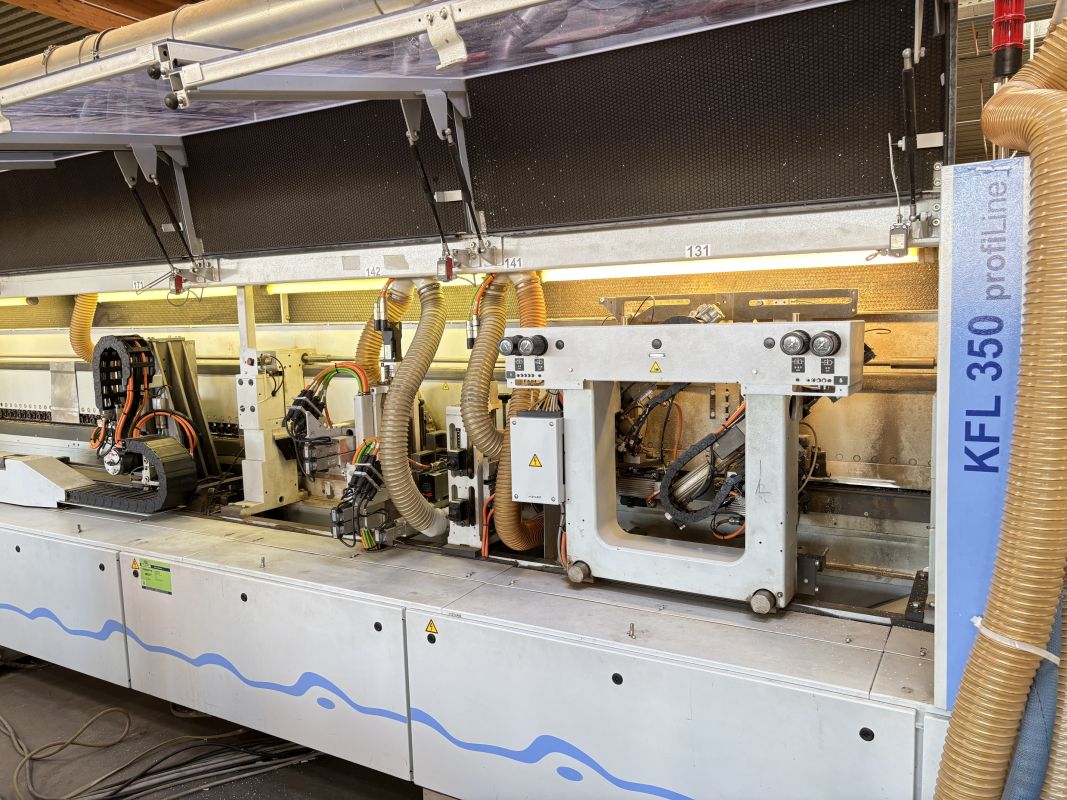

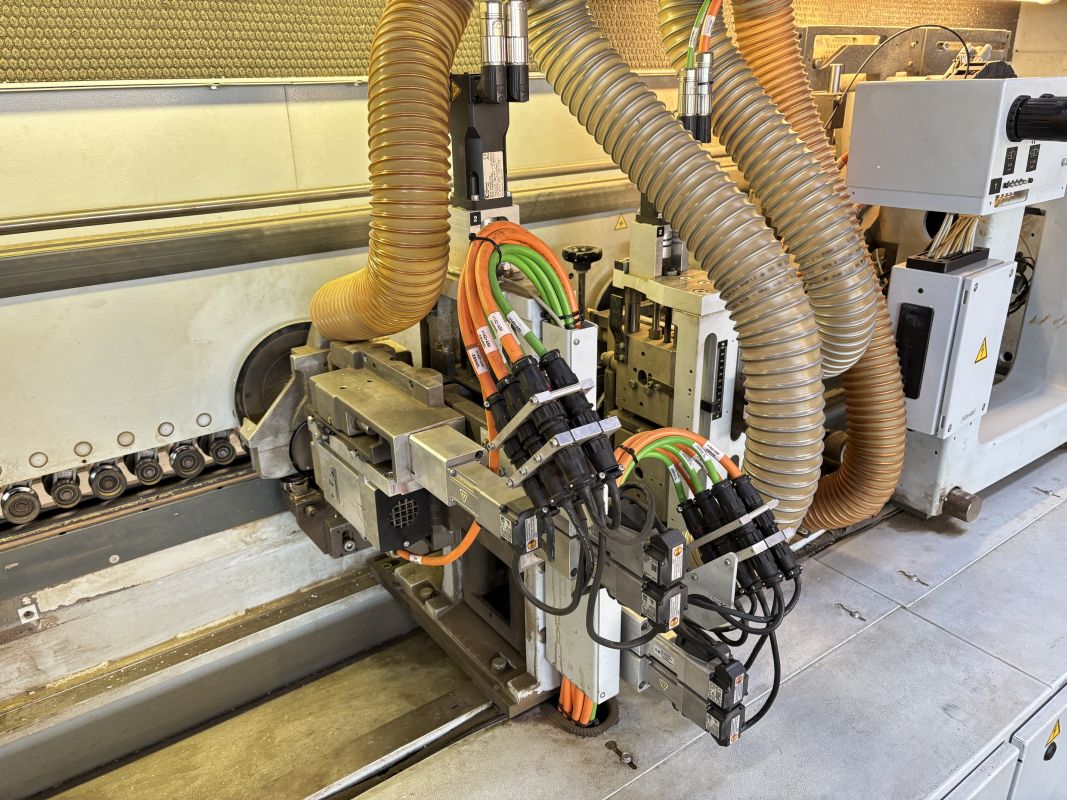

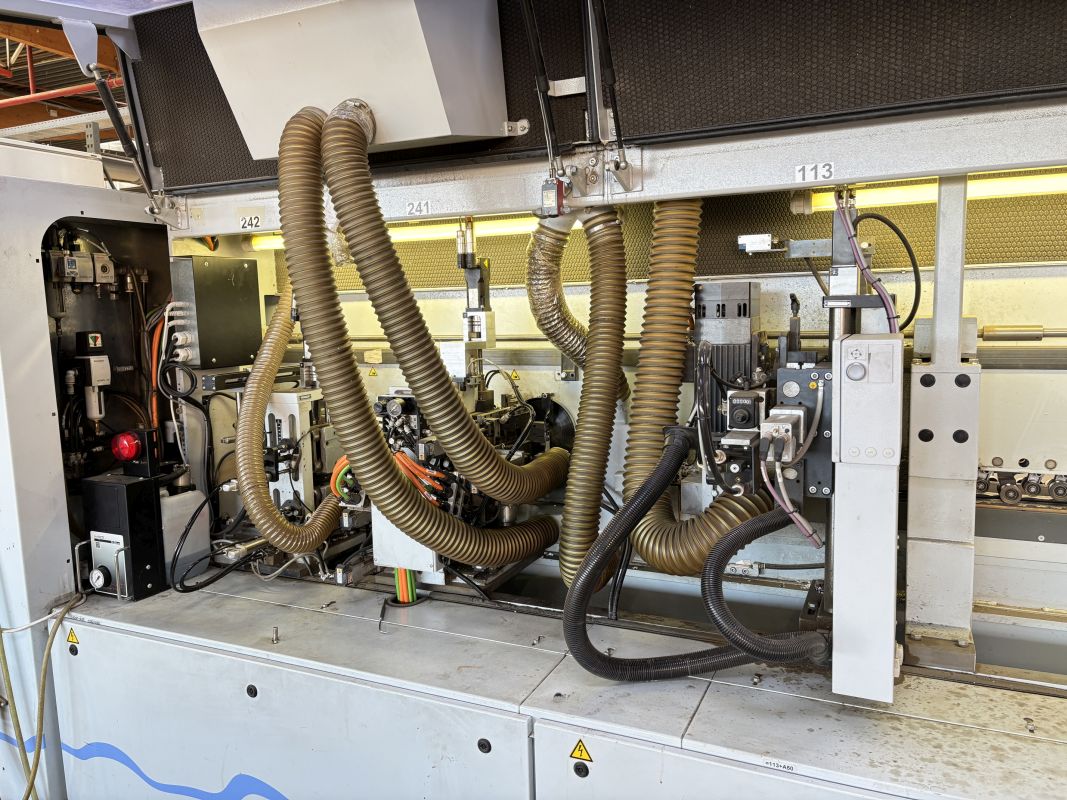

single-sided edge banding machine with loading table and workpiece return

Brand: Homag

type: KFL350/12/A3/L/WZ

Year of construction: 2011

Feeding table

Brand: Homag

Type: Profi TBL100/20/30/F

Year of construction: 2011

Return conveyor

Brand: Ligmatec

Type: ZHR30/L/155/F

Year of construction: 2010

Technical data of the feeding table

Basic machine:

- Feed rate: 7 - 40 m/min

- Working height: 950 mm +/- 50 mm

- Pneumatic connection: 7 - 8 bar

Workpiece parameters:

- Workpiece length min. : 240 mm

- Workpiece length max. : 2500 mm

- Workpiece width min. : 120 mm

- Workpiece width max. : 3000 mm

Adjusting device side stop Automatic

- Adjustment range max. 80 mm

- Centralised adjustment via stepless axis to adapt to different workpiece protrusions

Technical data of the single-sided edge banding machine

Basic machine:

- Feed rate: 18 - 32 m/min

- Working height: 950 mm

- Pneumatic connection: 7 - 8 bar

Workpiece and edge parameters:

- Workpiece width min (for workpiece thickness 12-22 mm): 60 mm*

- Workpiece width min (for workpiece thickness 23-60 mm): 100 mm*

* Depending on the workpiece length

- Workpiece protrusion: 30 mm

- Workpiece thickness: 12 - 60 mm

- Edge material roll: 0.3 - 3 mm

- Max. edge cross-section :

For PVC: 135 mm²

For veneer: 100 mm²

- Max. roll diameter: 830 mm

Compact - Double hogger lengthwise/crosswise 6,6 kW KD 11

- 1 motor 4.5 kW, 100 Hz, 6000 rpm

- Motor shaft Ø 35x70 mm

Joint trimming unit KAL300/S2

For routing the workpieces before gluing

- 2 motors each 3 kW, 150 Hz, 9000 1/min

- Motor shaft Ø 30x68 mm

- Workpiece thickness max. : 40 mm

Lasertec activation unit 3 kW

Laser unit:

- for melting the laser activation layer on the edgeband material

- Oscillating laser beam

- Automatic adjustment to the workpiece thickness

- Laser beam wavelength 980 nm

Laser safety device:

- Laser certificate protection class 1

- The laser corresponds to laser protection class 4 and is converted to laser protection class 1 by the protective device

Machining parameters:

- Workpiece thickness: max. 40 mm

- Feed rate depending on edge material and workpiece thickness: max. 30 m/min

- Roll edge thickness: max. 3 mm

- Stiffener edge thickness: max. 3 mm

Pressure zone:

- Large printing roller: Ø 150 mmstraight

- For A3 - gluing part Ø 150 mm, instead of 90 mm, therefore min. edge length + 40 mm

- Re-pressing rollers: 3 straight re-pressing rollers

Compact gluing unit PU34 On. Hot melt adhesive

Instead of standard hot-melt adhesive unit

- Melting capacity max. 6 kg/h depending on the adhesive

- Container size 2 kg

- Glue application unit QA34 for PU

Pressure tank for PU - Glue container front part

Preheating station for application unit

Quick clamping system for application unit QA

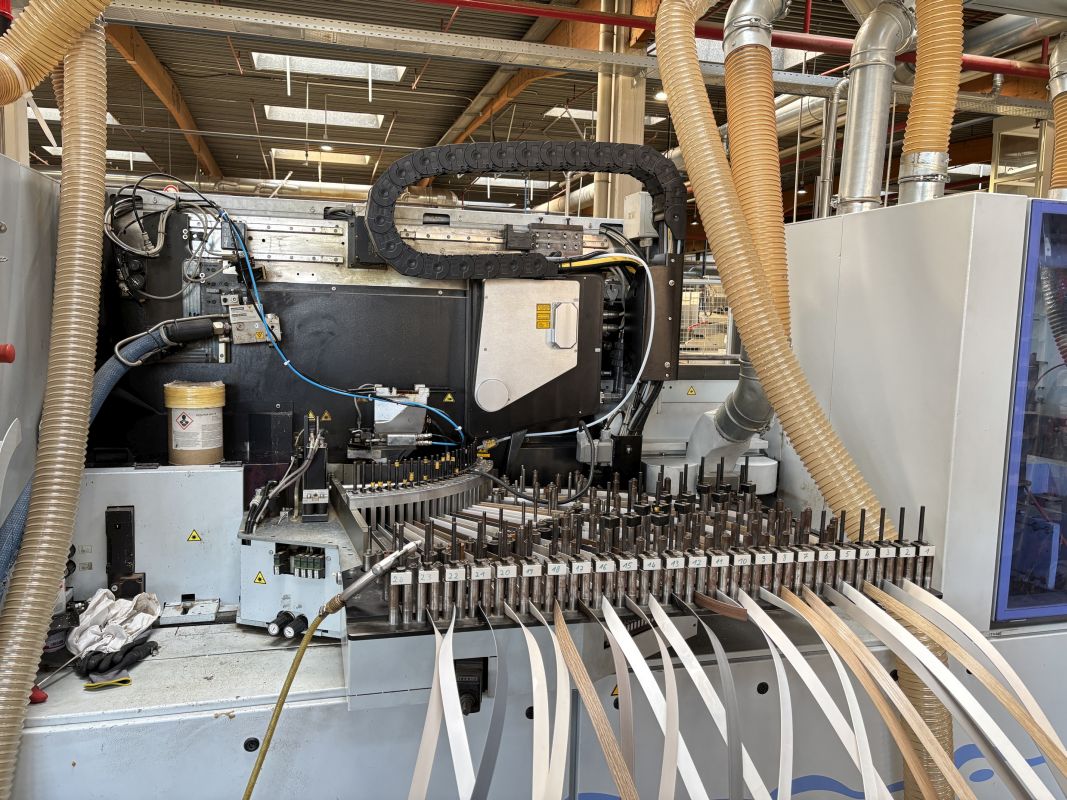

Extension magazine A3 to 24 rolls

- Edge thickness: 12 x 0.3 - 3 mm, 12 x 0.3 - 2 mm

- Edge width: 12 - 45 mm

- Roll diameter: 12 x 830 mm, 12 x 600 mm

- Processing max.: for PVC 135 mm², for veneer 100 mm²

- Manual magazine adjustment: 10 mm

- Roll separating device

- Roll change 12 x 2 rolls automatic or 24 x 1 roll manual

- Edge monitoring with virubust stop

- Remaining length monitoring at 2400 mm

Pressure zone A

- 1 driven pre-press roller Ø 90 mm

- 4 post-press rollers Ø 70 mm

- Pneumatic pressure adjustment

Divided pressure zone

- For set-up gap of at least 500 mm at a feed speed of 20 m/min

- Servo axes for large pressure rollers with two pinch rollers

- Servo lugs for 4 pinch rollers

Servo edge feed for A1 - A20

- Edge feeding of the roll material via servo drive

- Max. edge protrusion on the front and rear edge when processing roll material: +/- 3 mm at a feed rate of up to 50 m/min

Stepless edge hold-down device

Edge thickness measurement

Cross-cut unit chamfer/straight HL84/ 0.22 kW

- Vertical cross-cut fence

- 2 motors each 0.22 kW, 200 Hz, 12000 l/min

- Pneumatic adjustment for converting from bevelled to straight cross-cuts

- 2 HM cross-cut saws with HSK25 Ø 120 mm

- Workpiece protrusion: min. 30 mm

- Straight edge thickness: max. 3 mm

- Bevelled edge thickness: max. 3 mm

- Chamfer 30°

- Workpiece thickness: max. 60 mm

- Top edge protrusion, above workpiece surface: max. 4 mm

- Edge width: 65 mm

- Feed speed:

up to workpiece thickness 40 mm: max. 25 m/min

up to workpiece thickness 60 mm: max. 20 m/min

Pneumatic adjustment of snipping motor

- Position 1: Flush snipping

- Position 2: Caps with overhang - for re-milling with profile trimming unit

Pre-moulding unit 0.55 kW

- 2 motors one above the other, each with 0.55 kW, 200 Hz, 12000 l/min

- Height adjustment with top pressure

- 2 carbide cutters 70 x 25 mm, HSK 25, Z=4

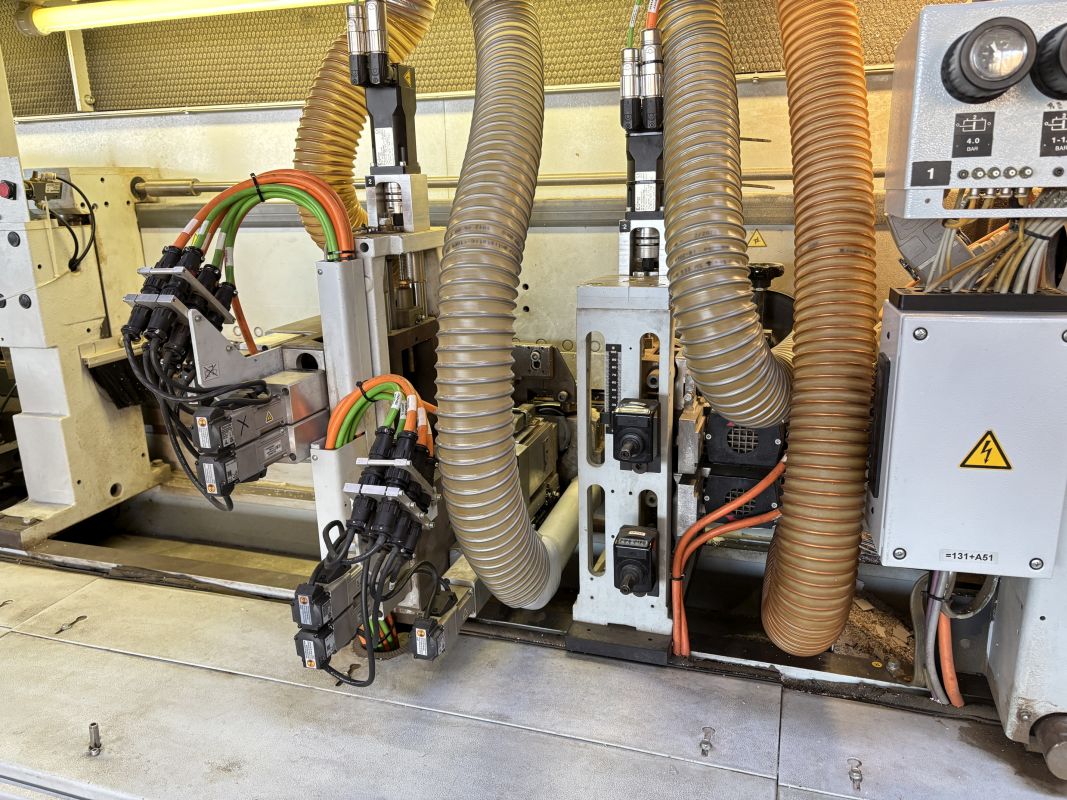

MF21 Servo multi-milling unit

- For bevelling different edges up to max. 3 mm edge thickness and for radius routing R=2 or R=3 with one combination tool

- 2 motors each 0.55 kW, 200 Hz, 12000 1/min

- Edge thickness: max. 3 mm

- Workpiece thickness R=3 mm: min. 13 mm

- Workpiece thickness with chamfer 0.5 x 45°: min. 10 mm

- Workpiece thickness with chamfer 20° and edge thickness 0.4 mm: min. 8 mm

- Workpiece length: min. 110 mm

- 2 I-DIA milling cutters HSK25, Z=4, designed for chamfer 20° and radii R=2 and R=3

Release agent spraying unit top/bottom

Moulding unit FK31/30 cycles

- 1 motor 0.75 kW. 12000 1/min

- Infinitely variable speed adjustment to edgeband material via programme

- Feed rate: max. 30 m/min

- Workpiece length at reduced feed rate: min. 120 mm

- Workpiece thickness 8 - 60 mm

- Power reduction for workpiece thickness > 40

- Edge thickness: max. 3 mm

- Workpiece protrusion: min. 30 mm

- Smallest contour radius R=41 mm

- Max. number of cycles: 30 cycles/min

- Moulding of veneer and solid edges is only possible to a limited extent

Universal routing unit UF11 controlled 4 kW

-1 Motor 4 kW, 150 Hz, 9000 1/min

- Motor shaft Ø: 30x68 mm

- swivelling: max. 90°

- Groove position: minimum distance 10 mm to chain track or top pressure

- Tool diameter: max. 150 mm

Push button with HSK63 F MOD attachment Standard shaft

- HSK63 F Mod interface instead of standard shaft

- Tool length: max. 75 mm

- Standard milling:

Can be used with motors with 6.6/8.1/11 kW

Tool weight: max. 15 kg

- Universal milling cutters

Can be used with motors with 4 kW

Tool weight max. 6 kg

Stepless horizontal axis for UF11

Vertical stepless axis for UF11

Multi scraper blades MN21 Servo with chip breaker

- For chamfering or rounding pre-milled PVC edges

- Edge thickness: max. 3 mm

- Workpiece thickness with R=3 mm: min. 13 mm

- Workpiece thickness for chamfer 0.5x45°: min. 10 mm

- 2 carbide knives designed for chamfer 20°, R=1.5/ R=2/ R=3/ R=5

Profile knife set F. MN20/21

Finishing unit FA11 top/bottom

consisting of:

- Glue residue removal

- Cleaning agent application

Note:

The technical data and descriptions are transcribed from the original order confirmation. The information is for reference only and is not legally binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia