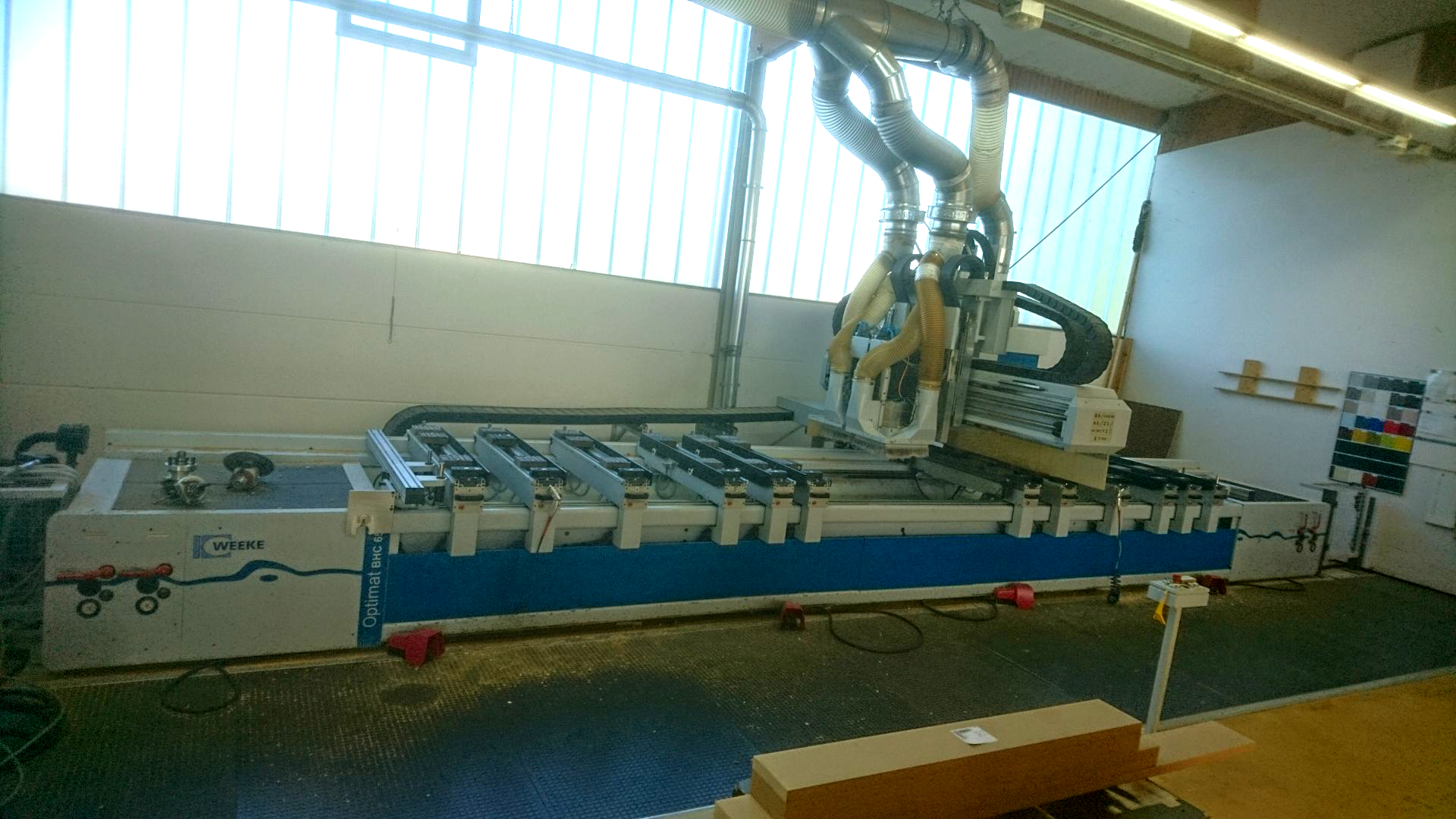

BrandWEEKE

typeOptimat BHC 655

stateUsed

stock number0401519

year2004

4-axis console machine

- 12 workpiece supports

- 6250 mm in X-direction / 2 x 2975 mm in pendulum mode

- 1300 mm in Y-direction

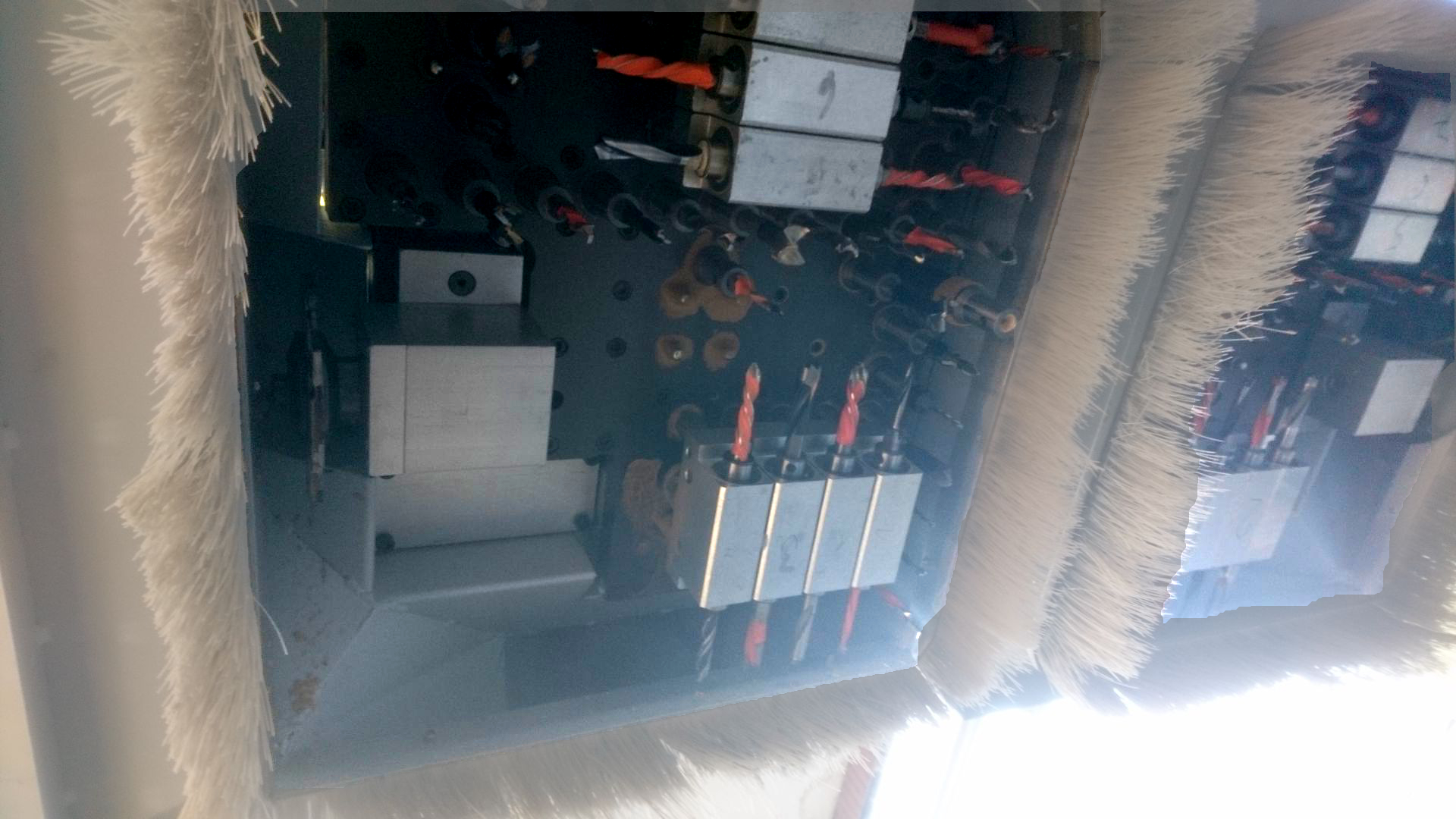

- 2 x drilling head with 23 vertical and 14 horizontal spindles

- 2 milling spindles a 9 kW

- Additional vacuum pump 100 m³/h

- Separate vacuum clamping system (4 vacuum fields in X-direction)

- 18-fold tool holder

- LED positioning system

Questions about this machine

CNC processing centre

Brand: Weeke

Type: Optimat BHC 655

Year: 2004

- axis movement (X-/Y-/Z-direction) via a compact linear guide system, dust-protected

- ball screw spindle (Y- and Z-direction) and rack and pinion drive (X direction)

Software:

WOODWOP, machine data acquisition, provision of teleservice

BASIS-table basic equipment

12 traverses

1 low-maintenance vacuum pump with 100 m³/h output

6 traverses, continuously adjustable in the X direction

4 program-controlled workpiece stops, mounted as a rear row of stops

6 program-controlled workpiece stops, mounted as a front row of stops

2 side stops mounted on an aluminium profile in Y-direction, which can be switched off manually when oversized workpieces are being processed. The side stops can be adjusted manually in Y-direction.

6 workpiece lifting arms for heavy workpieces

Milling spindle HSK 9 kW (S6 50%), liquid circulation cooling

Speed: stepless adjustable 1250-24000 UpM

360° positioning axis

Additional side stop cylinder, pneumatically lowerable

Additional longitudinal stop cylinder, pneumatically lowerable

Double centre stop lockable with 4 cylinders

The stop cylinders can be adjusted manually to a limited extent in Y-direction.

Position 1: 300 mm (X-direction)

Position 2: 1000 mm (X-direction)

Note: The positions given refer to the dimension between the two centre stops. Aligned to the pendulum situation.

Additional vacuum pump 100 m³/h

Separate vacuum clamping system (4 vacuum fields in X-direction)

Separate vacuum clamping system for the use of at least 8 workpiece supports with four-fold assignment

18-fold tool holder

LED positioning system

Note:

The specifications and descriptions are a copy of the order confirmation at that time. Data are for information and are not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia