BrandBIESSE

typeRover A

stateUsed

stock number0401808

year2007

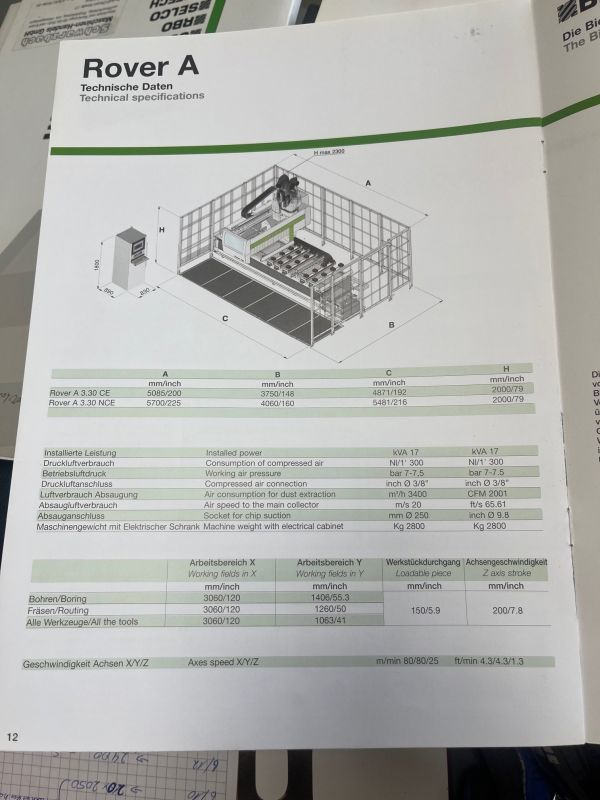

- Working area:

X = 3060 mm,

Y = 1260 mm,

Z = 150 mm

- 7 kW (9.5 HP) electrospindle with ISO 30 adapter

- BH 21L drill head

Questions about this machine

CNC machining centre

Brand: Biesse

Type: Rover A

year of construction: 2007

Technical specifications

- Working range: X = 3060 mm, Y = 1260 mm, Z = 150 mm

- Axis travel: Y = 1635 mm, Z = 200 mm

- The axes are guided on a linear guide with recirculating ball bearings

- Automatic lubrication system

- 6 ATS workpiece supports - L = 1200 mm

- 6 stops with 115 mm stroke, pneumatically lowerable CNC-controlled, Ø 22 mm

- 6 stops with 115 mm stroke positioned at 970 mm from the rear, pneumatically lowerable CNC-controlled, Ø 22 mm

- 4 lateral stops with 115 mm stroke complete with pneumatic equipment, can be lowered pneumatically CNC-controlled, Ø 22 mm

- 4 removable centre stops with 115 mm stroke incl. control, pneumatically lowerable CNC-controlled, Ø 22 mm

- 12 narrow part clamps

- Pneumatic pre-equipment for positioning aid

- 4 positioning aids (each positioning aid can carry 36 kg)

- 18 vacuum modules 132 x 146 x H48 mm (each module can be easily removed and rotated on the module carrier with 15° spacing)

- Preparation for chip conveyor belt integrated in the machine bed

- Vacuum system

- Vacuum pump 90 m3/h at 50 Hz, 108 m3/h at 60 Hz

- Auxiliary vacuum system

7 kW (9.5 HP) Electrospindle with ISO 30 adapter

- 6.6 kW (9 HP), 12000 rpm Insert S1

- 7 kW (9.5 HP) 12000 rpm Insert S6

- Ceramic bearing

- Rotational speeds from 1000 - 24000 rpm NC programmable

Flange for preparing a milling spindle for the use of an angle unit

- includes a flange for mounting on the milling spindle, equipped with 4 conical reference positions at 90° intervals for angle unit

BH 21L drilling head

- equipped with 21 independent tools for single or row drilling on the 5 sides of a workpiece

- Grooves in X-direction on the top of the workpiece

- 14 individually retrievable vertical drilling spindles with a 32 mm pitch, 7 of which in the X direction and 7 in the Y direction

- 3 horizontal drilling spindles with double output and centre distance 32 mm, 2 in the X direction and 1 in the Y direction

- 1 grooving saw in X-direction, diameter 120 mm (cutting depth max. 25 mm)

1 motor with inverter power: 1.7 kW at 2800 rpm, 3 kW at 6000 rpm

- the speed of the drills is variably adjustable up to 6000 rpm

Turret tool magazine with 10 places

- Installed directly on the X - carrier

- for 10 tools or units

- Tool spacing 126 mm

- Max. Ø when fully loaded (10 tools): 120 mm

- Max. tool diameter: 240 mm

- Max. tool length: ISO 30 = 258 mm, HSK = 265 mm

- Max. individual tool weight or weight for angle units incl. tools: 8 kg

- max. total weight: 40 kg

CNC control XP600

Control cabinet

- the machine can be supplied with 380/400/414 V - 50/60 Hz

converter

- for electrospindles with max. power of 14 kW

Note:

The technical data and descriptions are transcribed from the original order confirmation. The information is for reference only and is not legally binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia