BrandHOMAG

typeOPTIMAT BAZ222/60/K

stateUsed

Price (plus VAT.)€ 48000

stock number0031125

year2010

with gluing unit

Workpiece lengths max: 6.175 mm

main spindel 15 KW

tool changer 18-fold

boring head 30 spindles

additional milling spindel 6 KW

FLEX-5 unit

Price: 48.000,00 EUR

Questions about this machine

Used CNC-processing centre

Brand: HOMAG

Type: OPTIMAT BAZ222/60/K

Year: 2010

with gluing unit

with FLEX-5unit

Workpiece length max:

- All units: singe field 6.000mm, pendular process 2.375mm,

- At tool-Ø 25mm: 6.175mm, pendular 2550mm

Workpiece width max.

frontal:

- All units 1150mm,

- At milling process with tool-diam. 25 mm: 1220mm*,

- At edge banding: 1220mm*

* at workpiece thickness max. 40 mm

rear:

- All units 1400mm,

- At milling process with tool-Ø 25 mm: 1550mm,

- At egde banding 1475mm

- with standard flush milling and gluing 1500mm

Workpiece thickness:

- Max. 300 mm inclusive chuck at use as top miller

- Up to max. 60 mm with standard clamping without limits for units and suction

- Min. 12 mm at chamfer milling

- Min. 16 mm at radius millers or min. 2 x Radius + 10 mm

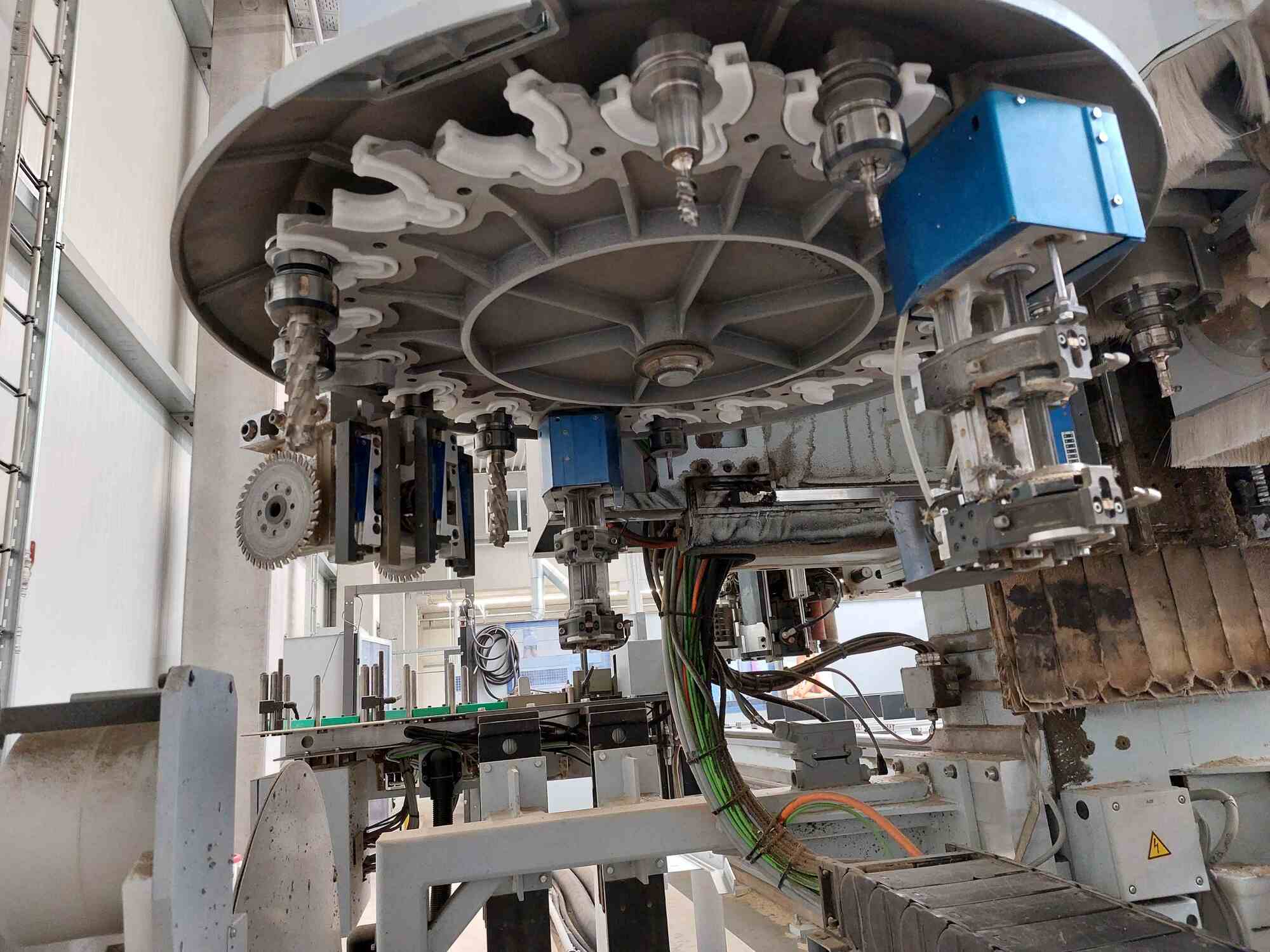

Main spindle 15 KW, HSK F63

C-Axis with unit interface

Plate changer 18-fold D=130

- Tool weight max. 6 kg

incl. holding for max. 10 kg units

Drilling head 30 spindles: V20 / H10/ S360° "MPU"

- 1 Motor 2,7 kW, frequency changed

- Rotation speed max. 7500 1/min

20 verticale spindles High-Speed:

- Spindle order in U-Form

- 3 rows of drillers with 11, 3 und 6 spindles

10 horizontal spindles:

- Order of spindles in pairs

- 4 pairs of drilling spindles, grid 32 mm

- 1 pair of drilling spindles, distance 320 mm

Groove saw: blade-Ø. : 200 mm

Adaptive milling spindle 6 KW for drilling head

- 6 KW at S6 operation

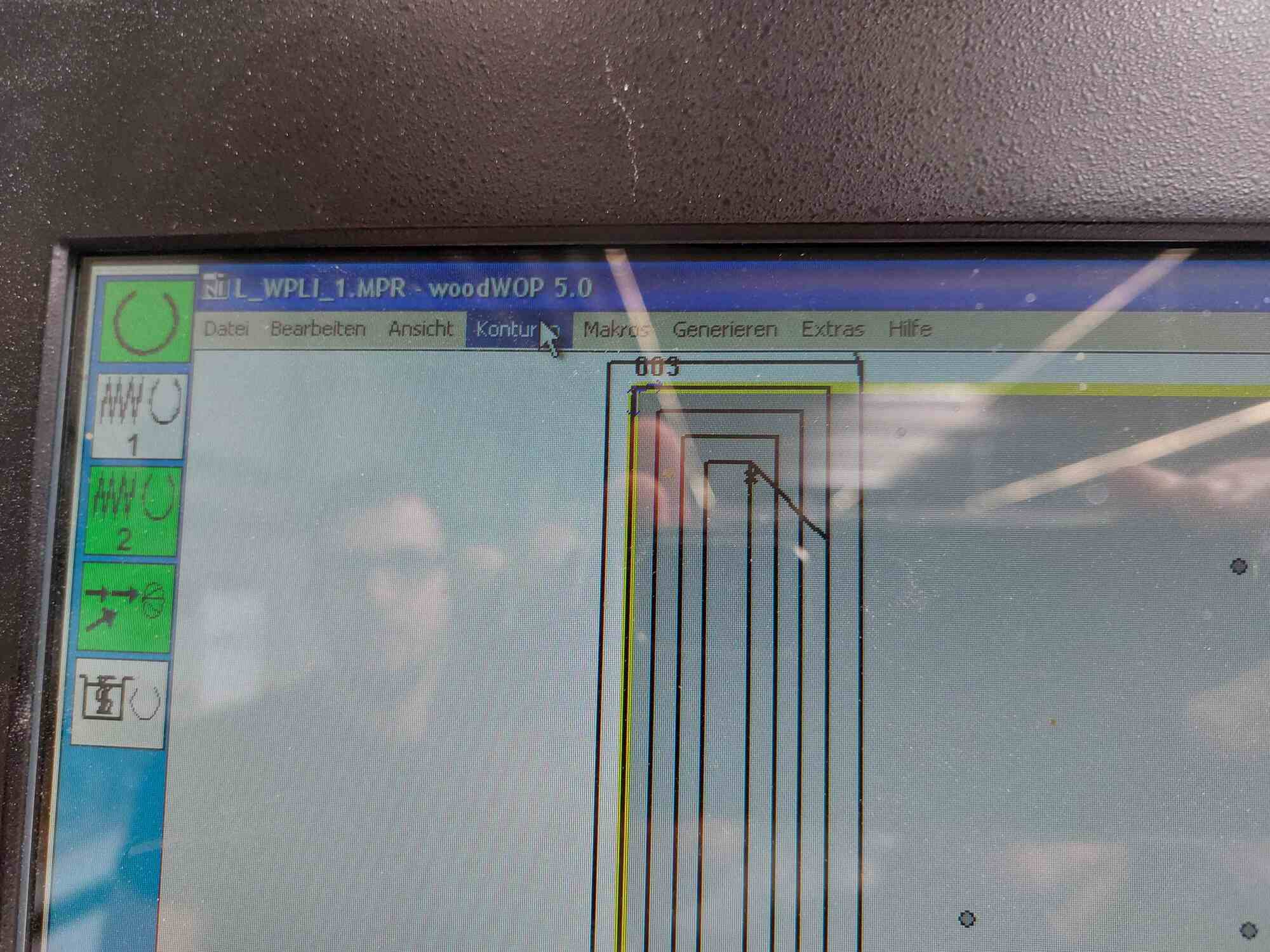

FLEX-5 unit

C-axis prepared for FLEX-5 unit

- coupling element

Gluing unit POWER EDGE:

- for edge material (rectangular cross sectional area) on straight workpiece edges

- Gluing unit for 360°-gluing with butt joint

Edge height 105 mm for gluing unit BAZ222/322

allows edging of workpieces up to 100 mm workpiece thickness

Flush milling unit for tool changer

Combi-flush milling-scraping unit WD 100 MM

Combi- end trimming and copying unit., traced

Lock recess milling unit 2 spindles D=16/20

Chip transport belt for B200/52-72

LED-setup support console 1300-1600 mm

without tools

Note:

The specifications and descriptions are a copy of the order confirmation at that time. Data are for information and are not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia