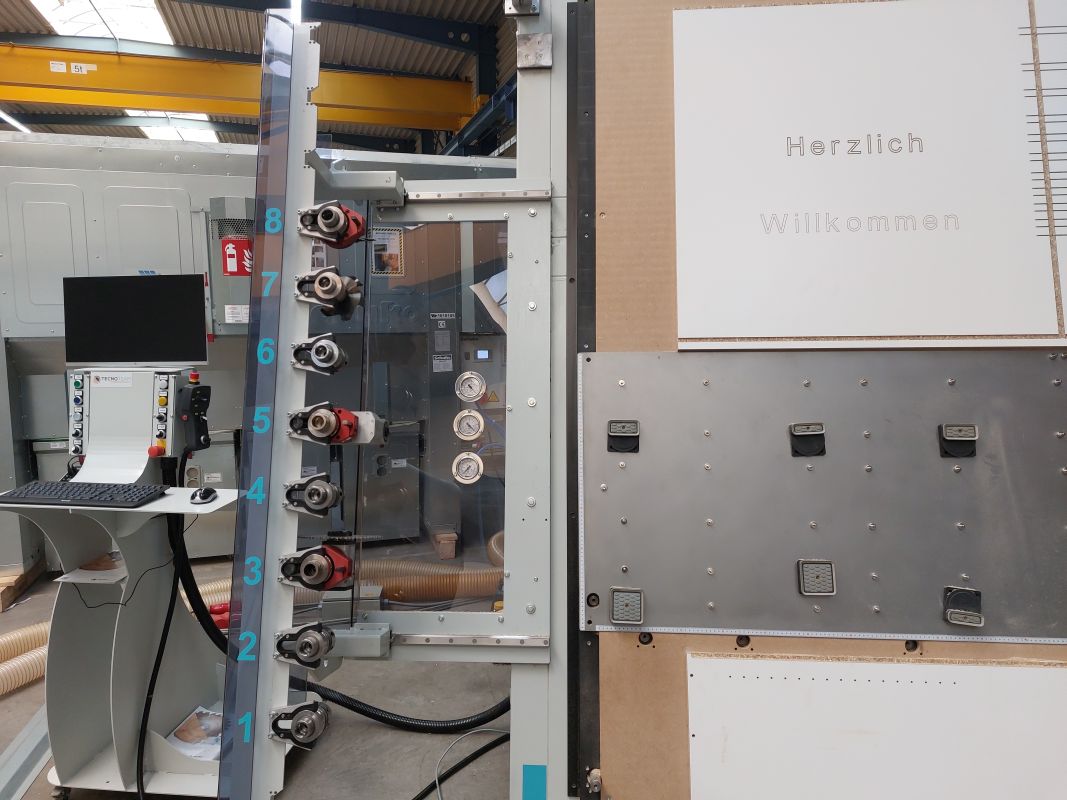

Vertical CNC machine, 3 axes

Brand TecnoTeam

Type: Easy Nest 3021

New machine

Year:2024

The machine concept:

CNC:

Half-size panels (2800x2070) are positioned on the machine table

positioned on the right.

The machine drills and mills all carcass parts; separates them and finished

finished elements can be removed. Cutting to size; transportation to

to another machine.

Individual parts to be drilled/milled can be positioned on the left center of the

center support and can be individually CNC processed.

Sawing:

Individual horizontal/vertical cuts can be made left-centered.

centered on the left. The angle is irrelevant. Larger panels can be positioned individually

positioned at the bottom right and cut to size there.

Technical data:[7u]

Working range X axis: 3000mm -Working range Y axis: 2100mm

Working range Z axis: 100mm

X / Y axis speed: 25M/min

Z axis speed: 13M/min

Automatic vacuum nesting table with 12 zones

Vacuum pump “GEV” m3/h 200

Bearings / ball screws / linear guides

N° 4 bearings in X axis

N° 4 bearings in Y axis

Linear guides H30 e H25 Axes / Motors / Drive cards

Brushless drive motors / High quality encoders

Axis motors with gearbox and virtually backlash-free. Between 5' and 3'

High-precision screw / rack with pinion in X

Screw in Y and Z with zero backlash

MILLER HSD ES929 // 4 pole

Pneumatic opening HSK63F

Main spindle Power KW 5.5 / 9

Adjustable main spindle revolutions UM 3000 / 22,000

Main spindle cooling by fan

Inverter power 5.5 / 7.5 KW

Automatic tool changer

Automatic tool changer with 4 tool changing stations

2 zero points

Zero point “A” bottom right for large panels

Zero point “B” left center support for single panels (option)

Tool length measurement

Automatic measurement of the tool length increases safety

Safety device

Photocell (standard) or bumper (option)

or radar (this raises the machine by approx. 15 cm) (options)

Delivery in split height possible (option)

The machine frame is cut in half approx. 2/3-1/3 for easy

insertion through low doors/gates

The traversing beam is supplied separately

Assembly takes place at the installation site (forklift required)

[u]Software and hardware:

PC Windows 10 current version

Lcd 24” hardware PC HP

Keyboard and optical mouse

DVD drive read and write

Network card for internet connection and remote maintenance

Software Cad-Cam Tpa CAD parametric version Professional

Software “Wood System Control” as lists for running programs.

Free online software for best remote maintenance.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia