BrandSALVADOR

typeSuperpush 200

stateNew

stock number1110243

Raw lengths 500 – 4,100 mm

Safe loading with the 30-degree tilted table

Convenient Windows control on a 22" LED color display

Scanner system for defects of all workpiece thicknesses

Questions about this machine

Optimizing Crosscut Saw

Manufacturer: Salvador

Model: SUPERPUSH 200

New Machine

Highlights!

Special inclined surface with a 30° angle

Pusher with automatic lift during scanning

Computer + numerical control

Software for Windows environment

Total Optic System

Intelligent clamping

Two automatic alignment pushers

Rear safety cover

The SUPERPUSH 200 was developed as a direct technological evolution of conventional cutting methods. It increases productivity, minimizes manpower needs, and improves wood yield.

EXTREMELY ROBUST

The frame is made of thick, reinforced, painted steel.

Special support surface with a 30° incline to facilitate loading and keep the workpiece square.

Pusher slide holder: 300 x 345 x 25 mm.

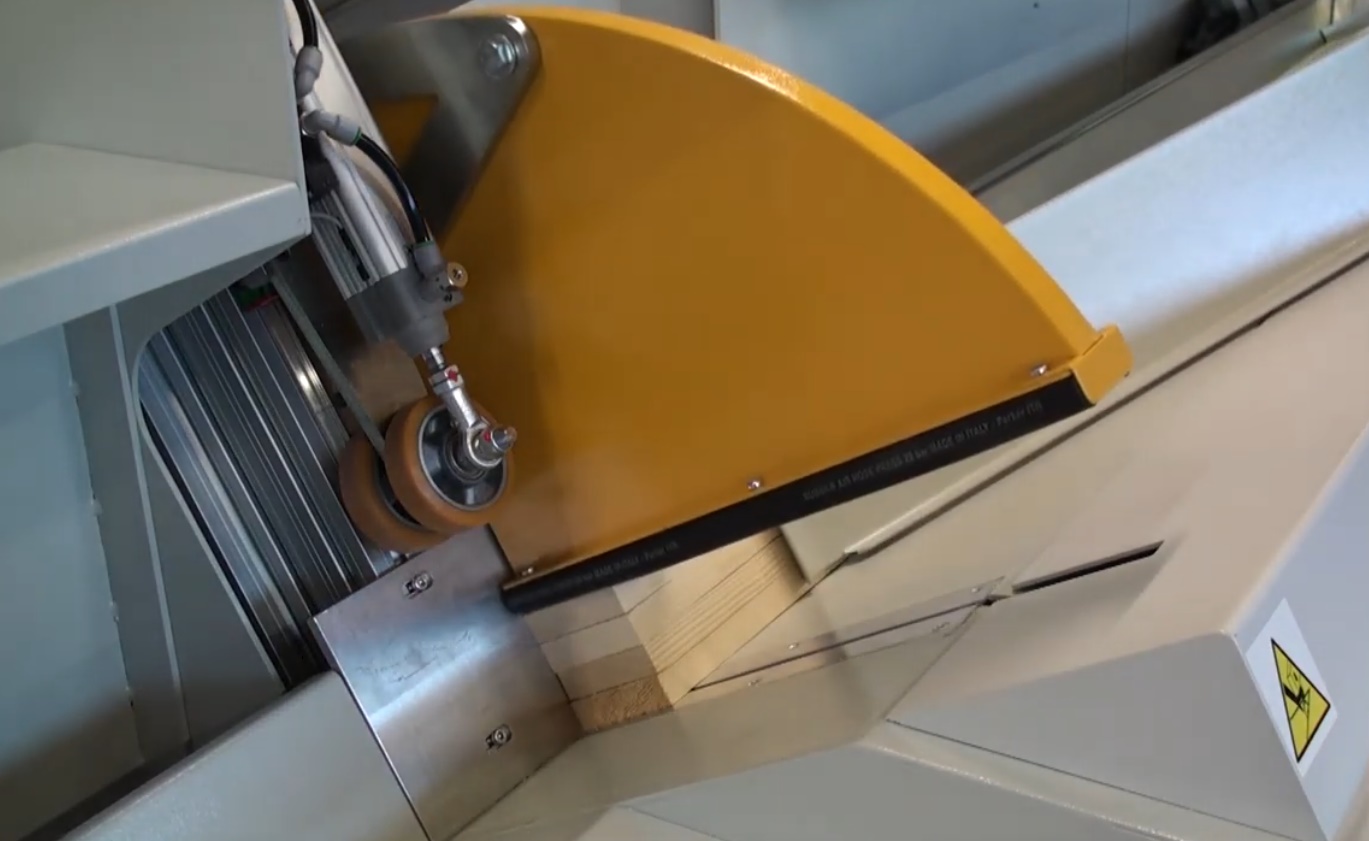

50 mm wide toothed belt with 33 steel inserts.

Horizontal, continuous workpiece marking and support surface, 300 mm wide.

TECHNOLOGICALLY INNOVATIVE

The electronic system consists of a computer in real-time communication with a modern computer-aided CNC (numerical control).

Windows-based software.

Supports management of 5 different quality grades.

22" LED color display.

Includes remote maintenance via internet + Excel macro integration.

FAST

Complete optical system.

Brushless servo drive for electronically controlled feed.

Intelligent clamping.

Adjustable cutting speed.

RELIABLE AND SAFE

Drive system glides on hardened and calibrated dual guides.

SKF linear guides with double dust protection and automatic lubrication.

Separate and self-supporting control cabinet.

Independent pneumatic adjustments for various processing types.

Rear safety cover for maximum protection.

[/b]TECHNICAL DATA[/b]

CUTTING DIMENSIONS

Board length before cutting: max. 4100 mm, min. 500 mm

Cutting cross-section: max. 240x150 / 300x110 mm, min. 30 x 15 mm

Only one cut is possible in the last 40 mm of the board

Max wood weight: 50 kg

STANDARD EQUIPMENT

FEEDING & PUSHER

Pusher with new technology, innovative lifting mechanisms, safety features, and Total Optic System.

Feed motion controlled by computer and CNC.

Structure made from thick, reinforced, painted steel.

Special inclined support surface (30°) for easier loading and squaring.

Horizontal, continuous workpiece support table, 300 mm wide, table height: 1000 mm.

Rear protective cover for safety.

According to safety standards, max feed speed can be set to 60 m/min, depending on wood dimensions and optional downstream sorter.

PUSHING SYSTEM

Large and strong pusher slide (300 x 345 x 25 mm) handles high loads and torque.

High-precision pushing system using a 50 mm wide toothed belt with 33 steel inserts, robust dual-guide system (dustproof, low maintenance, long service life, excellent reliability).

Aluminum support frame (120 x 135 mm) mounted on solid steel.

Aluminum surface covered with wear-resistant steel for easy wood sliding and reduced wear.

Brushless DC servo drive motor for electronically controlled, constant torque feed. Motor mounted in pulling position at the front.

Removable aluminum pusher plate: 100 x 135 mm.

TOTAL OPTIC SYSTEM

Integrated scanning system with a laser light barrier for wood detection and a special luminescence scanner for reading markings.

The system is fixed and requires no manual adjustment when wood thickness changes.

CUTTING UNIT

Inclined cutting plane (30°).

Structure made from very robust thick steel plates and tubing.

Saw motor power: 7.5 HP (5.5 kW)

Cutting time adjustable via computer from 0.1 to 2 seconds

Cutting speed adjustable via pneumatic regulator

Steel safety covers for maximum stability

Upper pneumatic clamping with electro-pneumatic control.

Intelligent clamping: Automatic lift height adapts to different wood thicknesses, reducing lift distance and cutting times.

Clamping system runs on new SKF ball-bearing guides with dual dust protection and automatic lubrication.

Aluminum saw blade guides, easily replaceable.

The system can be adapted to various applications using several independent pneumatic adjustments.

Solid machine anchoring with flanged steel feet.

Saw blade:

Type: Carbide-tipped circular saw

Diameter: 500 mm

Teeth: Z=108

Bore: 35 mm

Sawing area lighting for easy inspection and cleaning

Two adjustable blade lift speed regulators

TWO ELECTROPNEUMATIC ALIGNERS

Two electropneumatic aligners (before and after the saw blade) ensure square cuts and align the workpiece on the pusher.

The first aligner moves horizontally to press the workpiece closer to the fence and improve accuracy during braking.

The second aligner operates vertically to ensure precise acceleration and deceleration.

Independently computer-controlled with safety systems.

ELECTRONIC SYSTEM: PC WITH BUILT-IN CNC SOFTWARE

Computer with optimization algorithm software based on Linux, user interface runs in a virtual Windows environment.

PC

Windows-based interface (custom version based on Windows 10)

Intuitive and efficient S4U software

Easy parameter setup

Extensive customization and prioritization for optimization

Detailed cutting statistics, simulation features, real-time updates, error detection

Extremely fast calculation: performs all optimization combinations in just 2 milliseconds

Manages up to 5 quality grades

Stores hundreds of thousands of programs

22" LED color display in ideal viewing and programming position

Dust-protected full-size keyboard with mouse (pull-out tray)

External USB port

Includes Excel macro data import and ASCII format compatibility

Remote maintenance software pre-installed

Shock-proof, dust-proof computer with recovery copy

Maximum computing performance and reliability

CNC SYSTEM

High-performance CNC that communicates with the dual-axis computer for scanning wood, measuring, and optionally sorting.

Features advanced processors and boards for optimal speed and performance.

CONTROL CABINET

Separate and self-supporting

Transport-, dust-, and vibration-proof

Thermostat-controlled ventilation

Positioned for optimal cable routing and minimal electrical interference

External digital I/O interface with modular, interchangeable EtherCAT modules

Operator control unit placed for optimal access during loading

Start button in ergonomic position

UPS (Uninterruptible Power Supply) ensures smooth operation during voltage fluctuations or short power outages. Also helpful in case of improper shutdown.

OUTFEED TABLE

Made of solid steel

Length: 3000 mm

30° incline like the rest of the system

Includes guide rail

Simplifies removal of finished parts

Note: These specifications are examples. Contact us for consultation and a custom-tailored offer.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia