BrandCOSMEC

typeSmart 30, 5 Achsen

stateNew

stock number1110231

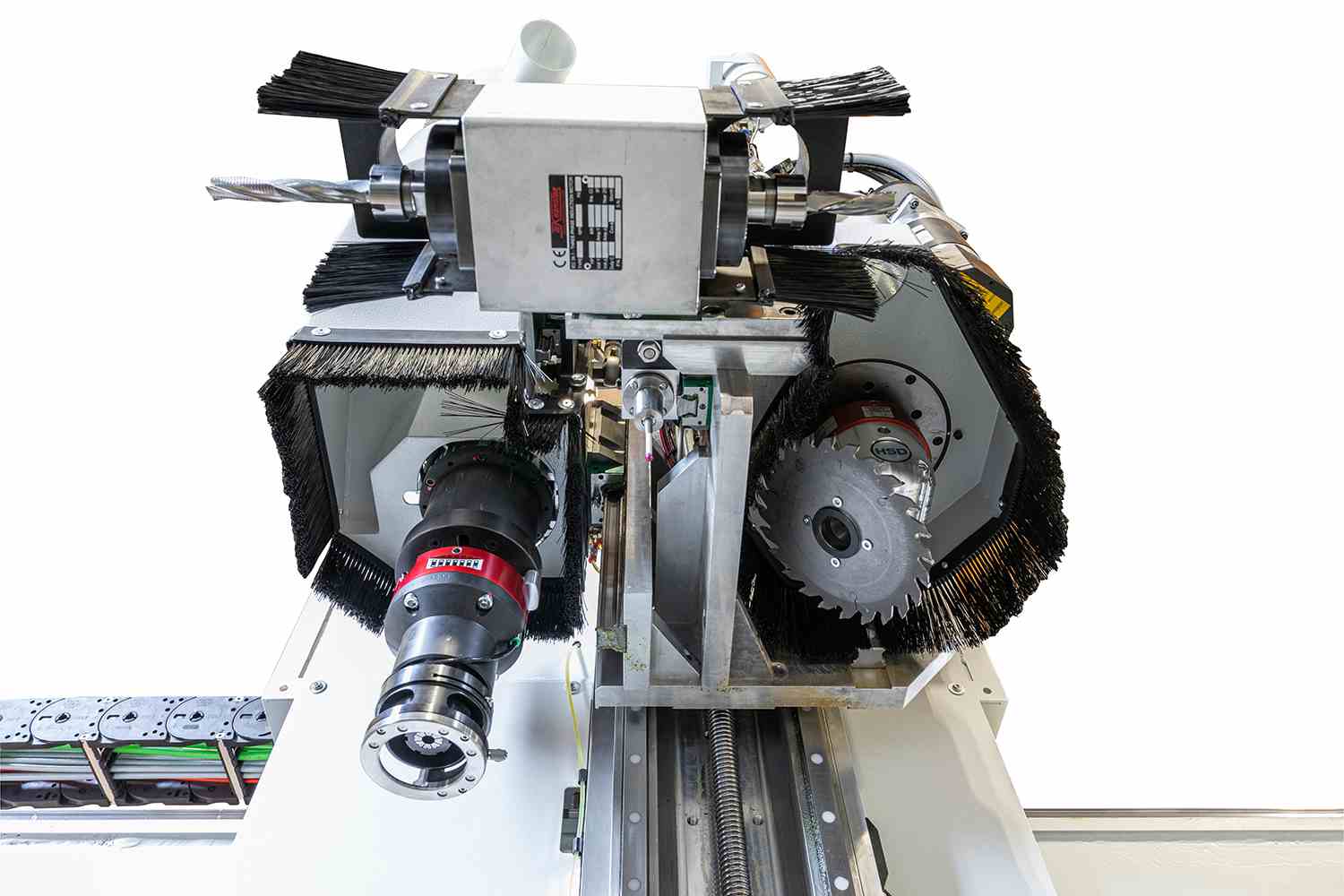

- Insgesamt 2 Frässpindeln (1 mit 5. Achse)

- 10-fach Tellerwechsler

- 10-fach linearer Wechsler

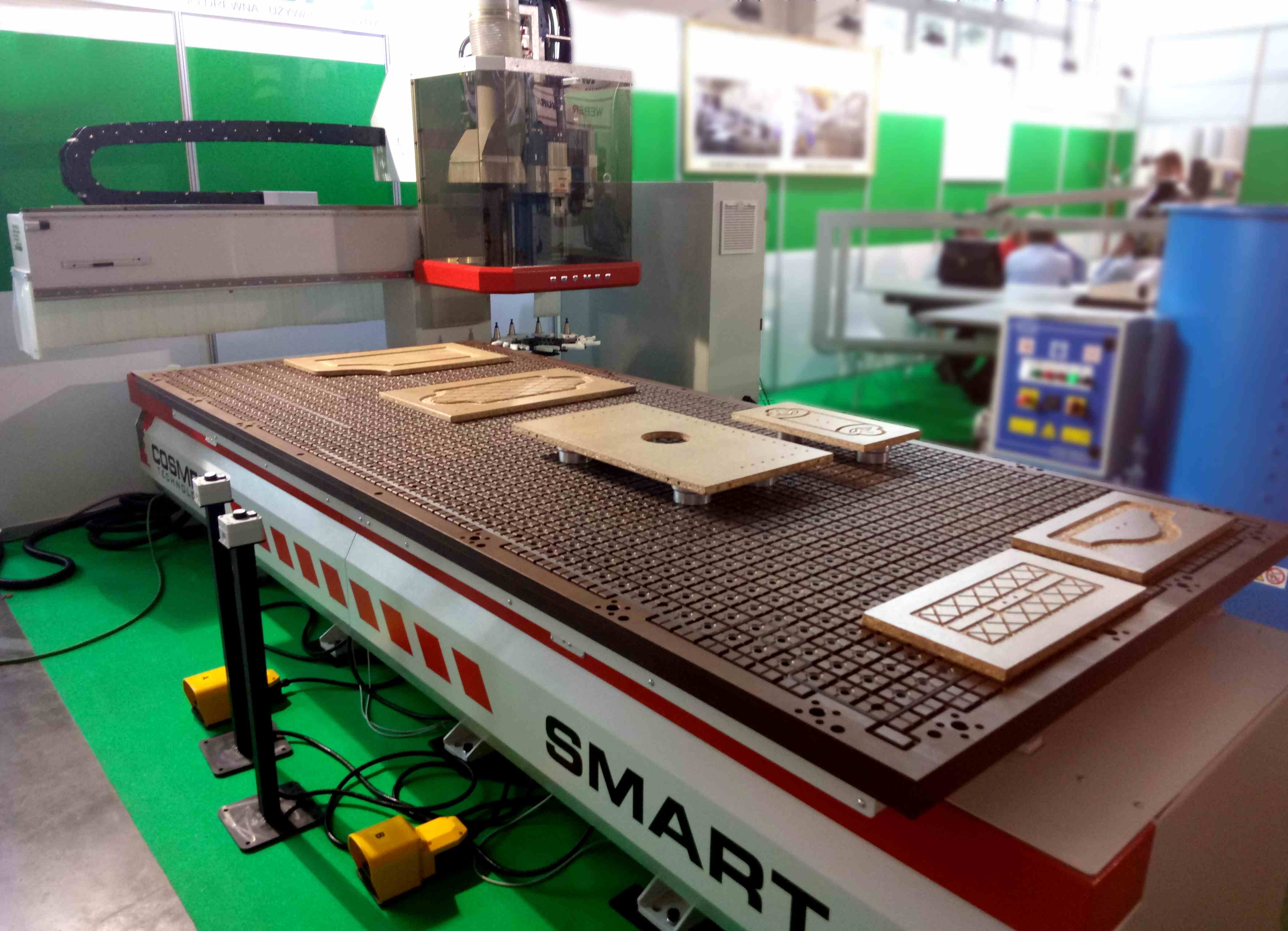

- Cosmec Rastertisch besonders gut zur Bearbeitung leichter / kleiner Werkstücke

Questions about this machine

New CNC working machine

brand: Cosmec

Type: Smart 30, 5 Achsen

Configuration example: other equipment possible on request

The smart serie:

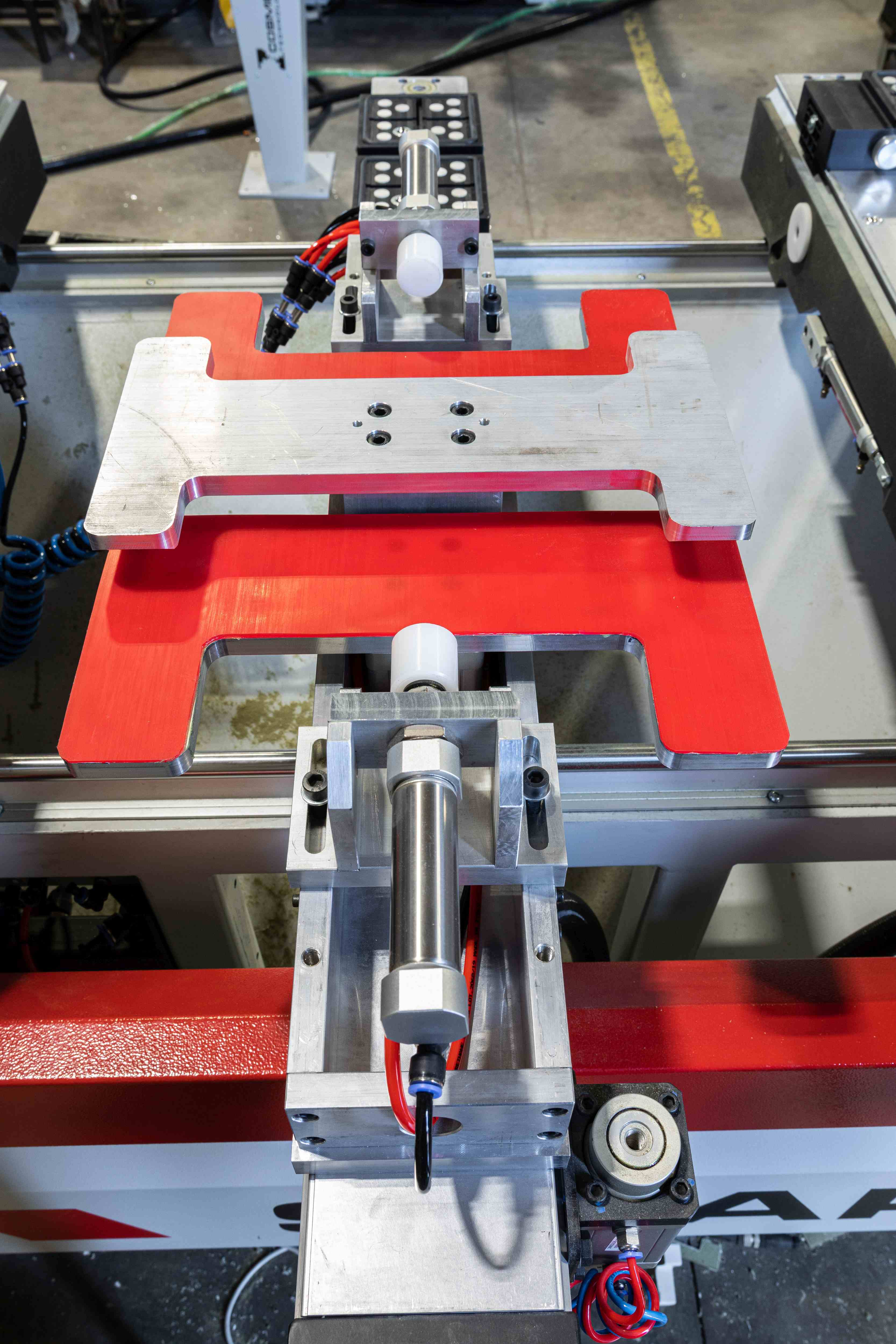

- Flexibility through cantilever construction

- Best equipped for door processing

- Protection by laser system (instead of step mats)

- Especially good for machining light / small workpieces

The controlling:

OSAI CNC system control + Aspan CAD-CAM software:

- Aspan uses simple commands to execute the machining process

- By entering dimensions you can precisely position the machining operations

- The machining operations are displayed on the virtual workpiece.

- Diverse macros facilitate programming (of holes, slots, linear milling, arc milling...)

Aspan Doors

- Software module for easy creation of programs for door processing.

- Different door types are already stored (doors with milled arches, round doors...)

- Doors can be modified individually

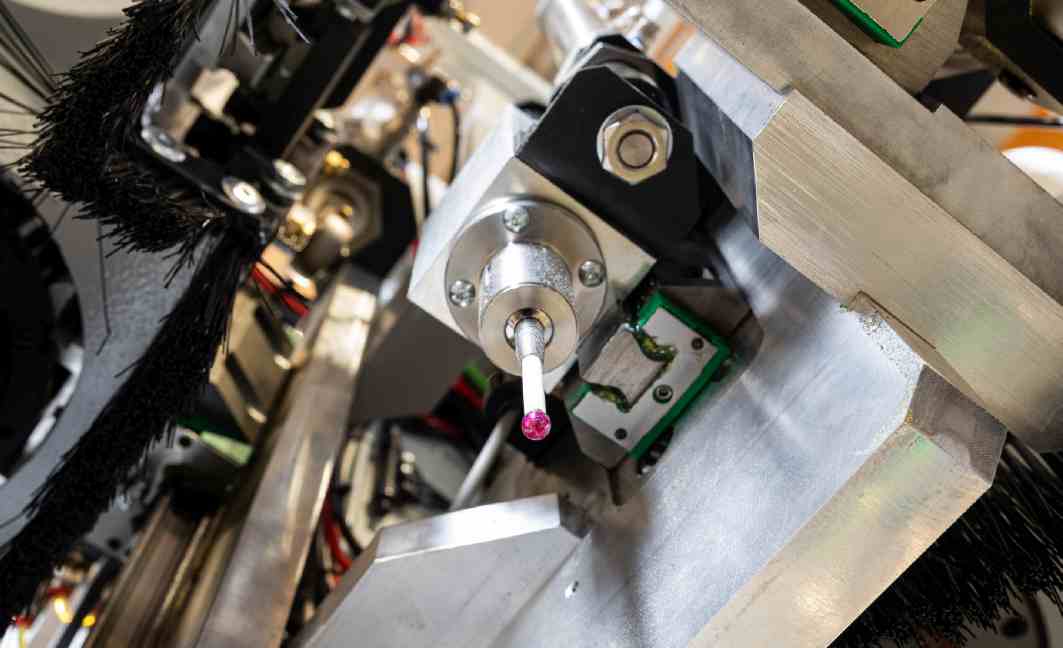

The drill head:

- guided on one side

- C and B axes driven by brushless motors

- C-axis rotation +/- 220

- B-axis oscillation +/- 110

The Cosmec work table:

- consisting of Bakelite

- Sandwich structure with milled chamber system for a highly concentrated vacuum

- openings with 150mm grid

- Subdivision into two vacuum fields

- use of vacuum cups possible

- 4 sets of 3 stops each to position as accurately as possible

- More flexibility thanks to the cantilever structure

- Guides: X-axis by rack and pinion, Y- and Z-axis by recirculating ball screw

- Drive by brushless motors

The vacuum system:

- Designed for the productive pendulum process

- Workpiece fixing by a 250/300 m³/h vacuum pump

Autom. central lubrication

Protection by tread mats

Switch cabinet cooling

Technical data:

Rapid traverse:

- X-axis: 60 m/min.

- Y axis: 60 m/min.

- Z axis: 15 m/min.

- Vector speed: 90 m/min.

Axis travels:

- X-axis: 4,550mm (optionally extended to 5,100mm).

- Y-axis: 1.790mm

- Z-axis: 750mm

Machining area: 4100x1350mm

Max. Workpiece thickness: 250mm (with Cosmec grid table)

Max. Workpiece thickness: 200mm (when using a vacuum suction cup)

13 kW 5-axis milling spindle

- liquid cooling

- CNC programmable speed from 500-24.000 rpm

- HSK 63 F mounting

- direction of rotation: left/right

Suction hood movable in 4 positions

12 kW milling spindle

- air cooling

- CNC programmable speed from 500-24.000 rpm

- HSK 63 F mounting

Automatic plate changer with 10 positions, HSK F63

Max. Tool-Ø:

- 150mm (when auxiliary positions are occupied)

- 250mm (with free secondary places)

- Tool length 200mm

- Max. 2 aggregates

- Max. 6 kg weight per tool / aggregate

- Max. 40 kg total weight

Linear tool changer with 10 positions, ISO 30 / HSK 64

Max. Tool Ø: 120mm

- Tool length 150mm

- Max. 3 kg weight per tool / unit

- Max. 30 kg total weight

Autom. tool length measurement

your contact person

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia