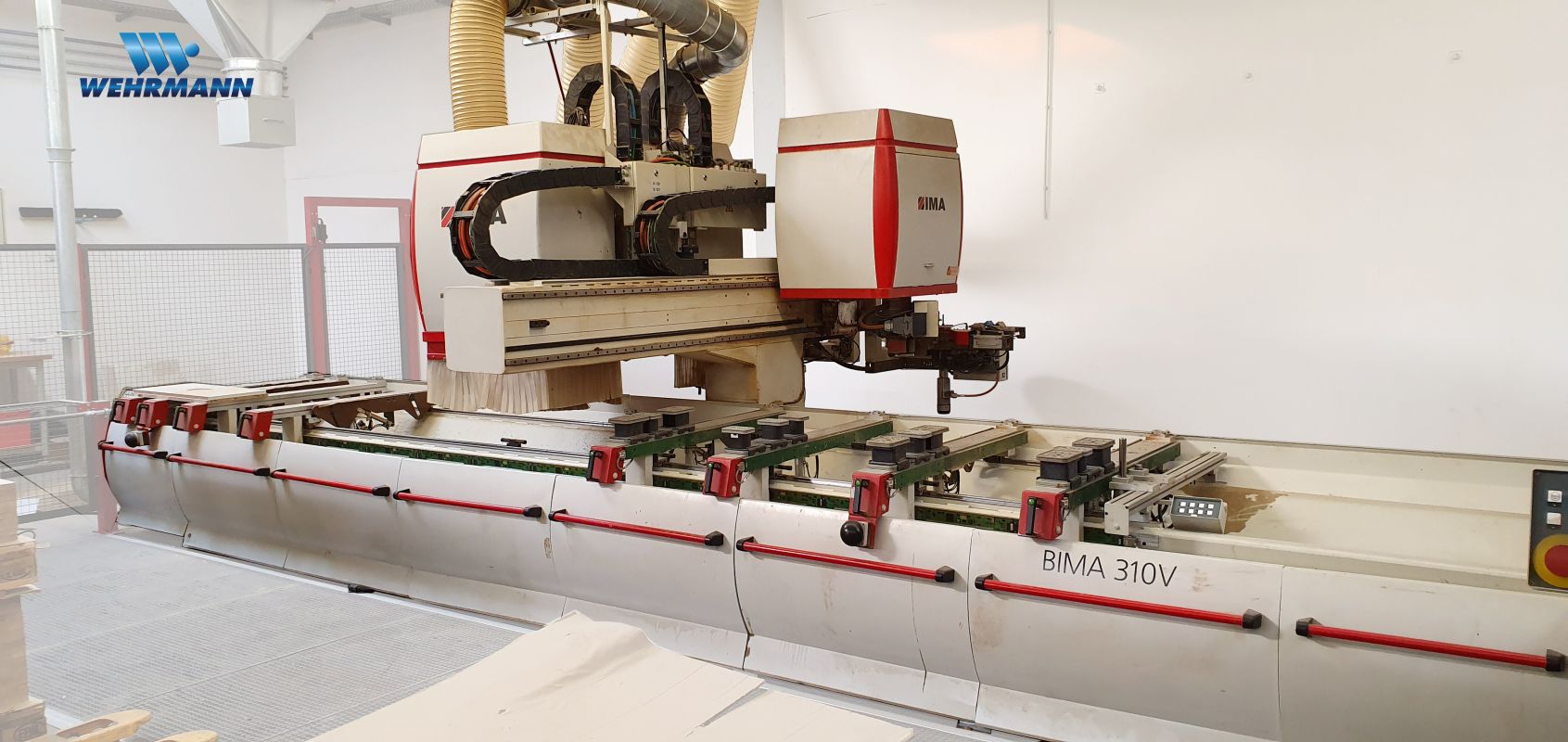

BrandIMA

typeBIMA 310V 120/600

stateUsed

stock number0401531

year2004

- in X-direction without gluing 6000 mm

- in X-direction motor gluing 5000 mm

- in Y-direction 1200 mm

- in Y-direction with main spindle + WZ-Ø 20 mm 1300 mm

- Tool holder: HSK F63

Questions about this machine

CNC processing centre

Brand: IMA

Type: BIMA 310V 120/600

Year: 2004

Technical data:

Machining area

- in X-direction without gluing 6000 mm

- in X-direction motor gluing 5000 mm

- in Y-direction 1200 mm

- in Y-direction with main spindle + WZ-Ø 20 mm 1300 mm

max. clamping height from

Upper edge of suction plate Z1 100 mm

max. workpiece thickness Z 2 depending on equipment/application

Worktable height: approx. 950 mm

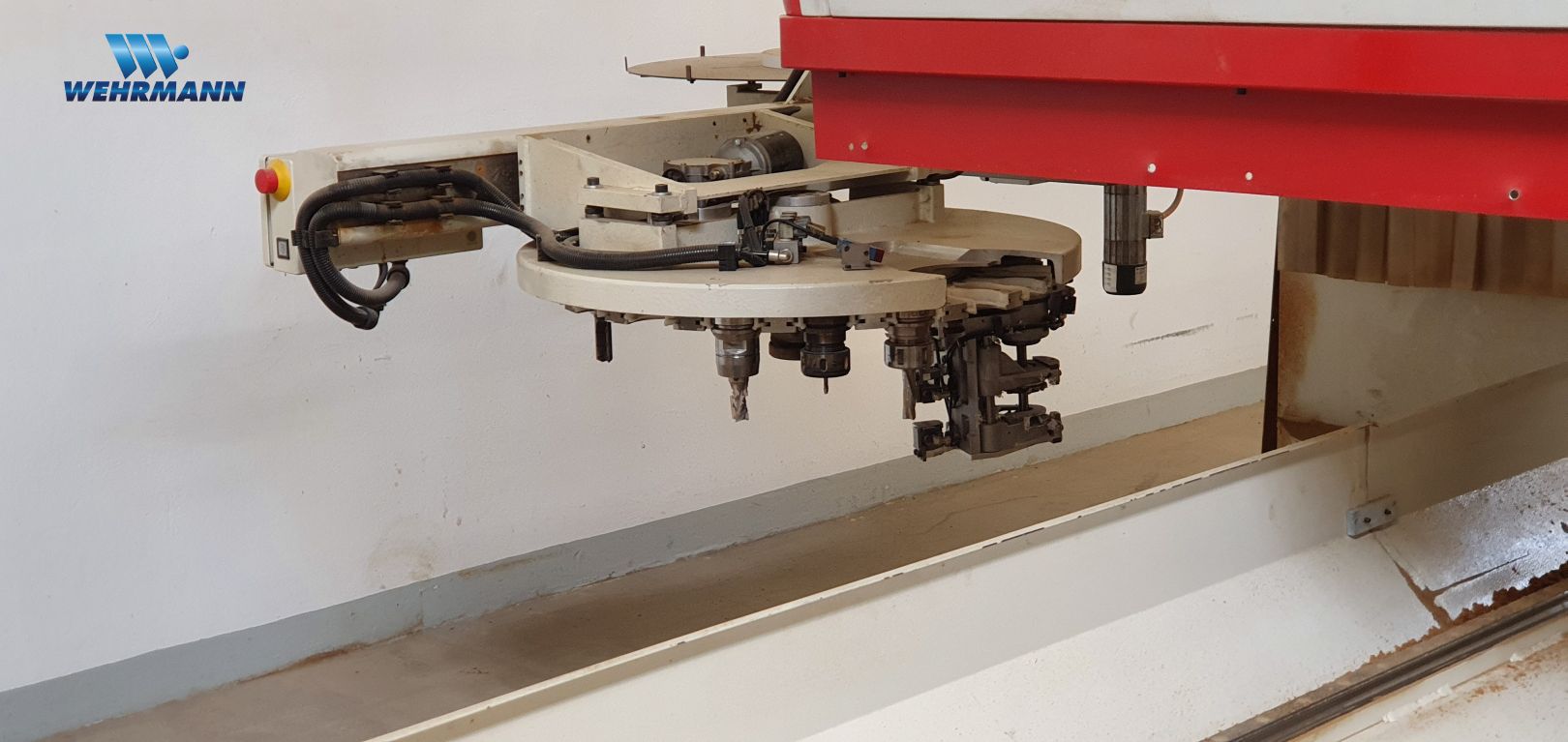

1 main spindle with feed stroke pneum.

- Drive power: 12 kW in S-1 operation

- Tool holder: HSK F63, taper diameter =38 mm

- Tool feed: automatic

- Pull-in force: 11000 N

- Tool weight: max. 6 kg

- Direction of rotation: right/left rotation, programmable

- Speed range: stepless 1500 - 24000 rpm, programmable

- Drive: frequency-controlled three-phase motor

Spindle lubrication: unique factory grease lubrication

- spindle cooling: water cooling

1 CNC axis rotating 360 degrees

1 vertical drilling unit S21

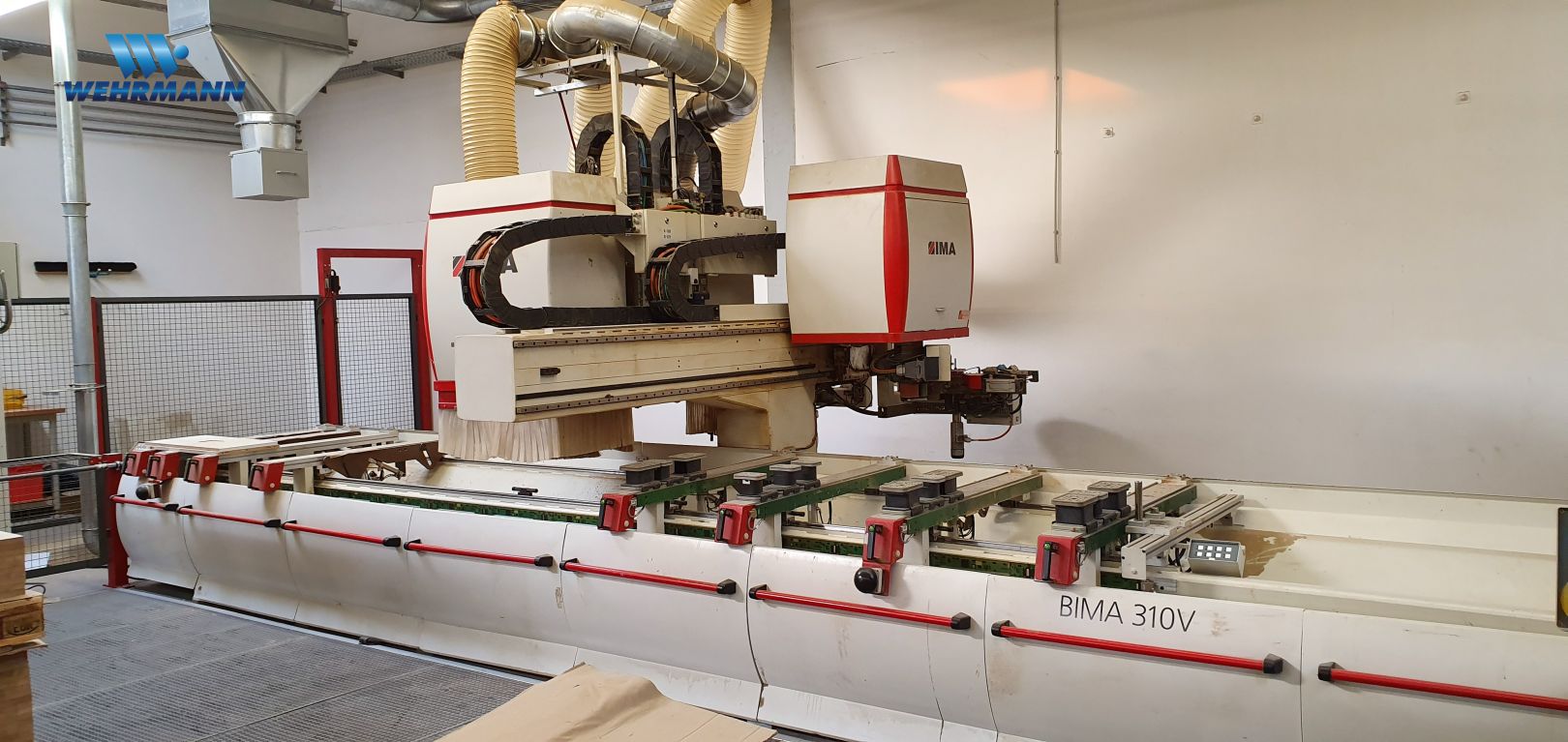

Machine table consists of:

6 support arms, infinitely adjustable in X-direction, with one rear and one middle stop each, all stops program-controlled

6 sets of suction plates consisting of a total of

6 suction plates 114 x 159 x 100 mm

6 suction plates 125 x 75 x 100 mm

The support arms and suction plates can be individually positioned to the corresponding workpiece size.

Alternating field area:

without pendulum machining, without gluing: X = 2 x 2900 mm

Free space in the middle: X = 200 mm

without pendulum machining, with gluing: X = 2 x 2150 mm

Free space in the middle: X = 700 mm

with pendulum machining, without gluing: X = 2 x 2400 mm

Free space in the middle: X = 1200 mm

with pendulum machining, with gluing: X = 2 x 1700 mm

Free space in the middle: X = 1600 mm

Feed drive system Rapid traverse:

- X axis 100 m/min.

- Z axis 25 m/min.

Air pressure: 6 bar

Tool change magazine 18-fold

Tool coding: place-coded

Tool weight: max. 6 kg

Tool length: max. 150 mm

Tool Ø: max. 100 mm at full occupancy

max. 150 mm with free secondary places or nestings

Central connection for extraction

Mains voltage: 3/N/PE, 400/230 V, 50 Hz

1 vacuum pump 100 m3/h

Note:

The technical data and descriptions are copies of the order confirmation at that time. Data are for information and are not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia