BrandVITAP

typeK3

stateNew

stock number1010117

- new machine -

- Interruption-free workpiece transport

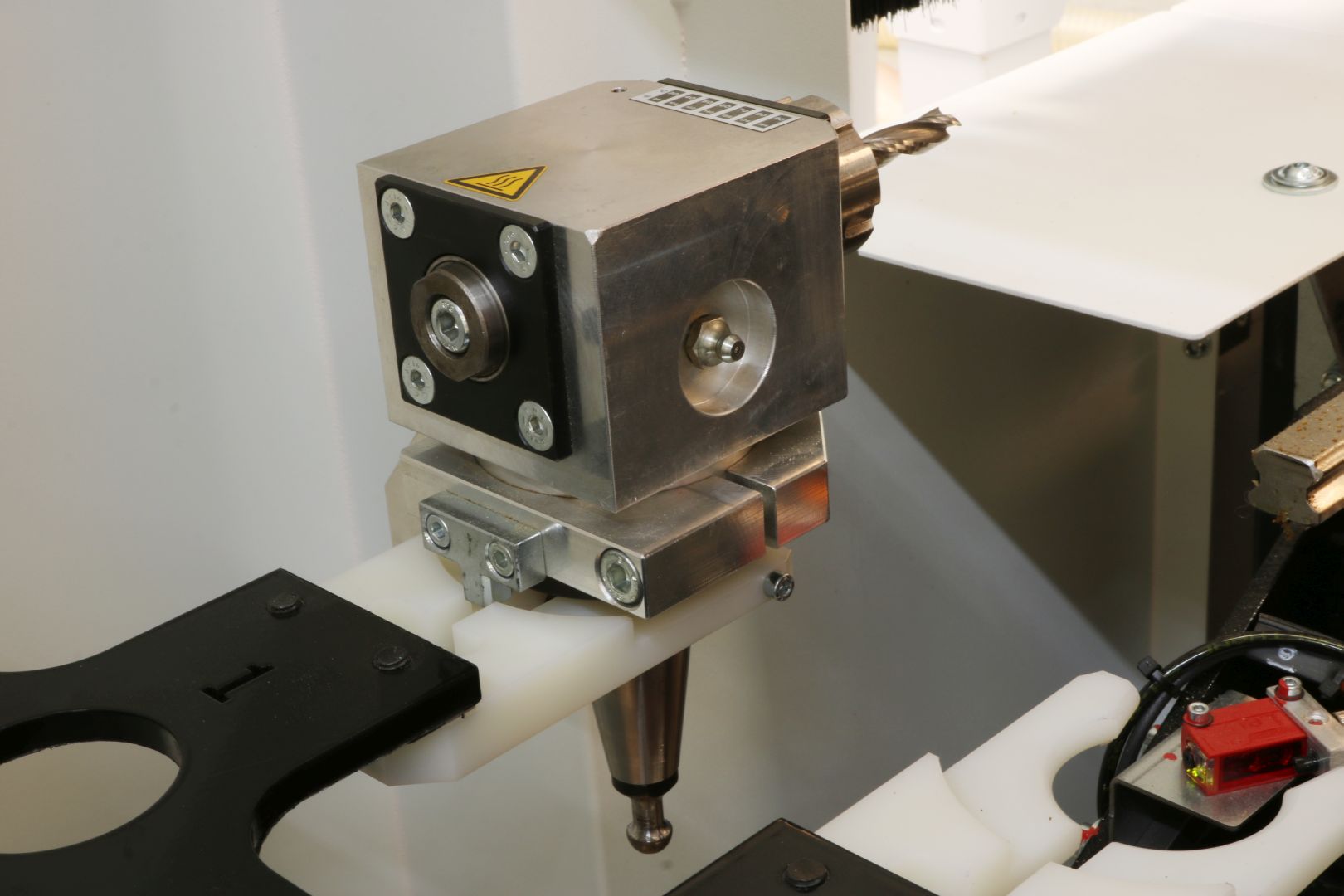

- Automatic 4-fold tool changer

- No workpiece length limit and 1250 mm working width

- Optionally with loading and destacking

Questions about this machine

CNC boring- routering machine

Brand: Vitap

Type: K3

New machine

Throughfeed process from the bottom and automatic panel return to the operator.

Develop a new individual class:

- With this machine you can do grooves and drill processings as well as different milling works, from simple edge milling to the milling of forms and letters.

- There are no limits for your creativity

Easy beginn with CNC programming:

- TPA makes it easy: drillings, grooves, linear millings, form millings or the millings of letters

- The CAD Software shows the processings on a virtual workpiece

- Good overview about all processings on the single sides of the workpieces

- Mirror function for parallel processings on other positions

- Choose reference points via entering the exact position or just via click on the virtual workpiece

Vitap Bar Nesting - efficient and time saving

- This patented Software processes whole corpus elements out of one longer workpiece.

- Just insert the workpiece and when you take the first finished element, the machine contues with the processing of the next element.

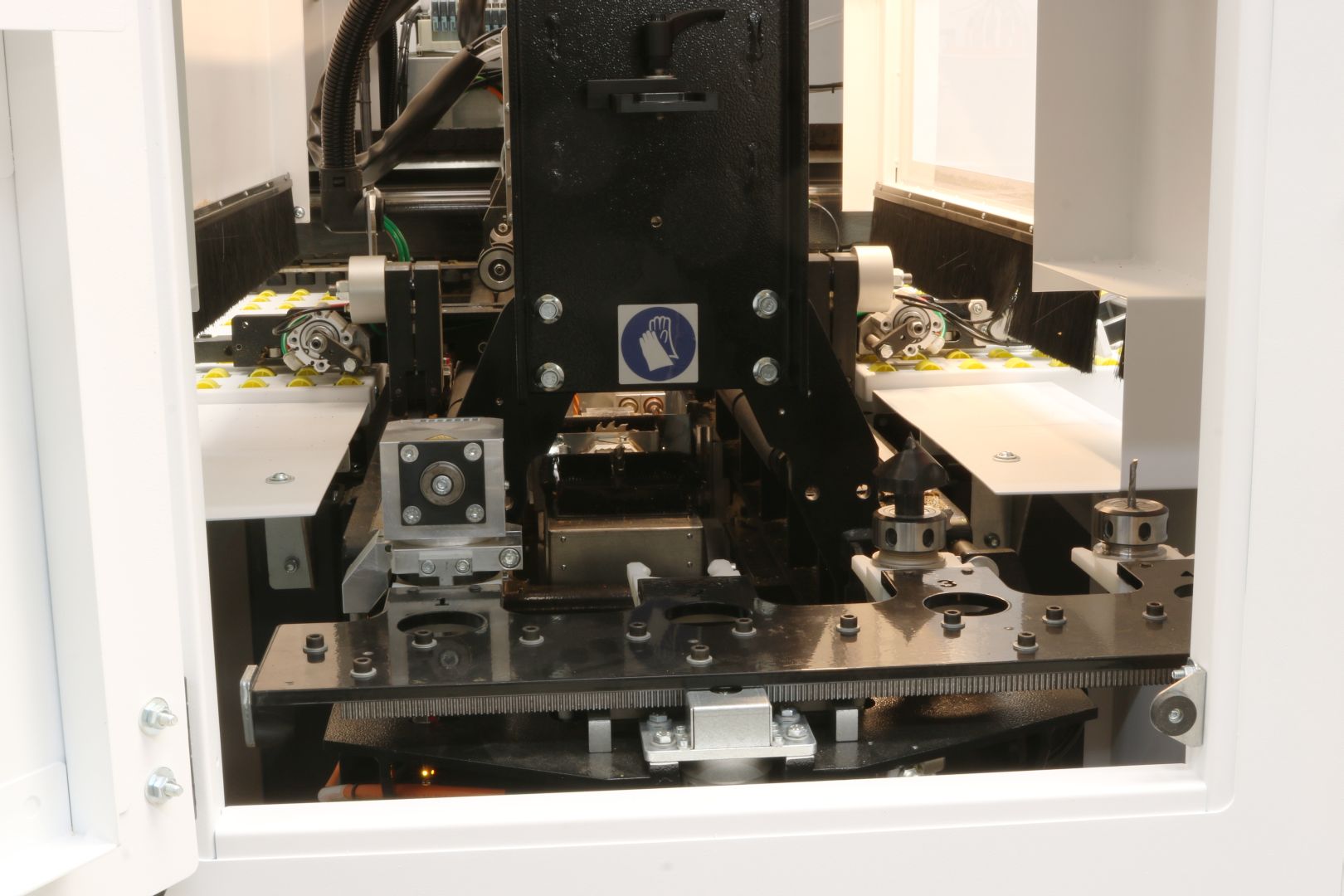

The DDT-feeding sytem (double dynamic transport)

- 2 Clamps make the interruption free workpiece transport possible.

- The operator insert the workpiece to the stop.

- Then the 2 clamps take the workpiece and position it absolutely exactly.

- During the process both clamps are communicating, so clamp 2 closes before clamp 1 opens.

- This is why the feed is continous at linear millings as well

- 3 controlled axes

- X-axis - DDT Feed

- Y-axis - Driling head movement

- Z-Axis: Operation depth

STANDARD DOUBLE “0” PANEL REFERENCE:

- New generation laser to detect the beginning and the end of the piece. The program can readjust the drilling at the bottom of the piece to have a perfect flush between the vertical and horizontal pieces. The laser is composed by a transmitter and receiver to avoid any error caused by dark colours of the edge band.

- New system for calibration: 0-3mm on the 4 sides of the panel by shifting the right reference rule

- 2 side fences with roller (1 fix and 1 movable fence), mechanical-digital readout with autom. positioning for the 0-refefence-fence for a remove up to 3 mm on the 0-reference line

- Automatic 4- fold changer

- Adjustable 0-point

- Industrial PC for high programming performance

- Simple programming

- LCD TFT monitor 20"

- USB port

- Cutting optimization Software

- CAD for graphic programming TPA CAD in the basic version

- Storage of all files with all data

- Macro programming

- DXF file import

- Full digital parametric control

Technical data:

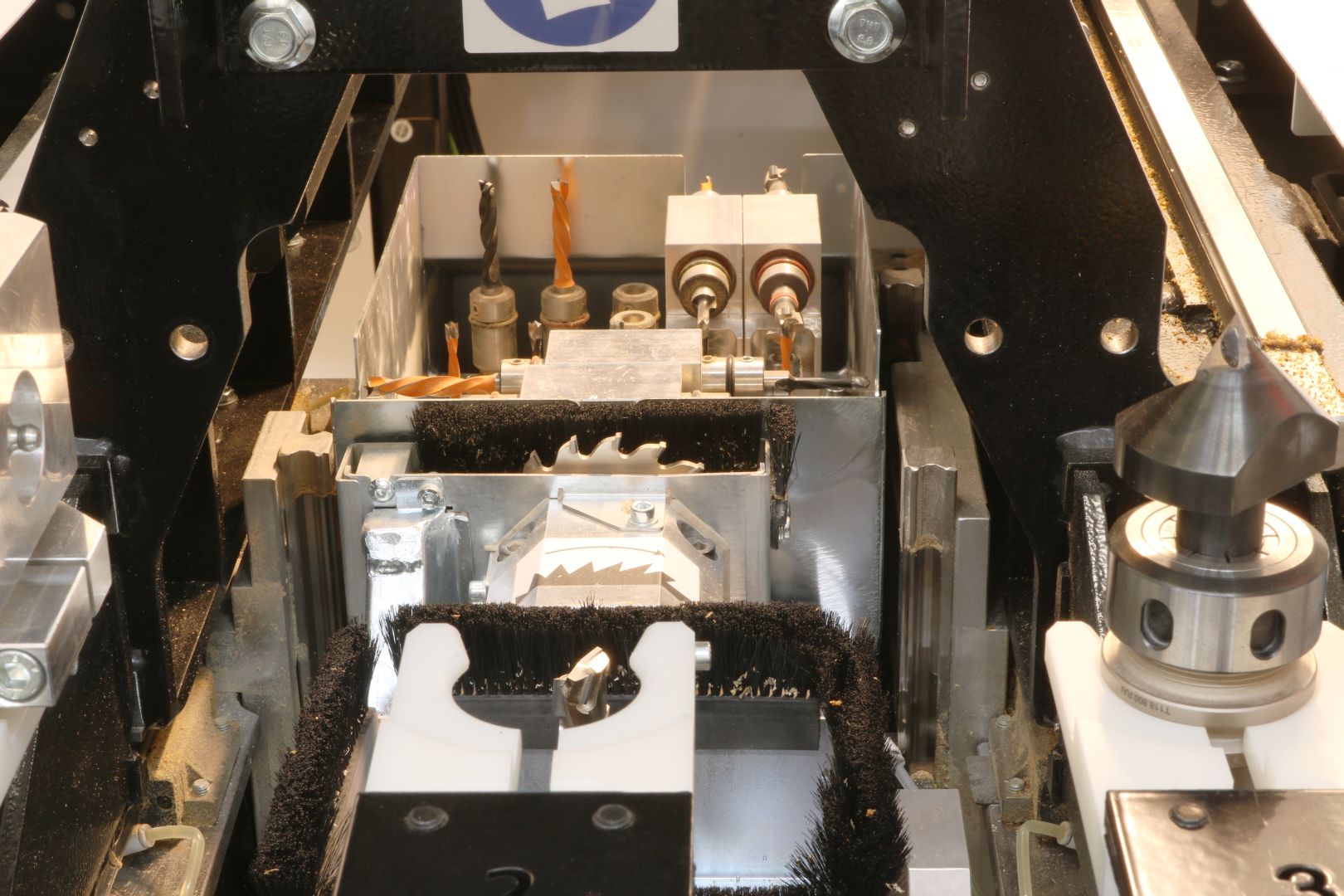

- Number of vertical independent spindles: n°12

- Number of horizontal spindles on X axis: n°(2+2)

- Number of horizontal spindles for drilling on Y axis: n°(2 + 2)

- N°1 saw blade unit (diameter 100mm)

- N° 1 Electrospindle 5 kw with ISO30 cone (rpm12000- 24000)

- Max panel weight: 40 Kg

- Max panel size: X no limit, Y 1250 mm, Z 50mm

- Min. panel size: X 270, Y 150 (70 op), Z 3 mm

- Panel feeding speed: 25m/min

- Spindles rotation speed: 3600 rpm

- Saw rotation speed: 7000 rpm

- Max horizontal diameter of the tools 12mm

- Max drilling depth in vertical: 43 mm

- Max vertical diameter of the tools 35mm

- Motor power: 1,7 kw

CE STANDARDS

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia