BrandWILD

stateUsed

stock number0401834

year1998

For door dimensions:

- Lengths: 1,800 - 2,300 mm

- Widths: 500 - 1,300 mm

- Thicknesses: 35 / 40 / 44 mm

Questions about this machine

Door production line

Brand: Wild

Year of construction: 1998

For door dimensions:

- Lengths: 1,800 - 2,300 mm

- Widths: 500 - 1,300 mm

- Thicknesses: 35 / 40 / 44 mm

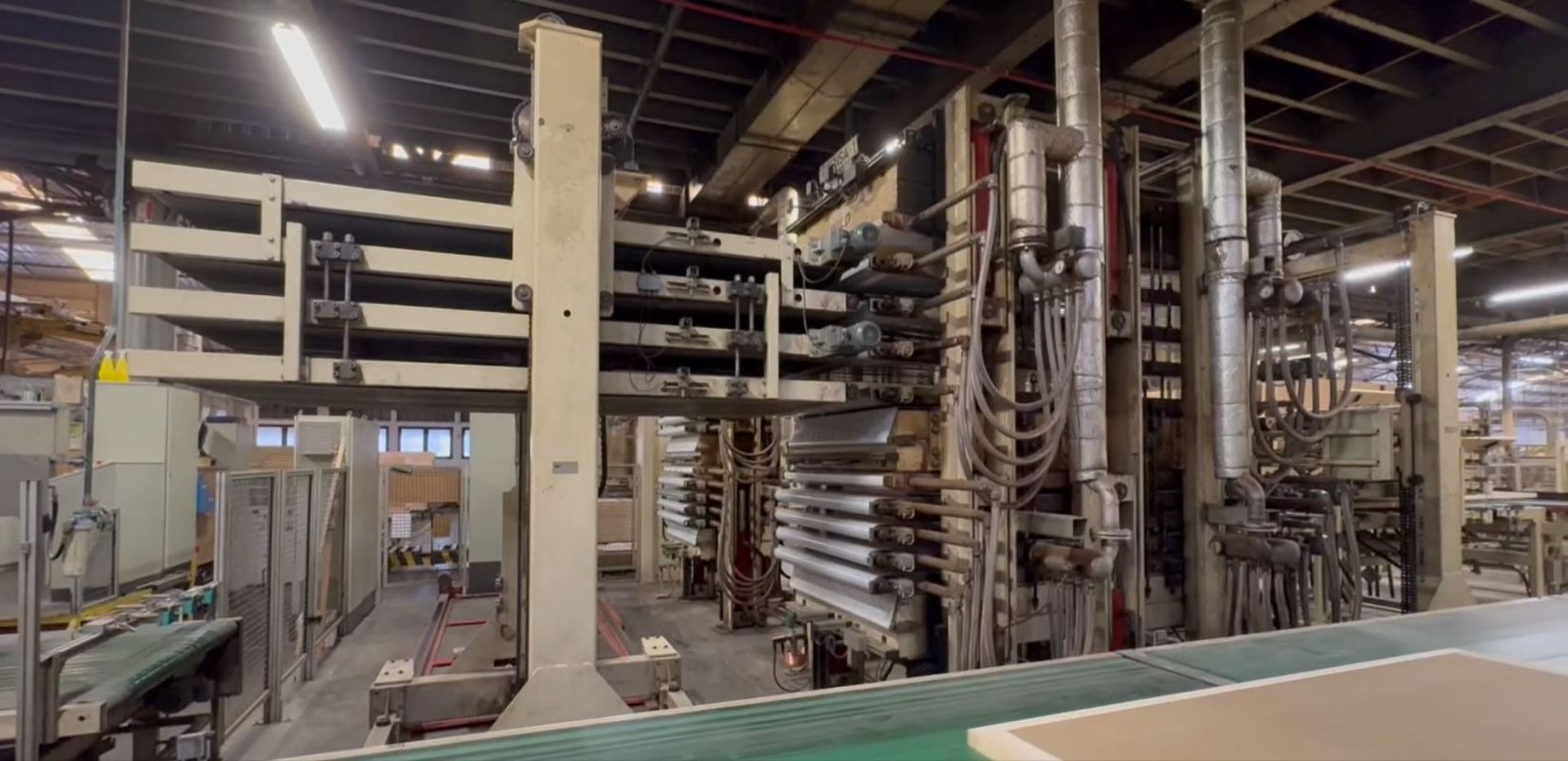

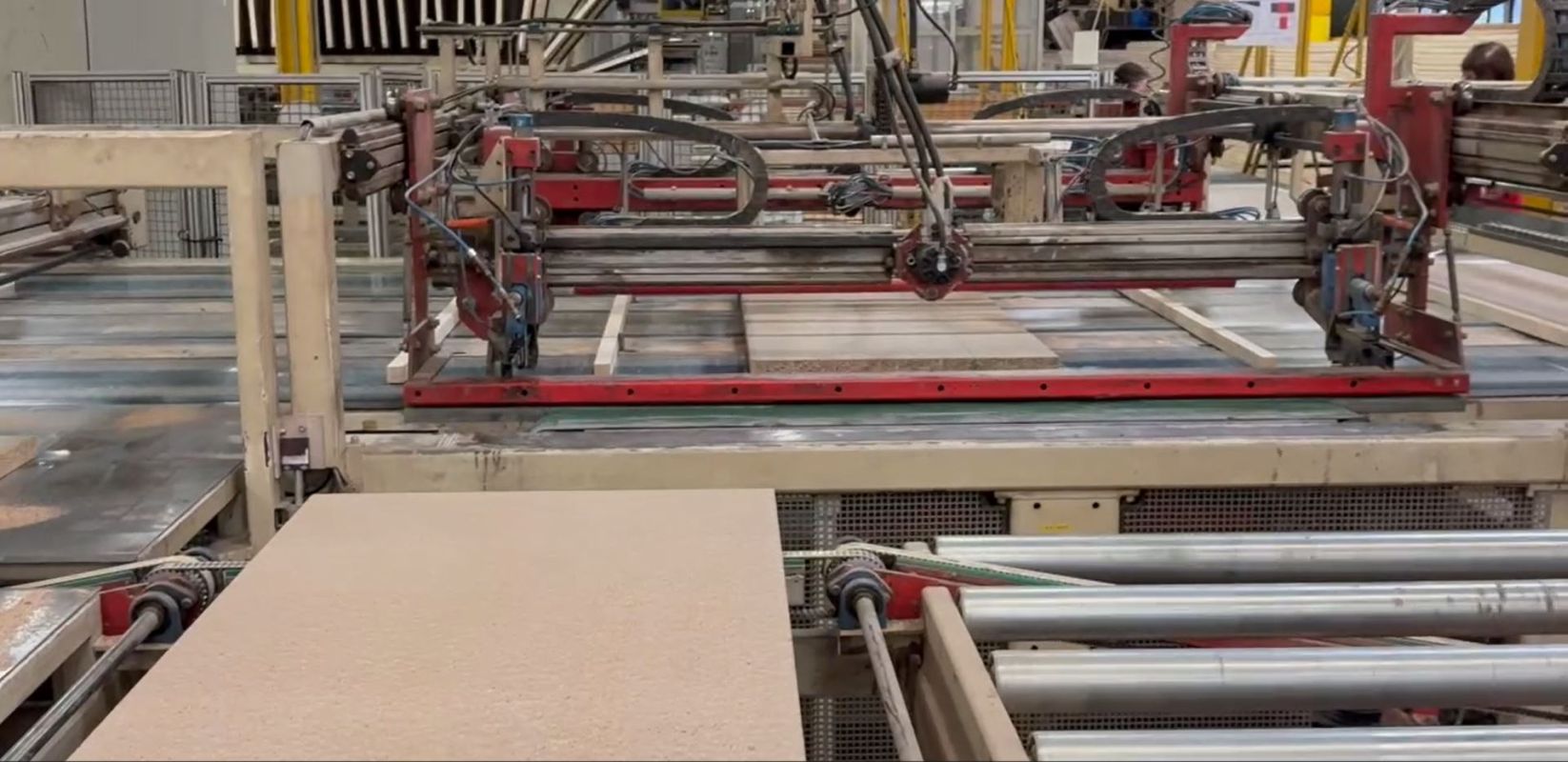

Consisting of the following areas: 1. endless door panel gluing with frame laying station / 2. press line with hard fiberboard loading station

1. area consisting of

- Portal feeding

- Angle transfer with rip and cross cut saw

- Feeding and supply of longitudinal and cross frame parts from magazines

- Longitudinal cross-cut station for the longitudinal frame parts

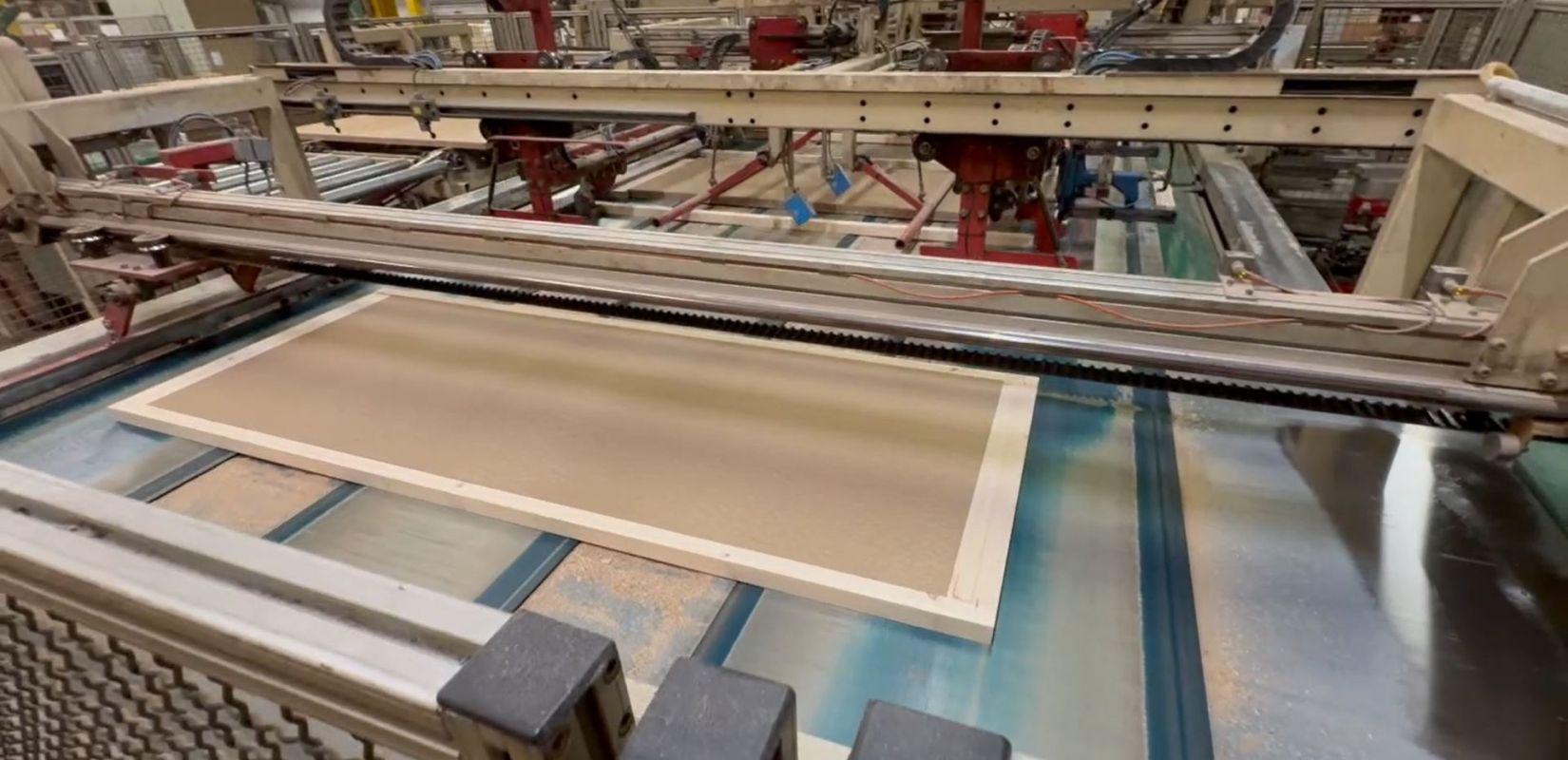

- Connecting station for the frame parts with the door leaf core. With clamping devices

- Conveyor belt angle transfer with shuttle transfer of the door leaf cores to the glued hardboard panels

2. area consisting of:

- Feeding of the hardboard panels

- Brush cleaning machine

- Hardener application machine from below

- Glue application machine from below

- Disk roller conveyor

- Angle transfer for the lower hard fiber board

- Vacuum turning device for the upper hard fiberboard

- Automatic loading station for hardboard panels and door leaf cores

- 2 door presses with 2 x 4 pressing stations each, set up parallel to each other

- Both presses are loaded at the infeed with 1 shuttle loading basket

- Both presses are unloaded at the outfeed with 1 shuttle unloading basket

- Angular transfer to the infeed into a hedgehog buffer

- Angular transfer at the outlet of the hedgehog buffer and feeding for stacking

- One-sided vacuum destacking with protective plate place

Note:

The technical data and descriptions are transcribed from the original order confirmation. The information is for reference only and is not legally binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia