BrandMASTERWOOD

typeMasterDrill TF 600 SA

stateUsed

stock number0401719

year2020

- Year of manufacture 2020

- Milling spindle 2x3.5 kW

- upper and lower drilling heads

- Grooving saw

- Barcode reader

Questions about this machine

used processing center

brand: Masterwood

Type: MasterDrill TF 600 SA

Year: 2020

With the TF 600 SA processing center, panels of different sizes can be processed one after the other from all 6 sides without interruption.

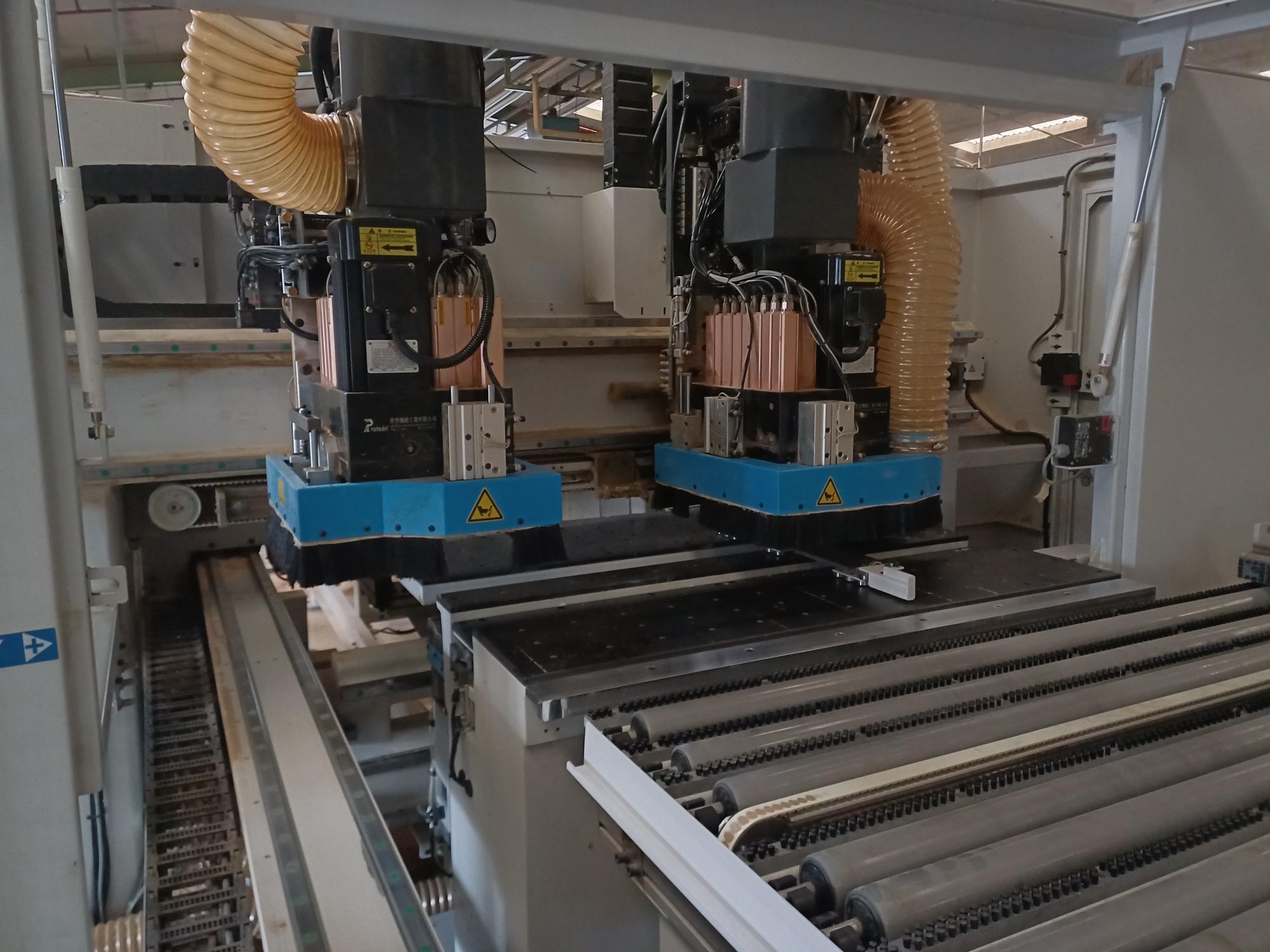

The workpieces are transported along the X-axis by means of two independent grippers. The grippers are NC-controlled and also serve as a reference stop for aligning the workpieces. They are also equipped with a device for automatically measuring the workpiece thickness. Max. Feed speed of the grippers: 130 m/min.

Minimum and maximum workpiece dimensions:

- Workpiece thickness: 8~ 60 mm

- Workpiece length: 400 ~ 2500 mm

- Workpiece width: 400 ~ 950 mm

Drilling heads:

- The drilling heads are made in one casting of aluminum alloy. Two drill heads machine the workpiece from above, one from below. This drilling head arrangement makes the TF 600 SA a versatile machine with high drilling dynamics.

Upper drilling heads:

- Vertical drills in X direction: 7+7

- Vertical drills in Y direction: 5+5

- Horizontal drills in X direction: 2x2 + 2+2

- Horizontal drills in Y direction: 2+2

lower drill head:

- vertical drills: 3x3

Grooving saw:

- A grooving saw mounted on the upper drill head close to the stop enables grooving in the X direction (maximum diameter of the saw blade = 125 mm). Grooves can be cut from a minimum of 55 mm to a maximum of 850 mm.

Milling spindle 2x3.5 kW:

Technical data:

- Maximum power: 3.5 kW

- Maximum speed: 18,000 rpm

- Right-left rotation

- Actuation by means of inverter

- ER 25 tool holder

- Air cooling

The positioning accuracy of the units is +/- 1/10 mm

Automatic workpiece unloading:

Motorized conveyor belt with sensor control.

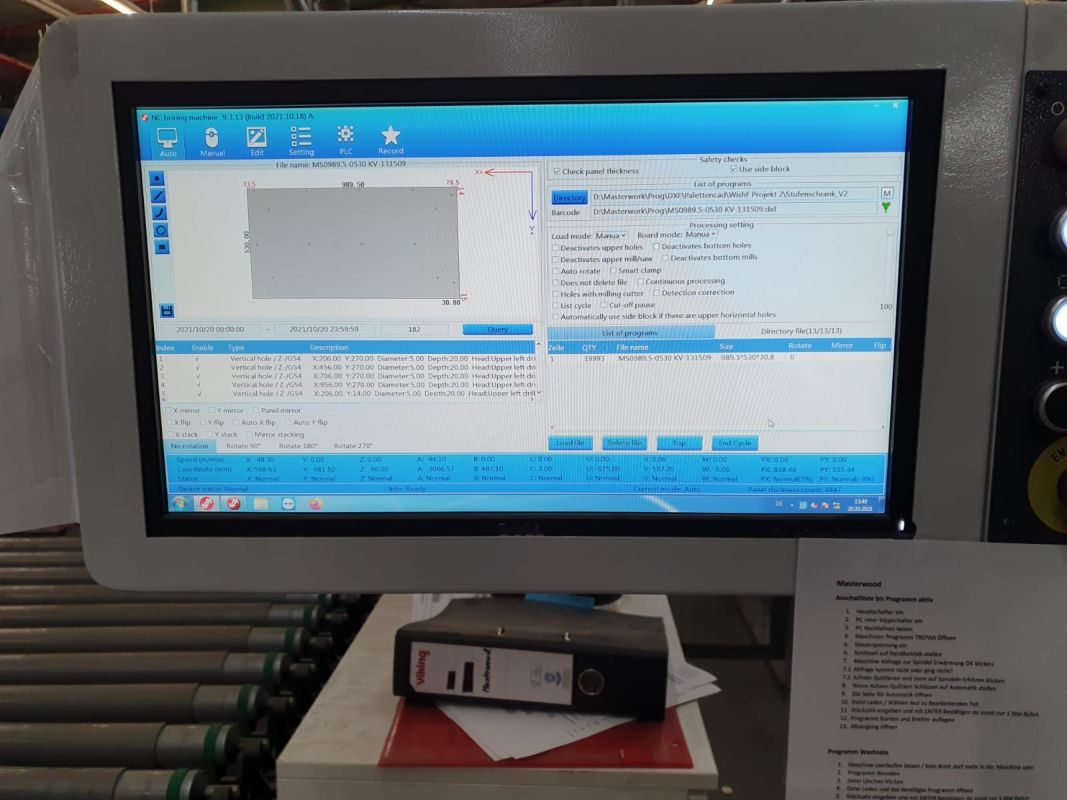

CNC and software:

- The machine worktable is fully managed by NC and guarantees continuous fixing of the panels in all working positions. All movements in the widest possible support surface on the workpiece. Clamping devices are activated depending on the work unit.

The worktable is equipped with an NC-controlled side aligner that ensures perfect alignment of the workpiece panel.

Masterwork:

- Masterwork enables the machine operator to program quickly and easily. The software can import the most important data formats such as DCF and XML.

Master Drill: Man-machine interface for managing operational activities (maintenance/equipment).

Trepan: An interface used by the operator for manual and equipment operations.

Barcode reader:

- Motorized roller conveyor for loading workpieces in the infeed.

- Palette CAM start software for Masterwood TF 600 SA

- Automatic barcode scanner in the infeed

Note:

The technical data and descriptions are copied from the original order confirmation. Data is for information purposes only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia