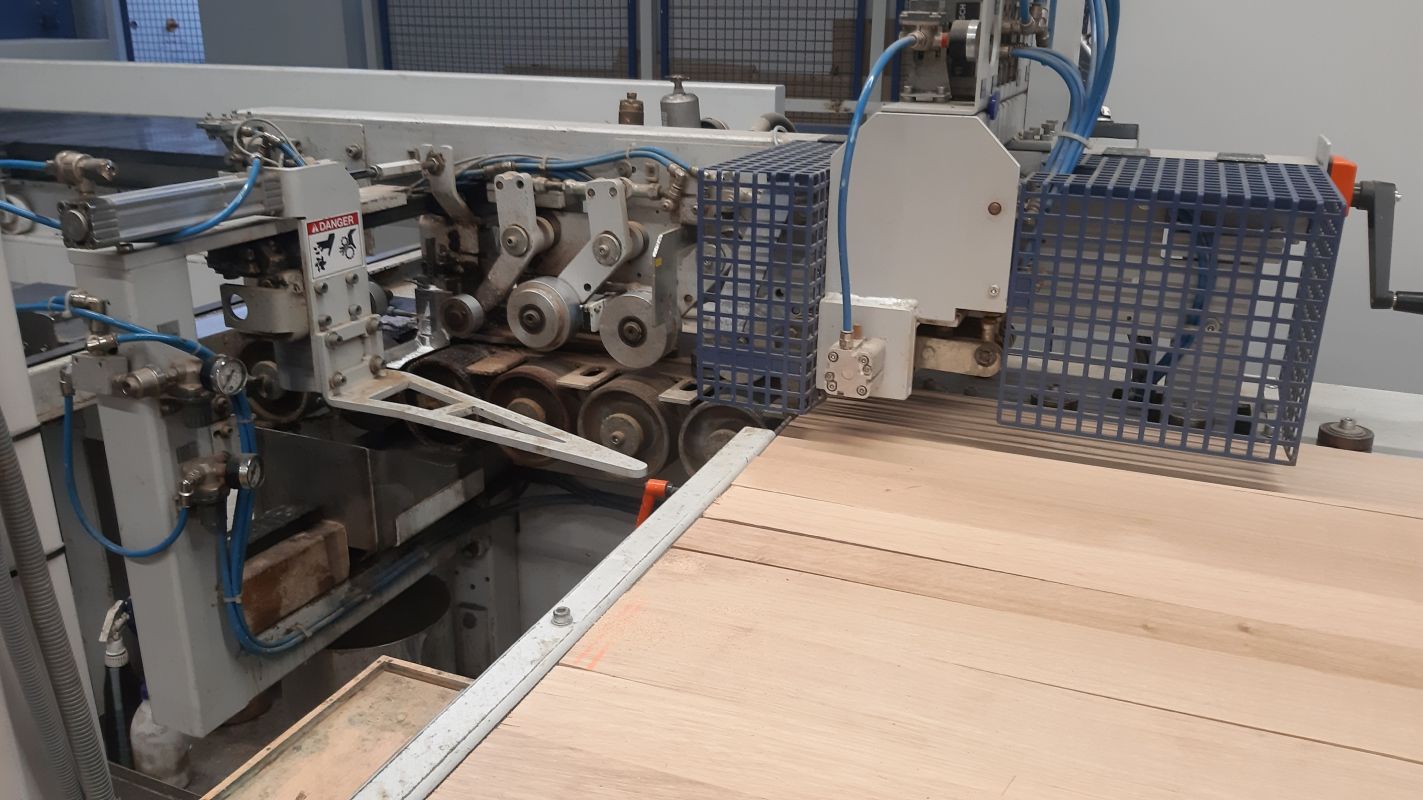

gluing press

Brand: Dimter

Type: PROFIPRESS L2500

Year of manufacture: 2007

Technical data

Wood dimensions to be processed

Wood widths for panels: 30-150 mm

Wood thicknesses: 11-60 mm

Wood input length: 800 - 2500 mm

Panel widths variable: max. 1300 mm

Specific pressing pressure for cross-sections of 2500 x 60 mm up to 1.6 N/mm2

The contact surface per press filling must not be less than 100 cm2

Filling width of the press per cycle: min. 650 mm / max. 1300 mm

Max. filling area of the press per cycle 3.25 m2

(The max. usable press width depends on the widths of the individual lamellas.)

Wood type

Softwood/hardwood

Press without options

Electrical connection value of press: 7 kW

Electrical connection value of 40 kW generator: 56 kW

Operating voltage: approx. 400 volts / 50 Hz (C/s)

Collection table extended to 3700 x 1300 mm, with stainless steel wood support

Motor-driven multifunctional pusher

Profipress L 2500 gluing press

Press bed area approx. 2500 x 1300 mm

Stable base frame with lower press table made of stainless steel as ground electrode

Quick-change stop ruler sets for panel thicknesses from 19 to 40 mm, which can be moved hydraulically to the current filling width

Special hydraulic pressure elements ensure even pressure distribution over the entire joint length and compensate for tolerances

In multi-lane operation, filling widths may vary by a maximum of 15 mm

Upper pressure plate with hydraulic motor anti-reb creates high vertical pressure for low offset

Integrated hydraulic unit for generating the pressing force and driving the hydraulic motors

Control cabinet and control panel

Protective cover

Additional individual pressure elements from above

Automatic gluing station with precision glue head

Feed for different widths

Camera

Washing and rinsing device for glue head

Modem incl. software for online connection

Note:

The technical data and descriptions are copies of the order confirmation at the time. The information is for informational

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia