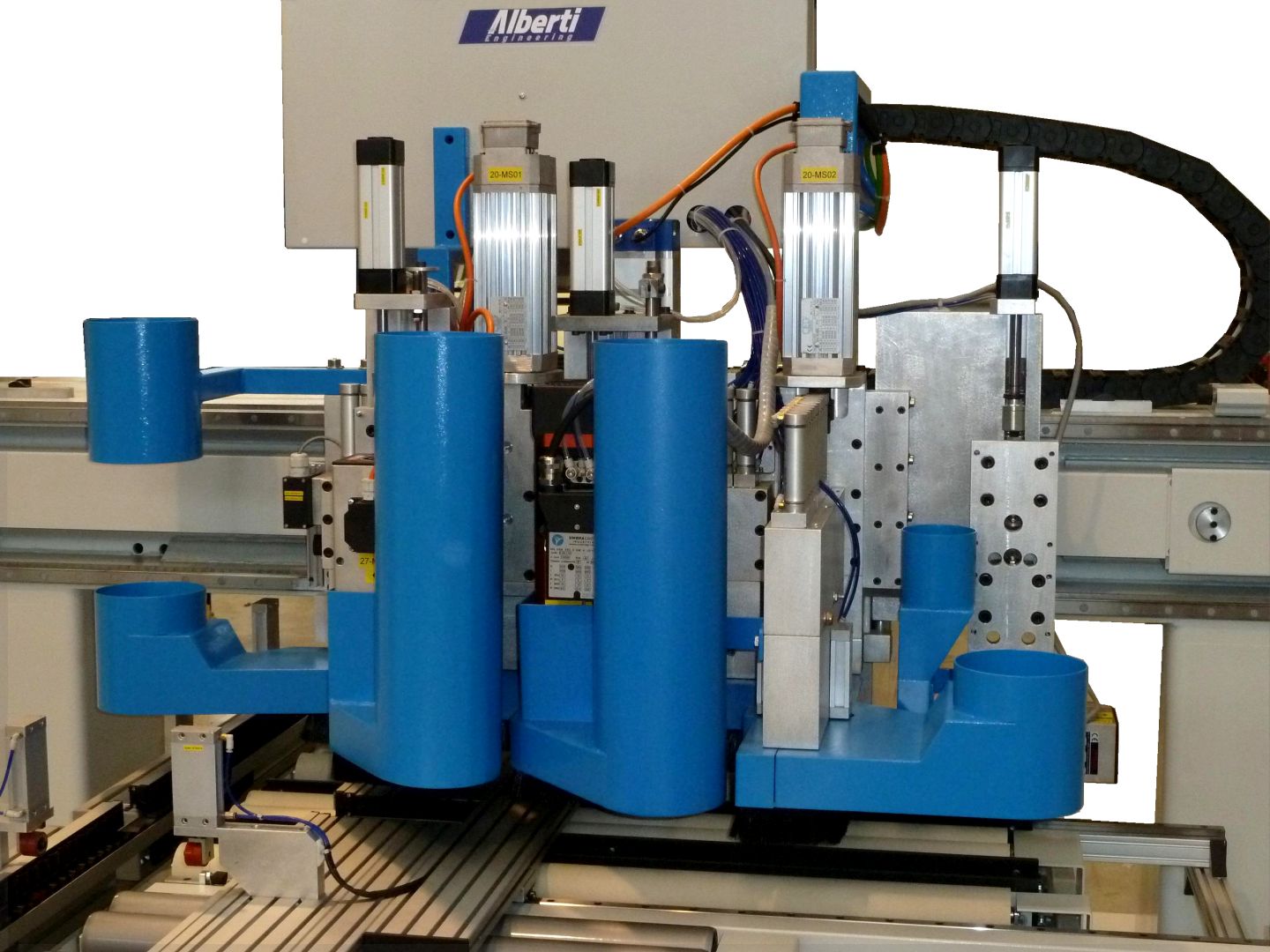

This CNC drilling machine machines workpieces from above with 29 spindles and has 4 controlled axes.

Optionally, the Vector is available as "Modulo-SH" with a total of two machining heads (top with 30 spindles and bottom with 7 spindles).

Machining head, working from above

Manual or automatic loading and stacking with longitudinal workpiece transport

Monolithic frame in welded strong steel

Independent control of all axes with drilling cycle optimisation

4 independent axes

X Workpiece transport along the X axis with vacuum suction cup for automatic alignment

Y Machining head

W Lateral pressure control

Z Machining depth control

Remark:

Max. Workpiece dimensions: 3000x1200x50mm

Min. workpiece dimensions: 300x130x12mm

Geometry of workpieces: Length > Width / Length = Width / Length < 20% Width

Machining head in L-shape with another workpiece clamping system

- 29 vertical spindles:

18 vertical spindles, central in Y-direction

1 horizontal boring head with 2 outlets in X-direction with vertical clamping cylinders

10 vertical spindles, central in X-direction

1 horizontal drilling head with 2 outputs in Y-direction with vertical clamping cylinders

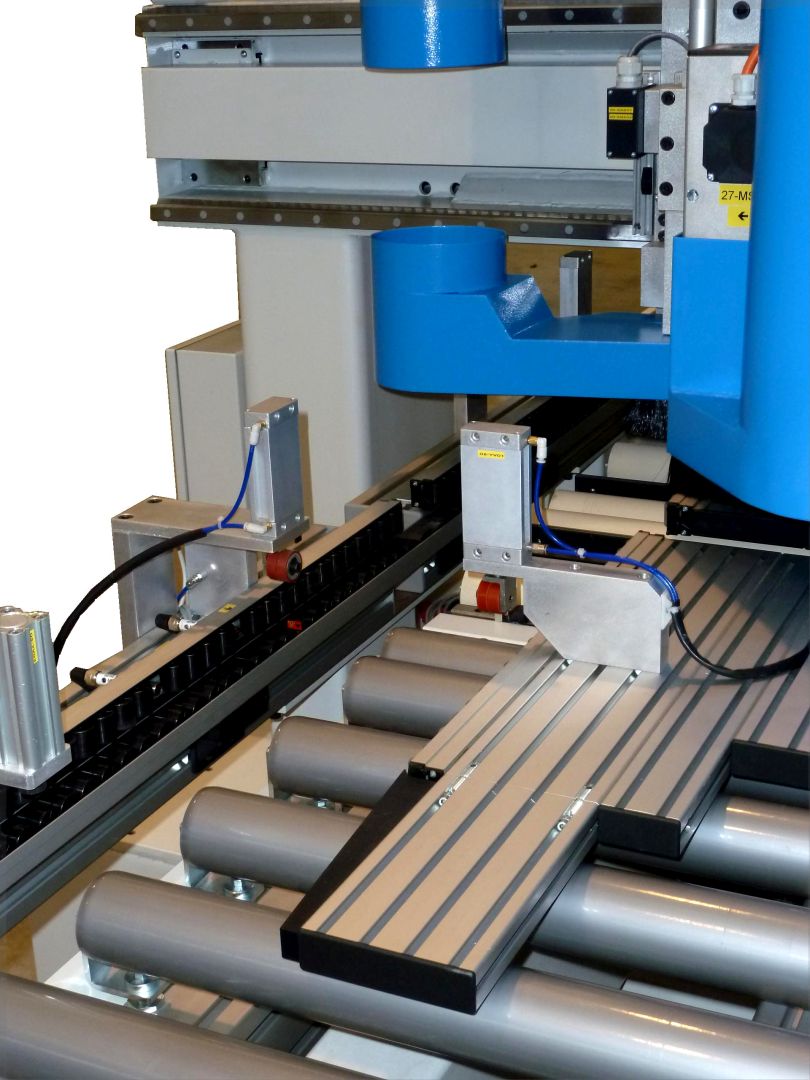

Work table:

- Driven PVC rollers at the infeed

Usable length: 2000mm, usable width: 840mm

- Reference table with PVC rollers

Usable length: 1000mm, working height: 920mm, adjustable +/- 30mm

- Driven PVC castors at the outlet

Usable length: 2000mm, usable width: 840mm

- Vertical workpiece clamps, automatically adjusted to workpiece thickness

- Automatic zero-point detection in X-direction at workpiece start and end

- Lamp to indicate workpiece clamping and machining mode

- Workpiece release for position correction

Angular unit

TPA Albatros software

Optionally available at extra charge:

Drilling units:

Horizontal drilling heads: in X-direction, 2 outputs and vertical workpiece clamps, drilling depth max. 50mm

Horizontal drilling heads: in Y-direction, 2 exits and vertical workpiece clamps, drilling depth max. 45mm

Monoblock 13 Vertical spindles in X-direction

Monoblock 15 Vertical spindles in X-direction

Drilling unit, separately driven for fitting holes

Inverter for high-frequency units

Grooving saw in X-direction 1.8 HP, Ø 150mm

Grooving saw in X-direction and Y-direction 1.8 HP, Ø 150mm

7 hp electric spindle, 12,000-18,000 rpm, tool Ø 20mm, CPE holder, manually interchangeable

9 hp electric spindle, 12,000-18,000 rpm, tool Ø 20mm, HSK 63 F attachment, manual or automatic

4-fold tool changer for tools with max. 40mm Ø

HSK 63F cone

C-axis

Uninterruptible power supply PC

PLC functions for control of automatic loading and destacking

Preparation basic version for fittings

Preparation basic version for storage

Preparation basic version for drawer runners

Dongle for offline editor functions

Barcode reader

Additional vacuum suction cup for alignment

The machine is also available in version "Modul O-SH":

A total of 2 drill heads (top and bottom) and two vacuum suction cups for autom. workpiece alignment and transport.

The drilling head above is equipped with 30 spindles and the drilling head below with 7 spindles.

Price of the standard equipment: 166.000,00 € (+VAT)

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia