BrandSCM

typeStefani MD RM

stateUsed

stock number0401718

year2022

- Edge thickness up to 15 mm

- Use of EVA and PUR glue

- with joint milling

- with “Round SK” rounding unit

- with workpiece return

Questions about this machine

used industrial automatic edge banding machine

brand: SCM

type: Stefani MD RM

Year: 2022

General features:

- Adjustable feed speed chain: 10-22 m/min

- Thickness of the strip edge: 0.3-15 mm

- Thickness of the roller edge: 0.3-3 mm

- Max. Feed speed with solid wood edges > 6 mm: 12 m/min

- Max. Roll diameter: 780 mm

Working units:

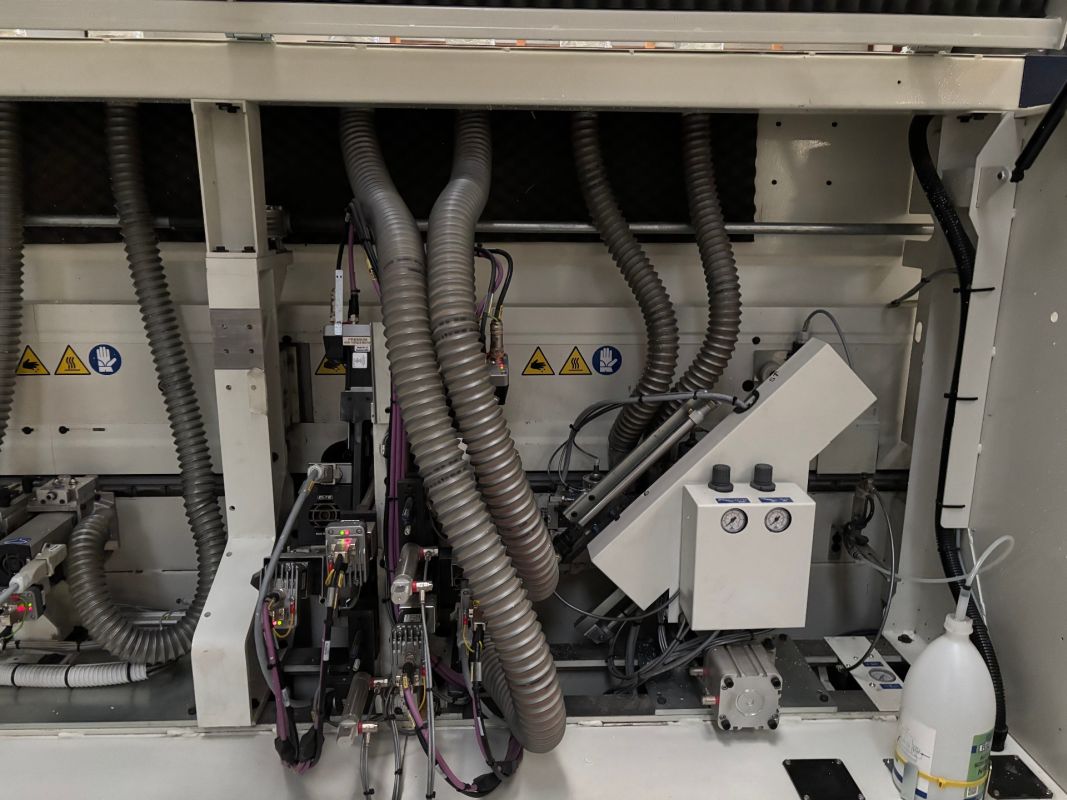

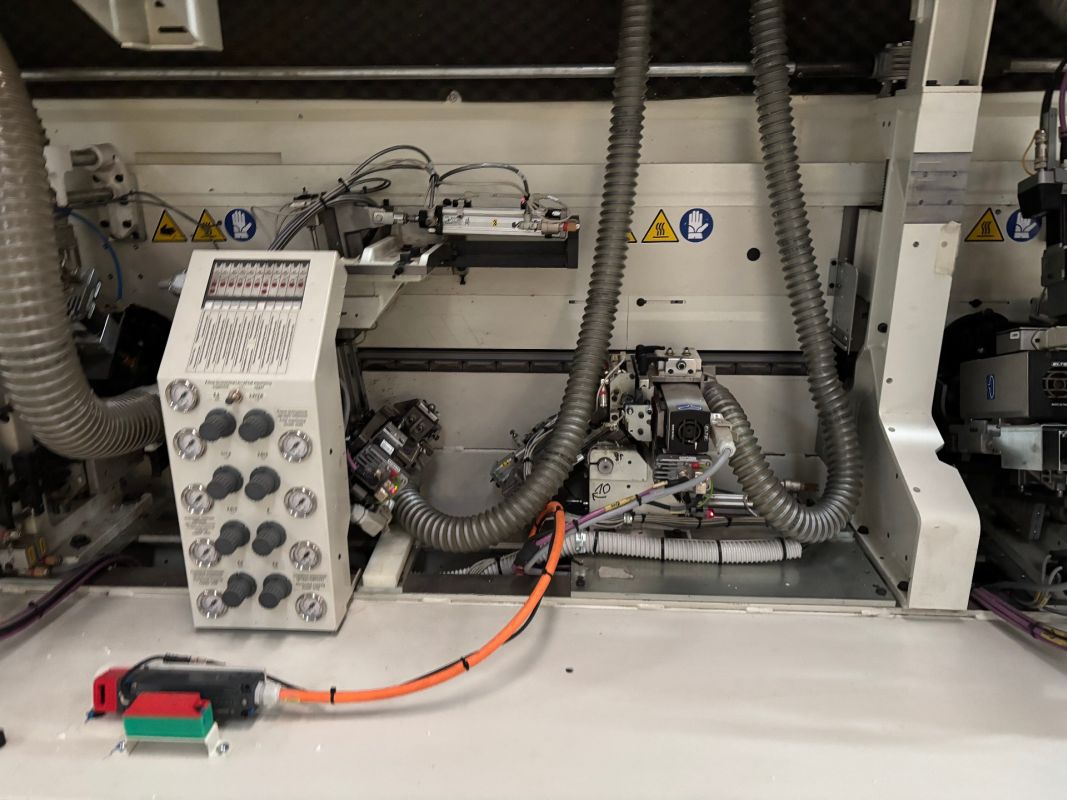

Pre-milling unit “RT-E”

- The unit for pre-milling the panel edge; this results in an optimum glue application surface and a perfect joint line.

- Two time-controlled high-frequency motors to prevent tear-outs.

- Motor power (each): 2.2 kW

- Cutter speed: 9,000 rpm

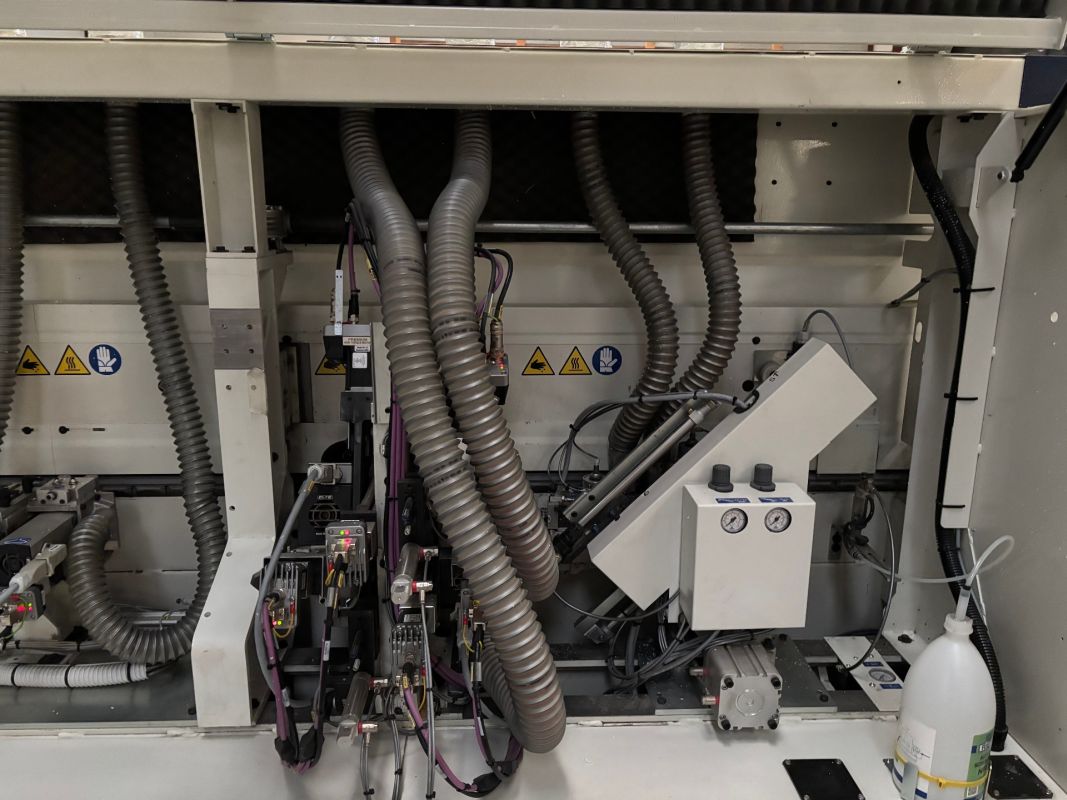

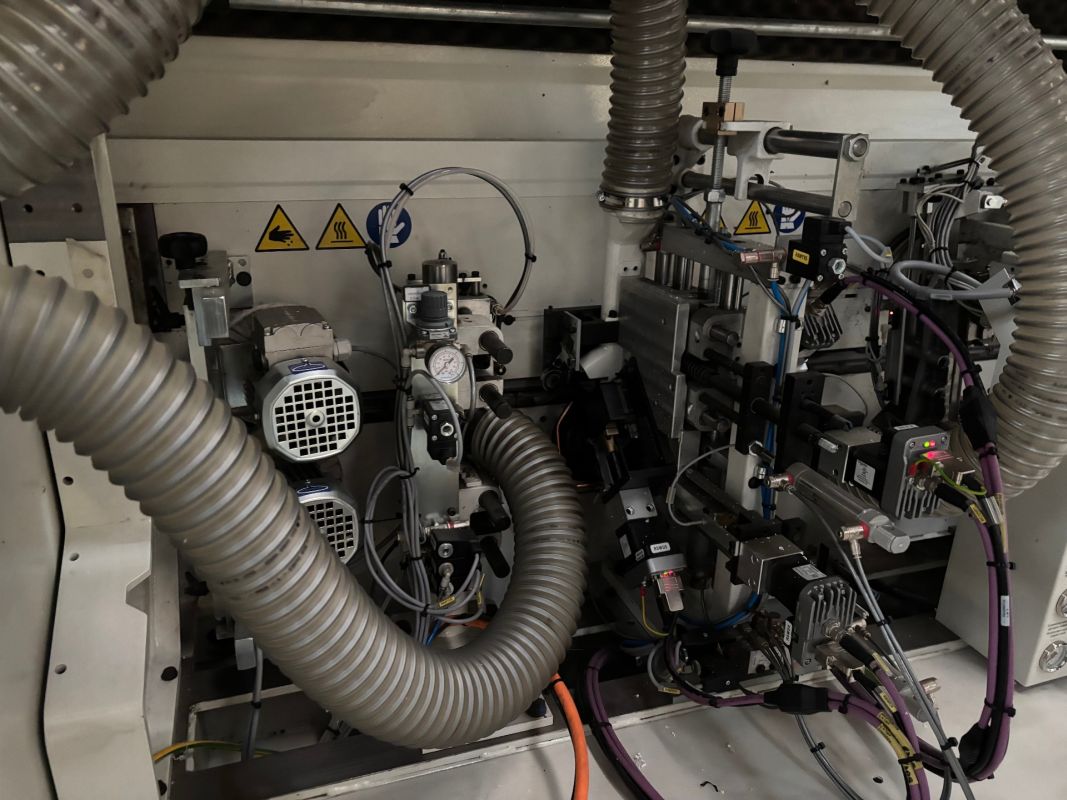

Gluing unit “VC-S4.1/QMS-P”

- For automatic gluing of roll and strip edges with hot melt adhesive on straight panels.

SGP glue container

- Enables a quick change of glue color and glue type.

Pre-melter for EVA glue QMS-P:

- Automatic glue feed with heated glue

2 interchangeable feed rollers:

- One needle roller for solid wood and one knurled roller for thin and plastic edges.

Pressure rollers:

- first driven roller with motor drive and clutch

- 3 rollers without drive, two of them conically offset against each other for perfect edge adhesion, and one cylindrical.

Snipping unit “K/SEL”

- For flush trimming the protruding edge at the front and rear (also for soft/postforming panels)

- 2 high-frequency motors

- Automatic independent inclination (front/rear) of the saw blades 0-15°

- Motor power (each): 0.35 kW

- Saw blade speed: 12,000 rpm

- Automatic saw blade swivel range: 0°-15°

For flush milling top and bottom:

- 2 high-frequency motors

- Manual tilting of the motors

- Motor power (each): 1 kW

- Milling cutter speed: 12,000 rpm

- Motor inclination: 0-25°

Rounding unit “Round SK”:

- Enables rounding of straight or shaped corners and flush routing of the top/bottom panel side.

- Max. Feed speed: 18 m/min for rounding corners and 22 m/min for flush trimming.

- Motor power: 0.55 kW

- Cutter speed: 12,000 rpm

Scraper unit “RAS/1000”

- Eliminates any processing marks left by the previous units from the edges.

- Max. Feed speed: 25 m/min

Buffing unit “SPN”:

- Two independent motors for cleaning and polishing the edges

Maestro active edge” control system:

- Maestro active is the new human-machine interface software common to all SCM technologies.

“eye-M” operating console with integrated PC:

- The color 21.5” LCD display in 16:9 format

Preparation for barcode reader

Non-stick agent spraying unit “AAR”

- Located in front of the joint trimming unit, prevents glue from sticking to the top and bottom of the workpiece and facilitates cleaning. Complete with 2 sprayers and a storage container.

Sprayer for finishing the edge:

- positioned in front of the surface scraper and / or the brushing unit, enables better panel cleaning and polishing of the applied edge.

Top pressure with belt

Feeding aid for narrow workpieces

Preparation for workpiece return “fastback 21-25”

Motors with 4 kW power instead of 2.2 kW

- Motors with an output of 4 kW instead of 2.2 kW for RT/E pre-milling unit

“SGP” glue container with NC dosing instead of the standard container

- Enables automatic adjustment of the dosage depending on the glue/panel type and finishing quality, instead of manual adjustment.

Ceramic lamps with infrared rays

- To heat the edge of the panel before applying the glue.

MultiEdge” device for the RI/S flush milling unit

- For edges with different thicknesses; the installed tool enables the processing of 3 radius edges (e.g.) 1-2-3 mm and numerous thin edges.

Note:

The technical data and descriptions are copied from the original order confirmation. Data is for information purposes only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia

[image=5878/]

[image=5878/]