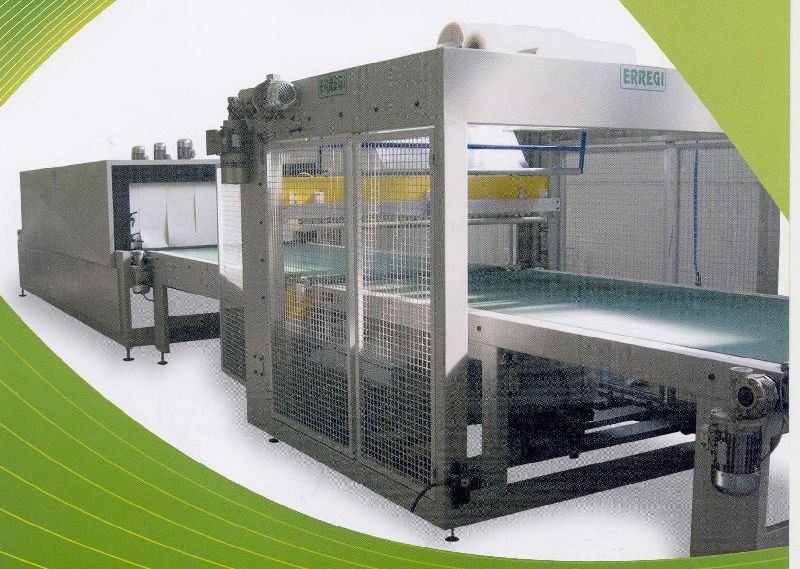

New shrink foil packaging machine

Brand: Erregi

Type: EASY 250

This plant consists of the wrapping machine and the shrink tunnel.

The wrapping machine is formed of a suitably reinforced steel chassis, an infeed and an outfeed conveyor belt.

In machine chassis there are the following components:

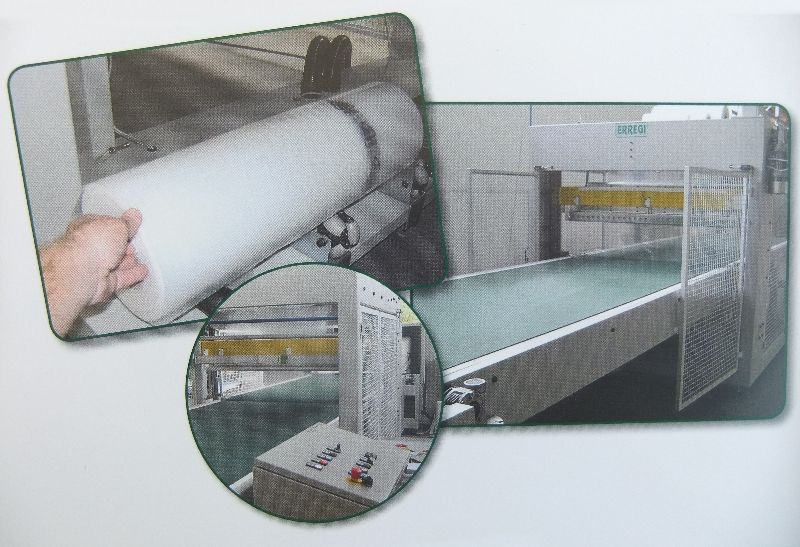

- The driven upper roller

- The system for unrolling the lower roller, consisting of a driven roller and a pneumatic assisted idle roller.

- The system for welding and cutting the upper and lower PE sheets consisting of a special alu profile, with temperature controll and changable steel blade for carry out the cold cut.

- The infeed and outfeed transport belt is likewise made up of reinforced steel chassis on which a closed link belt is mounted.

The shrink tunnel consists of two chassises.

- One holding the heated part and one supporting the former.

- This system with the triple insulation in rock wool avoids heat dispersion and reduces consumption.

- The transport system is composed of a teflon-coated metal mat activated by an adjustable speed motor.

- The strengthened resistance with the centrifugal ventilators distribute the heat even.

- At the tunnel exit there is the edge press unit.

Working cycle:

- The product to be wrapped will be loaded manually or it comes from a previous plant.

- It will be automatically transported and wrapped from above and below.

- When the operation has been completed the welding and the sheet cutting cycle begins at the rear part of the package.

- The wrapped product proceeds towards the tunnel to undergo the shrinking phase.

- The edge pressing sponges at the exits compress the sides of the package.

- There are two switch boards: each for a shrink tunnel and for the wrapping machine

CE regulations.

Wrapping machine EASY 250

- Length of welding bar 2.500 mm

- Amount of upper rollers 1

- Max. width of the upper rollers 2.450 mm

- Amount of lower rollers 1

- Max. width of lower rollers 1.450 mm

- Width of belts 1.300 mm

- Length of outfeed belt 3.000 mm

- Length of infeed belt 3.000 mm

- Max. recommended height 700 mm

- Working height 800 mm

- Min. Workpiece weight 1 kg

- Max. Workpiece weigth 150 kg

Tunnel 700 L

- Power installed 54 kW

- Average consumption 30 kW/h

- Length of shrinking area 3.700 mm

- Length of tunnel 4.700 mm

- Width of conveyor 1.500 mm

- Max. Workpiece height 700 mm

- Working height 800 mm

- Transport speed adjustable 4-20 m/min

Note:

Working speed according to thickness and quality of foil.

- Polymer conveyor

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia