Profile Wrapping Machine

Manufacturer: Barberán

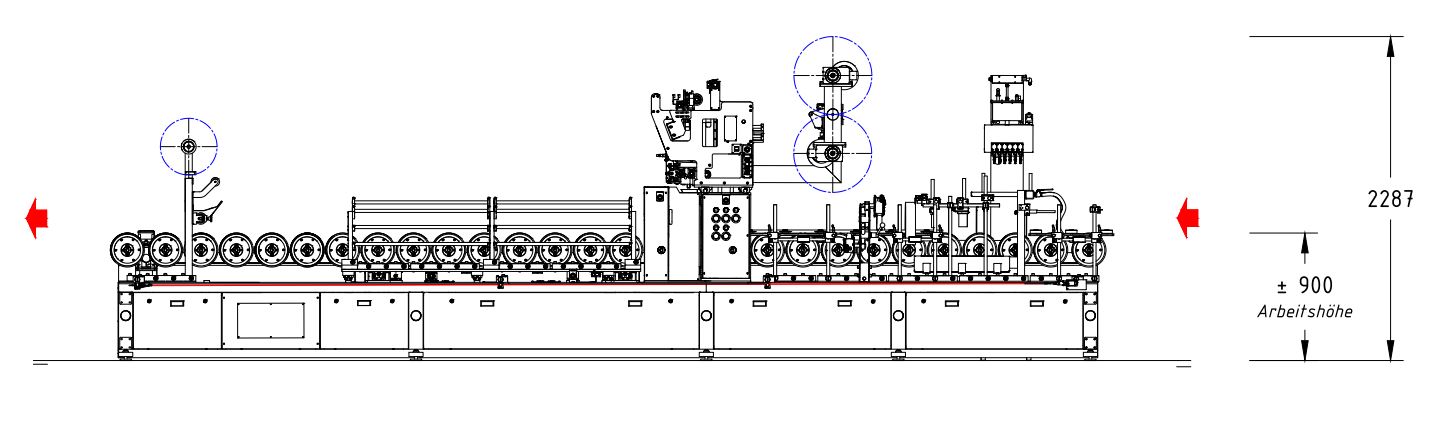

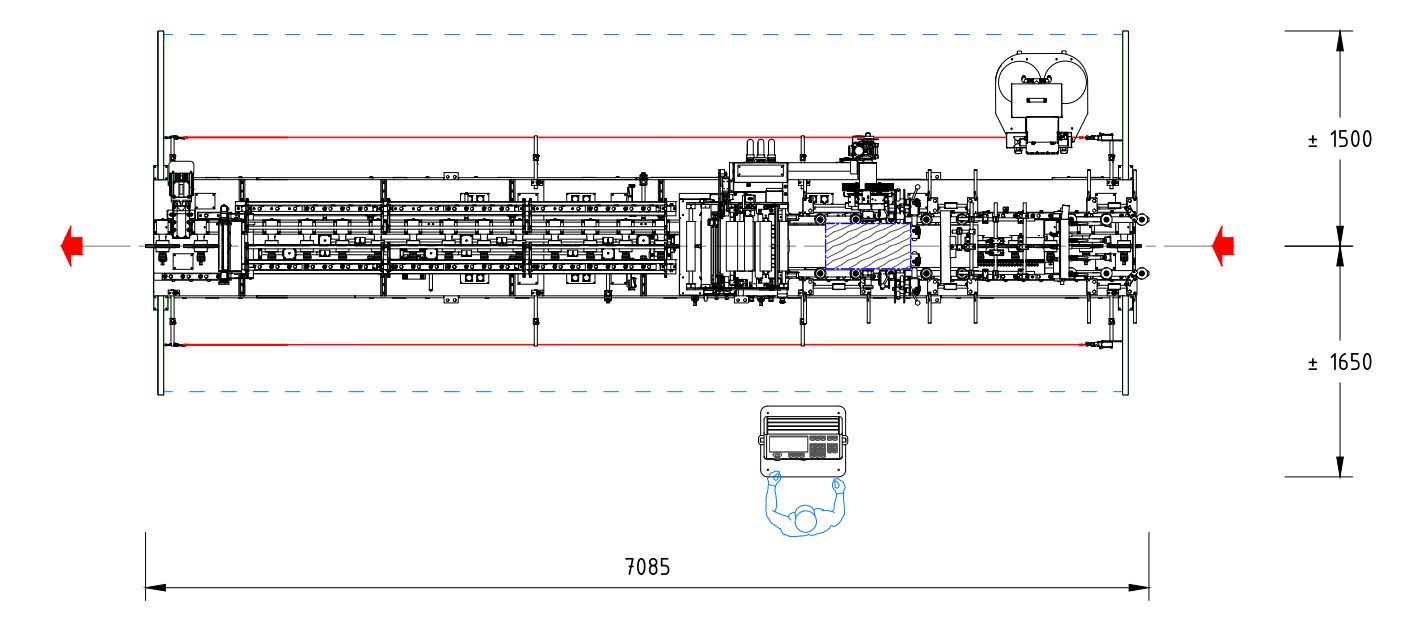

Model: WM-33

New Machine

General Function

The profile wrapping machine or line is designed to wrap profiles of various shapes, sizes, and materials using different foils with hot melt adhesives. The machine can operate as a standalone unit or as part of a complete production line. The machine length depends on the size and shape of the profiles the customer intends to use.

Materials

This machine is capable of working with various materials such as PVC, aluminum, and some composites. Special configurations are required for materials like PVC or aluminum. Barberán must be informed when such profiles are used.

Foils

Various foil types can be used, such as paper, PVC, PP, acrylic, thin CPL, nonwoven-backed veneer from rolls, etc. Some of these require special adhesives or heat treatment. Barberán must be informed of the desired foils to ensure optimal performance.

Adhesives

This profile wrapping machine is designed for the use of market-standard PUR hot melt adhesives. Barberán must be informed about the type of profiles and foils, as well as the desired production capacity, so that a suitable hot melt adhesive unit can be offered.

Technical Specifications

Min/Max Profile Width: 25 – 300 mm

Min Profile Length: 600 mm

Min/Max Profile Height: 4 – 120 mm

Min/Max Foil Width: 25 – 330 mm

Max External Foil Roll Diameter: 600 mm

Inner Roll Diameter: 76 mm

Max Mechanical Speed: 60 m/min*

Total Machine Length: 6,000 mm

Working Height: 900 mm

Operating Side: Left

Voltage: 400V – 50Hz

Compressed Air: 6 bar

Color: RAL7035 + Barberán Blue

*Maximum speed does not equal maximum production output. Output depends on the profile type, adhesive, and foil used.

Standard Configuration Includes:

Machine Entry Section

Heavy-duty steel frame for stability

Transport rollers driven by a motor with frequency converter

Manually adjustable left/right guides for profile entry

Integrated control cabinet with 8 sockets for hot air blowers

Emergency safety barriers on both sides

Two emergency stop buttons (panel & machine)

Glue unit safety mesh

Operator control panel to manage adhesive weight, primer station, and foil splice

Optional PC control system

Transport Rollers

Two 15 mm wide rollers per shaft, 240 mm diameter

Quick positioning in 5 mm steps

Reversible for setup ease

Profile Pre-Treatment

Air Blowers & Ionization

Removes static and dust using ionization barrier and 4 flexible nozzles

Automatic Primer Station

Digitally controlled, precise primer application

Key components:

Diaphragm pump

Circulation and vapor extraction

Filter & distributor

Solenoid valves

Felt applicators with Barberán quick-change system

System Operation

Primer pumped to intermediate tank

Controlled by proportional valve

Solenoid valves dose primer based on g/m² & speed

UV LED Light Barrier

Allows visual inspection of primer application

Heaters

6 standard self-regulating heaters with external turbine (expandable to 8)

Slot Nozzle Head (330 mm)

Electrically heated, mesh-filtered, 1000W

Applies PUR, EVA, APAO adhesives

Adjustable with SIKO counters

Synchronizes with first profile entry

Requires separate glue melt unit

Auto weight control via HMI (g/m²)

Foil Unwinding Station

Roll Ø up to 600 mm

Expandable shaft Ø 150/76 mm

Magnetic powder brake for constant tension

Side-shiftable for foil/profile alignment

Foil Preheating

Infrared screen with adjustable power for foil heating

Profile Wrapping Unit

Foil applied with shaped rubber rollers

Cassette system on both sides with pre-set tools

Horizontal bars enable quick profile shape change

Protective Foil Unwinder

30 mm shaft for foil rolls Ø up to 600 mm

Height-adjustable pressure roller for protective foil

Included Components

1x Machine bed (6,000 mm)

1x Slot nozzle head (330 mm)

Adjustable laminating lip

Filtered & teflon-coated

2 handwheels with digital readouts

Teflon scraper with handle included

Note: Requires separate heating hose & melt pump

1x Mounts for Wrapping Tools

1x Complete Tool Set for PVC/Aluminum Profiles

(Includes 100+ wheels, shafts, bolts, washers, mounting brackets – detailed specs omitted for brevity)

2x Stainless Steel Entry Guides (WM-33)

1x Stand & Dual Unwinder for Glue Head (330 mm)

1x Operator Safety System (CE Compliant)

1x Control Cabinet and Panel

1x Set of 4 Nozzles for Profile Cleaning

1x Protective Foil Unwinder (Ø 76 mm shaft)

6x LHS-211 Heaters for Adhesive Activation

Controlled via PLC

Requires blower turbine (Option 0060/0706)

May need 380V–220V transformer (Option 0707) if no neutral phase is available

2x Central Hot Air Turbines

Medium pressure, 0.85 kW motor

4 valves and connectors for hot air blowers

1x IR Screen with Two Short-Wave Lamps (3 kW each)

1x Split Tool Cassette (2 meters)

Two 1-meter sections with quick-change bars

16 bars (1 m), 32 discounted bars (540 mm) included

Note: Wrapping molds not included

1x Tool Set (36 Wrapping Tools)

(Details similar to earlier tool set, includes various wheels, shafts, clamps)

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia