BrandSCHUKO

typeVacomat 350 XP Twin

stateNew

stock number1110283

- Powerful extraction center for entire machine

parks

- Energy-saving miracle thanks to performance-

adapted fan control

- Dust-tested: H3 test mark, dust class “M”

- Can be combined with various chip discharge

systems

Questions about this machine

Mobile extraction unit

Brand: Schuko

Type: Vacomat 350 XP Twin

New machine

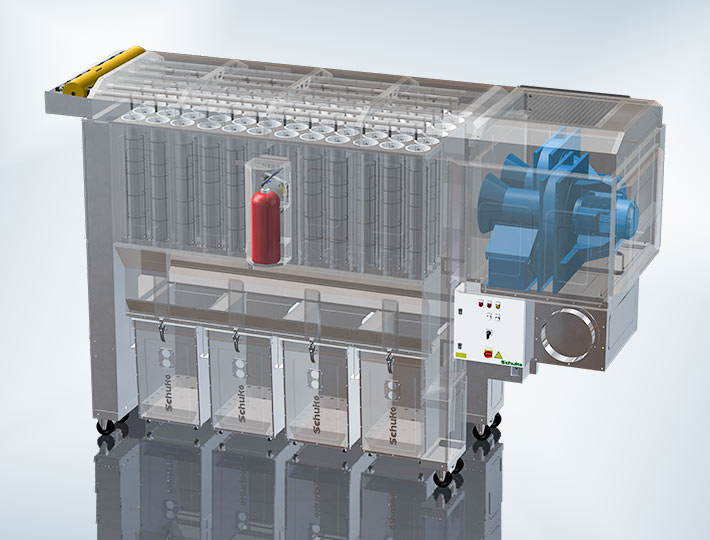

The Vacomat 350 XP TWIN large dust extractor is a real energy-saving miracle among mobile dust extractors.

Two frequency-controlled motors (5.5 kW each) ensure, especially under strongly changing operating conditions,

for a correspondingly adapted extraction performance. This means that only as much energy is consumed as is actually needed.

This dust extractor conveys air volumes of up to 10,000 m³/h and is ideal for extracting large CNC machines or entire machining centers.

The innovative and highly intelligent control system automates the extraction process with the machines connected in the network.

Extraction starts automatically as soon as a connected processing machine is switched on.

If less power is required, only one fan is started. As soon as several extraction points are running, the second fan is automatically switched on.

As standard, cleaning of the filter bags starts automatically during breaks in operation as soon as all connected processing machines are switched off.

The patented filter shaker then ensures gentle cleaning pneumatically/mechanically via a compressed air connection by means of a kind of “knocking out” (inlet pressure 6 bar, air requirement per cleaning cycle approx. 11 l).

An efficient pressure surge cleaning system is available as an option, especially recommended for very high and particularly fine dust content such as plaster dust.

Cleaning via the compressed air tank takes place offline, after extraction operation (ATTENTION: overall height then +100 mm and length +350 mm).

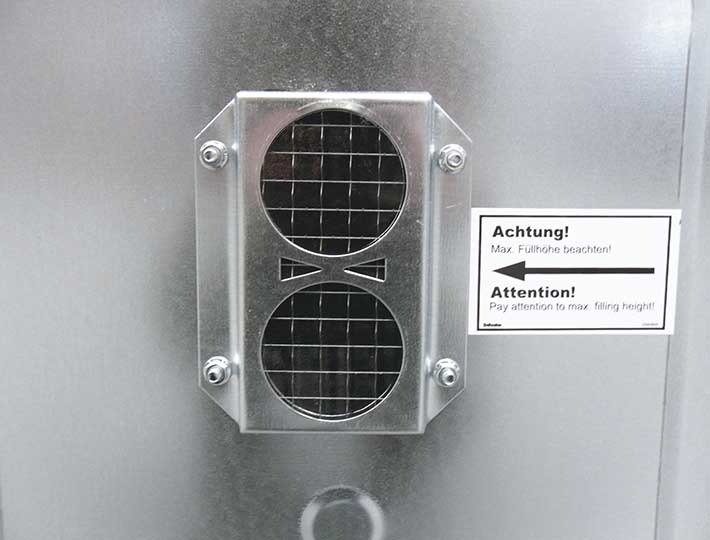

The Vacomat is manufactured according to the modular principle. As standard, the dust-chip mixture is discharged into four dust-tight chip collection garbage cans (4 x 120 l) with inserted, sturdy plastic bags. A vacuum channel holds the plastic bags securely in the collection container. Viewing windows make it easier to check the fill level.

Alternatively, the dust extractor is also available with discharge into a briquetting press (with upstream chip container) or into BigBags, a container or chip bunker (with upstream ATEX rotary valve and screw conveyor).

Technical data:

Suction nozzle Ø (mm) 350

Motor power (kW) 2 x 5.5

Volume flow (m³/h) 10,000

Nominal volume flow at 20 m/s (m³/h) 6927

Negative pressure (pa) 2550

Filter area (m²) 50

Sound pressure level (dB[A]) 69

Weight (kg) 1,160

Chip collection volume (l) 4 x 120

Dust-tested: H3 test mark, dust class “M”

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia