BrandWEHRMANN

typeCombima /K/I/R80/1260/V

stateNew

stock number0401589

• Directpostforming machine for curved caravan furniture fronts

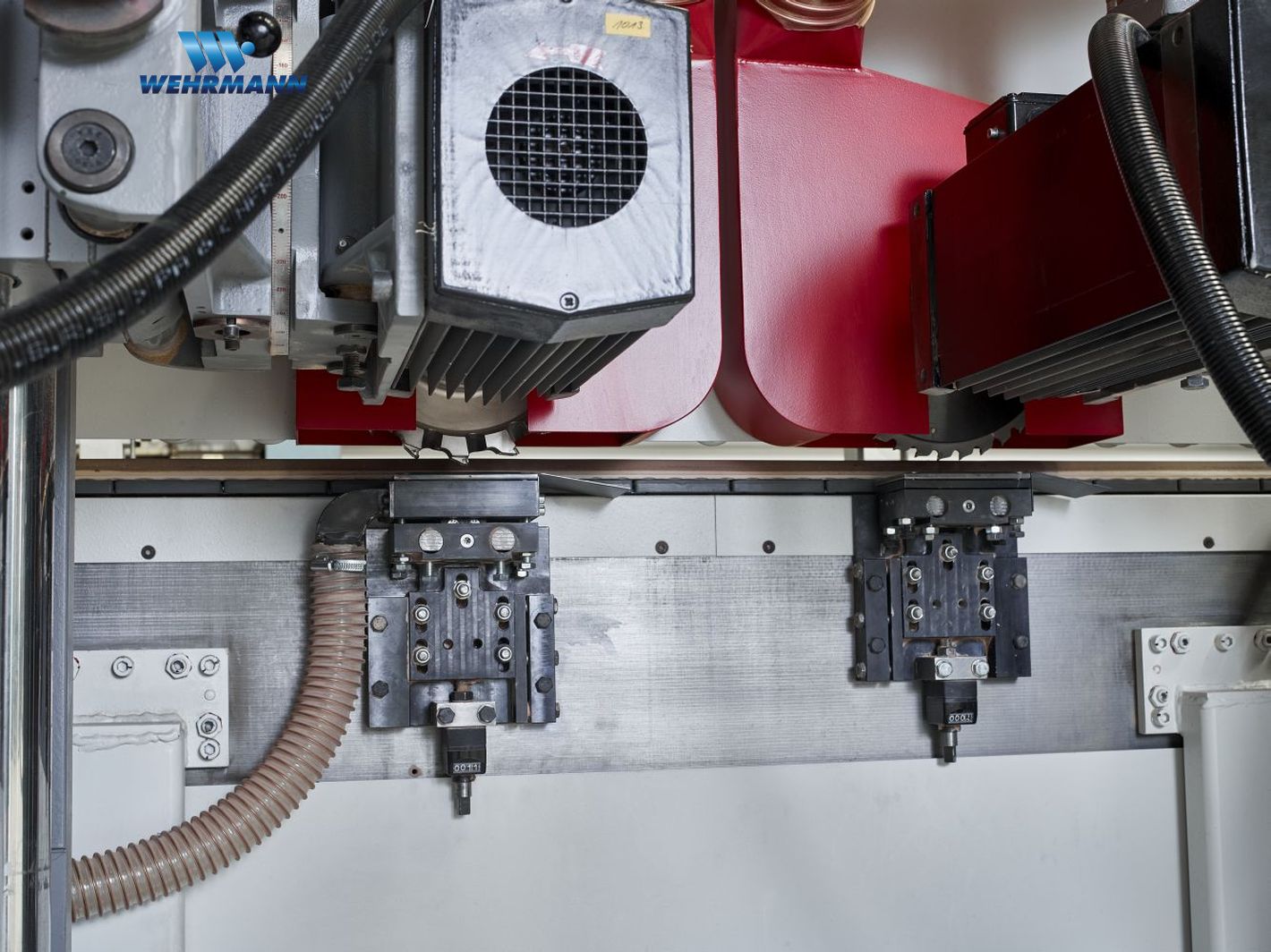

• With scoring and folding technology in the edge area

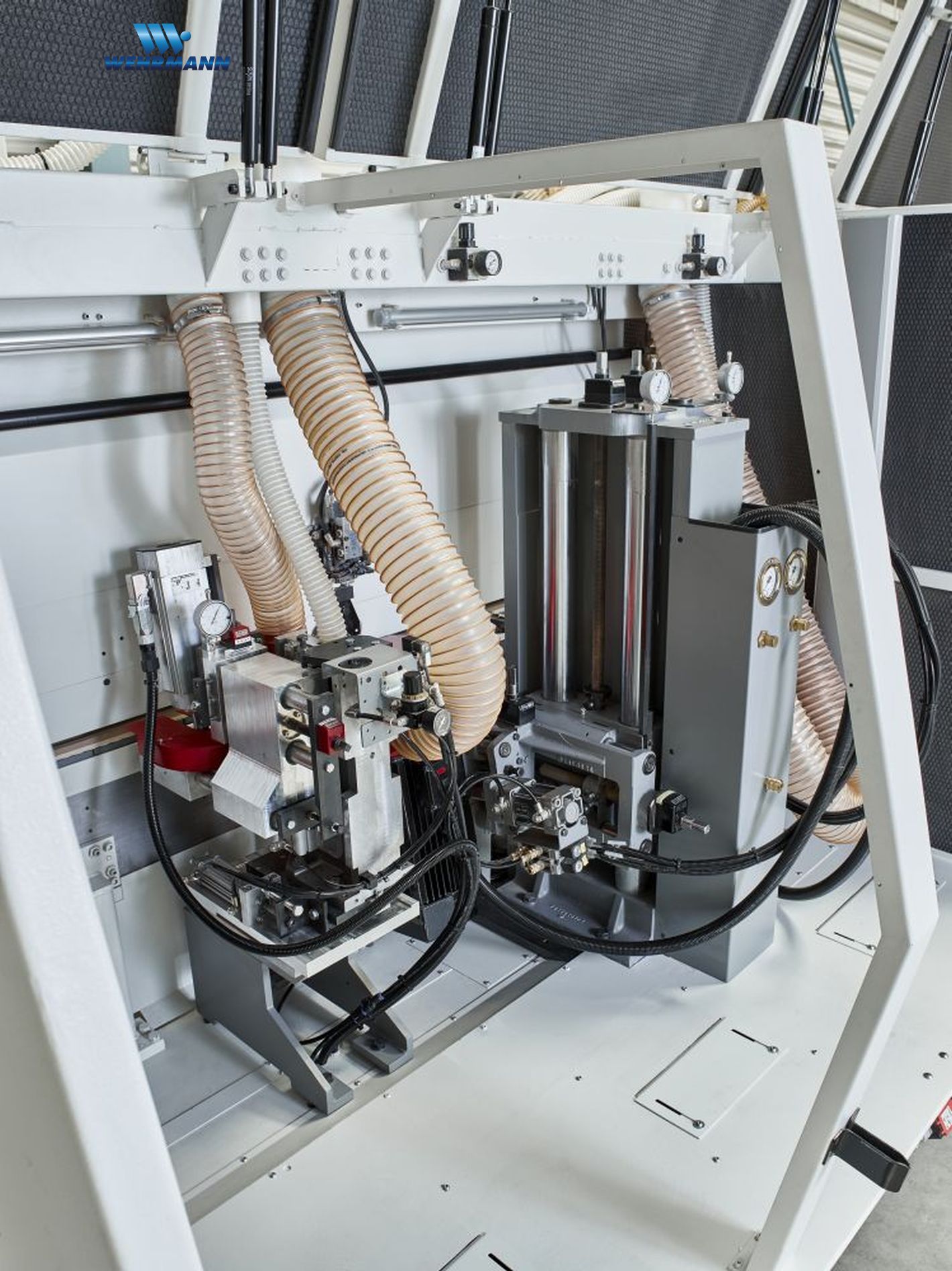

• Easy to adjust counter pressure device for nearly every radius

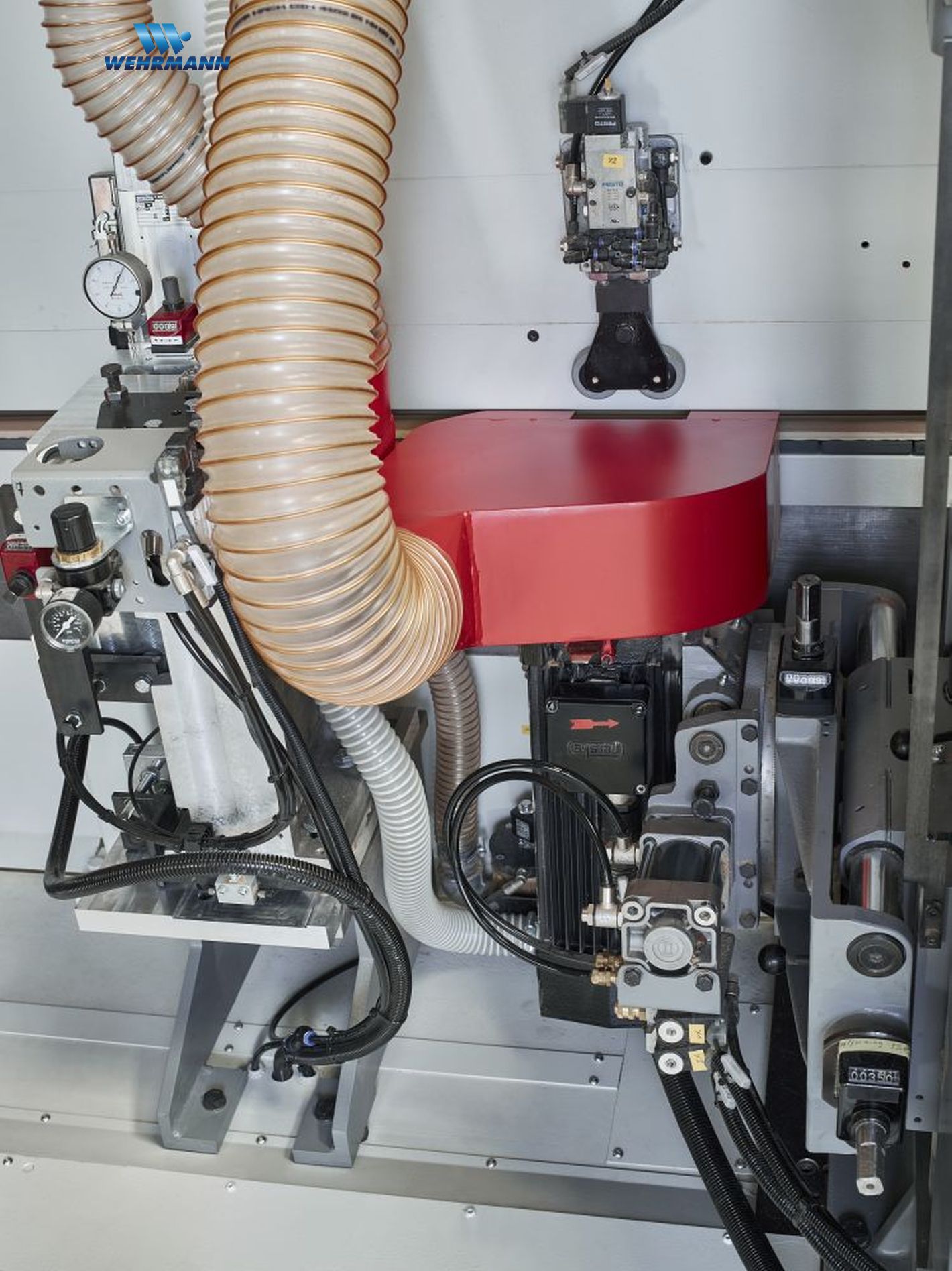

• 2 Nordson PU – barrel melting devices

• Decorative grooves near to the edge, inside the area of the chain

Questions about this machine

single-sided direct postforming machine

Brand: Wehrmann

Type: Combima /K/I/R80/1260/V

Example offer direct postforming machine

Varied using for doors, worktops, furniture parts, curved caravan fronts, etc.

Technical data:

A single-sided throughfeed postforming machine for the

postforming and postfolding process, for processing curved

workpieces in caravan construction. For workpieces to be

profiled made of wood/wood materials with laminate

(CPL,HPL) as surface material. The laminate protruding

for the postforming process is located in the machine

on the underside of the workpiece and is formed

from the bottom to the top.

Technical data "Machine"

Constant workpiece projection

from the chain conveyor: from approx. 35 mm

Throughput width min.: 130 mm ( only for straight parts )

Workpiece length in

feed direction min.: 1,000 mm

Basic height: 940 mm (upper edge of chain conveyor)

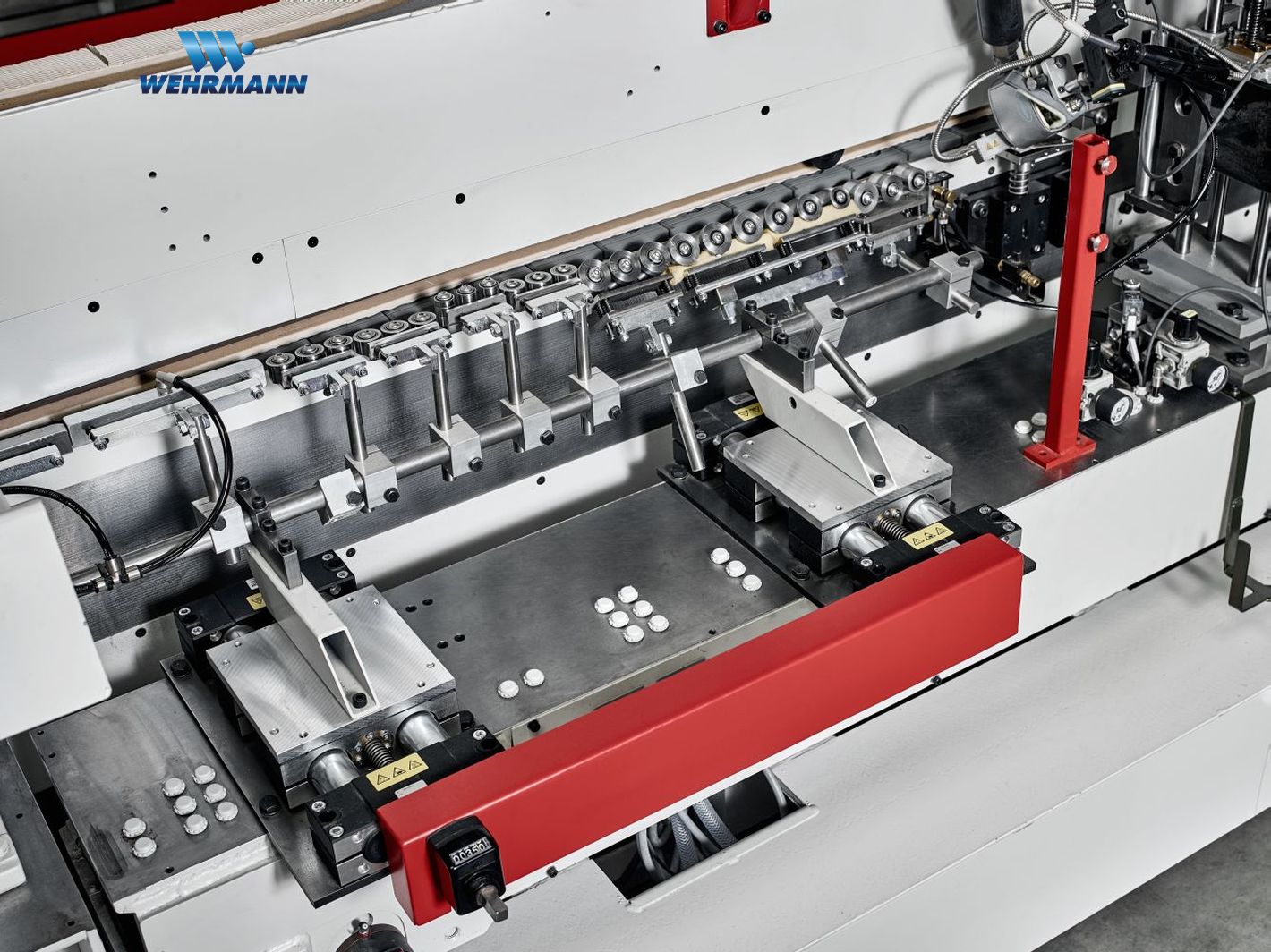

The workpiece is transported

by means of the R75 precision roller chain with height-adjustable top pressure.

upper pressure. The low-maintenance precision roller chain

has 75 mm wide and 85 mm long rubber-coated chains.

Due to the 80 mm wide compound V-belt of the top pressure

the workpieces are reliably guided.

Special version of the top pressure

for fitting to different workpiece radius.

Left-hand machine:

fence side left in machining direction

1 fence ruler

on the fixed machine side

Feed speed:

max. V=6-30 m/min.

Mains voltage:

3/N/PE, 400/230 V, 50 Hz,

Control voltage:

24 V DC / 230 V AC

Top pressure:

motorised height adjustment

Release agent via spray nozzle from above

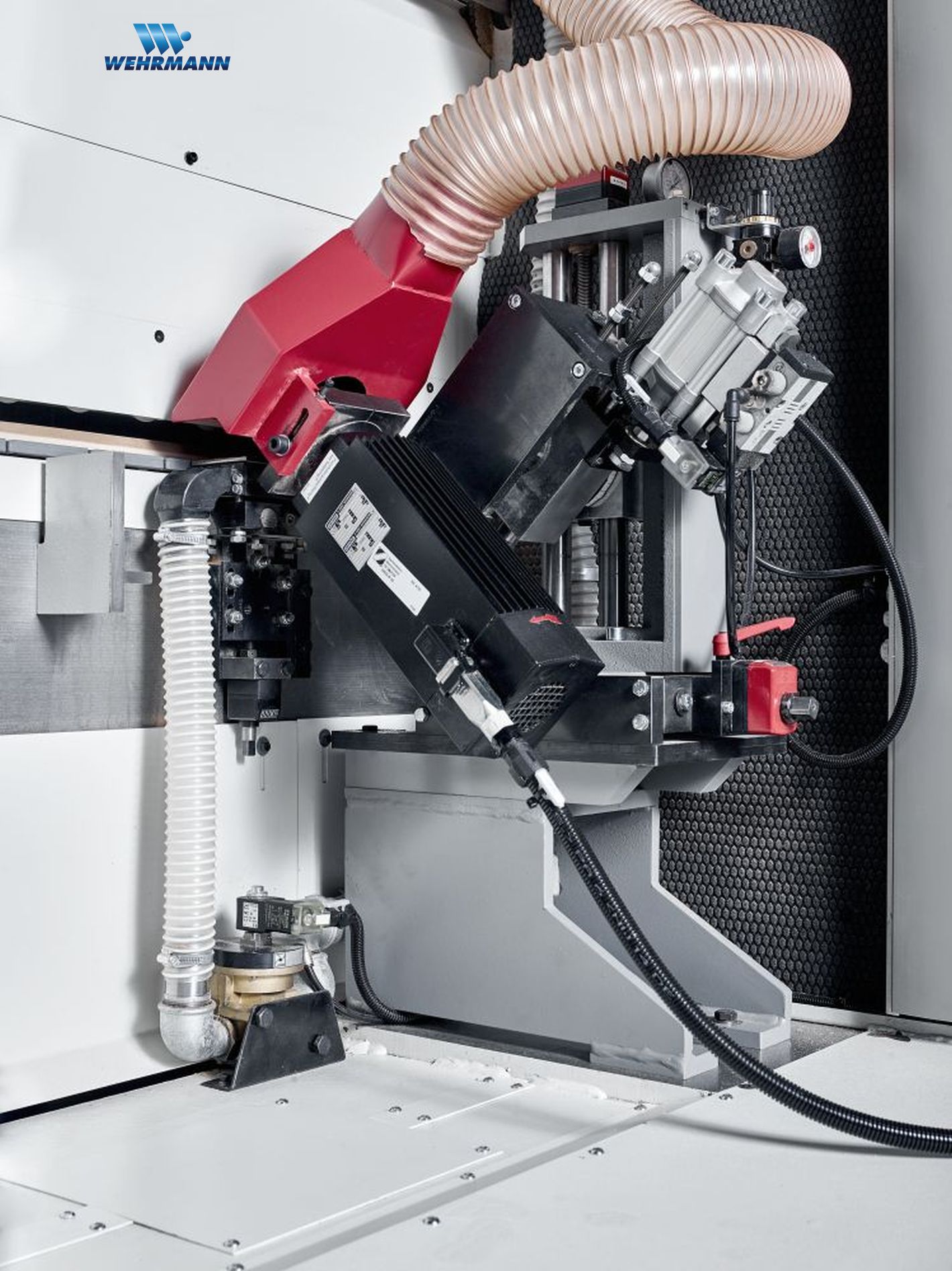

Front of stand:

Pre-milling unit swivelled approx. 3 degrees

with 1 horizontal motor, 400 V, 12.5 KW

Stand rear side:

Pre-finishing/milling unit

with 1 motor horizontal, 400 V, 12,5 KW

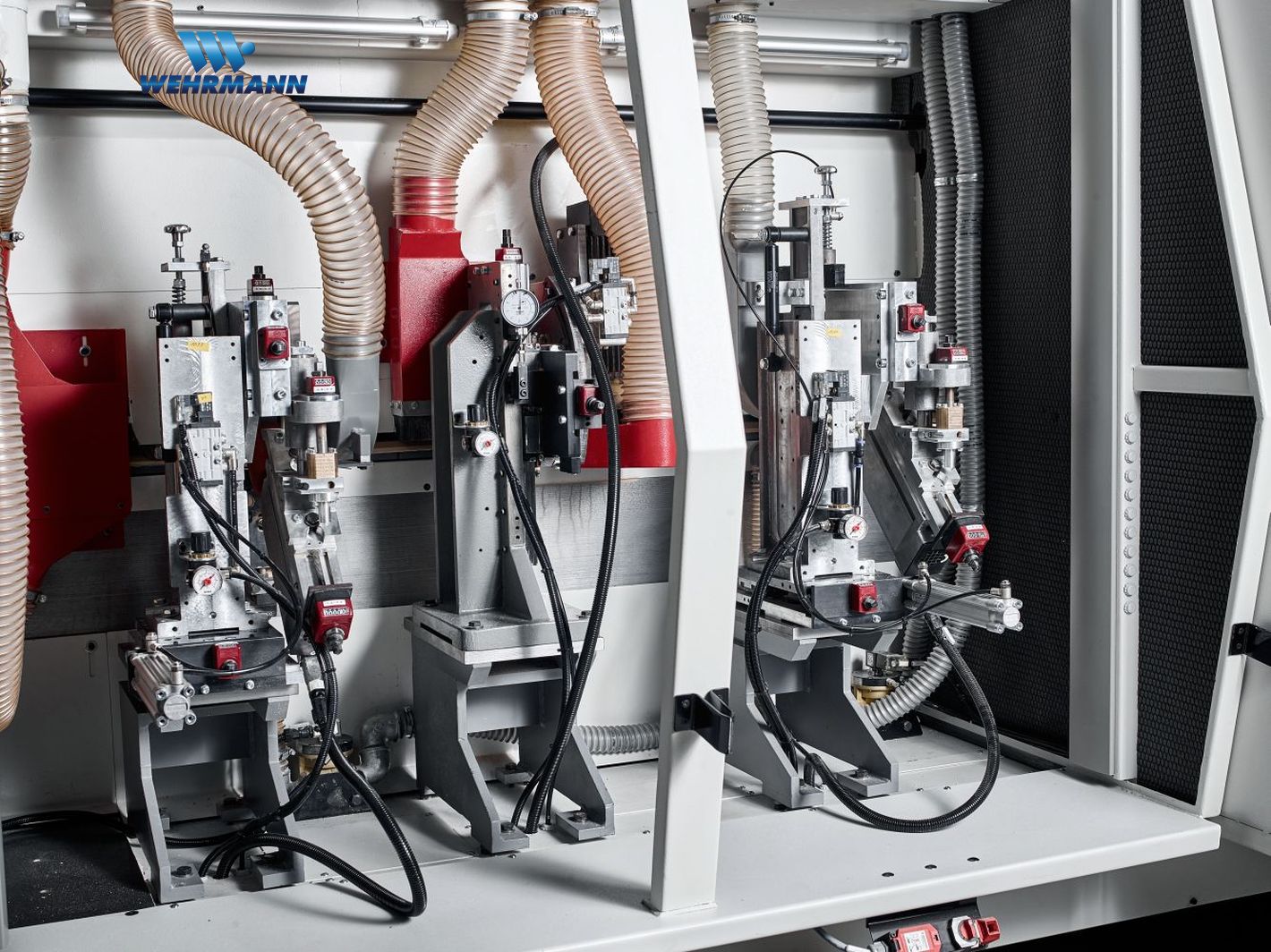

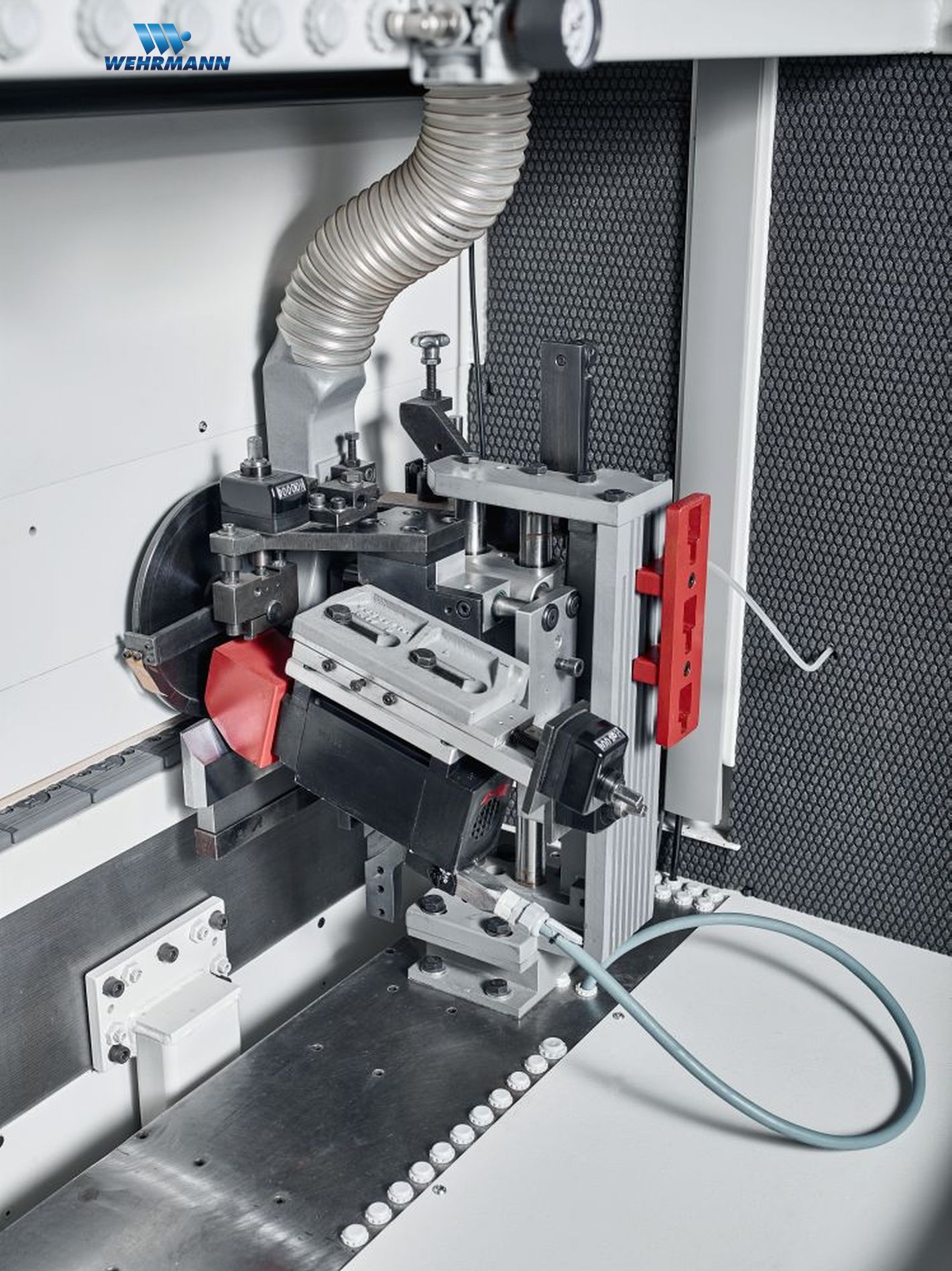

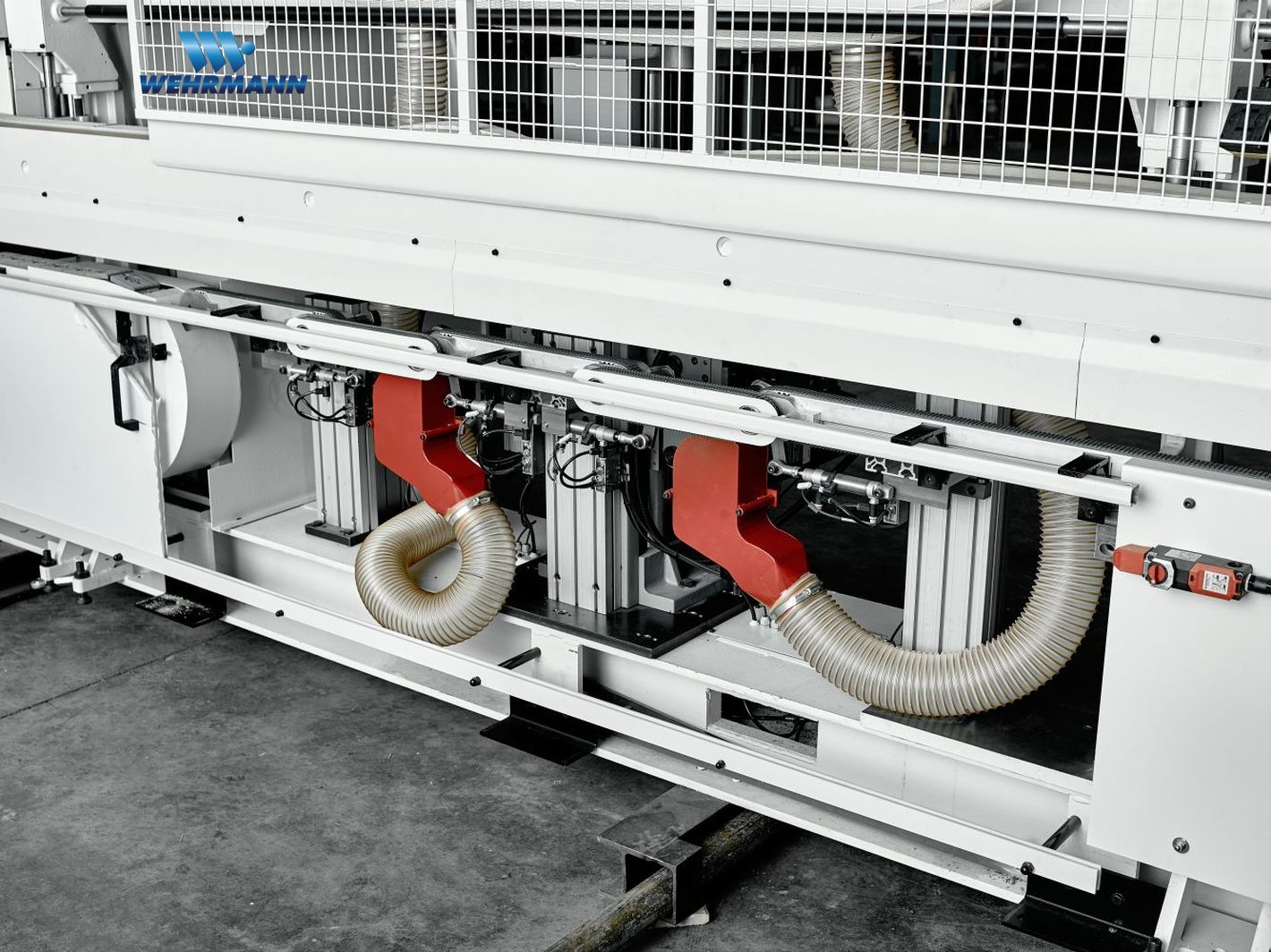

Front side of upright:

Relief cutting for internal profiles

with 1 motor horizontal 400 V, 6,6 KW

Rear side of upright:

Milling unit for internal profiles

with 1 horizontal motor 400 V, 6.6 KW

Front side of upright:

Flattener swivelled approx. 120 degrees

with 1 horizontal motor 400 V, 6.6 KW

Rear side of upright:

Radius milling approx. 100 degrees swivelled

with 1 motor horizontal 400 V, 6,6 KW

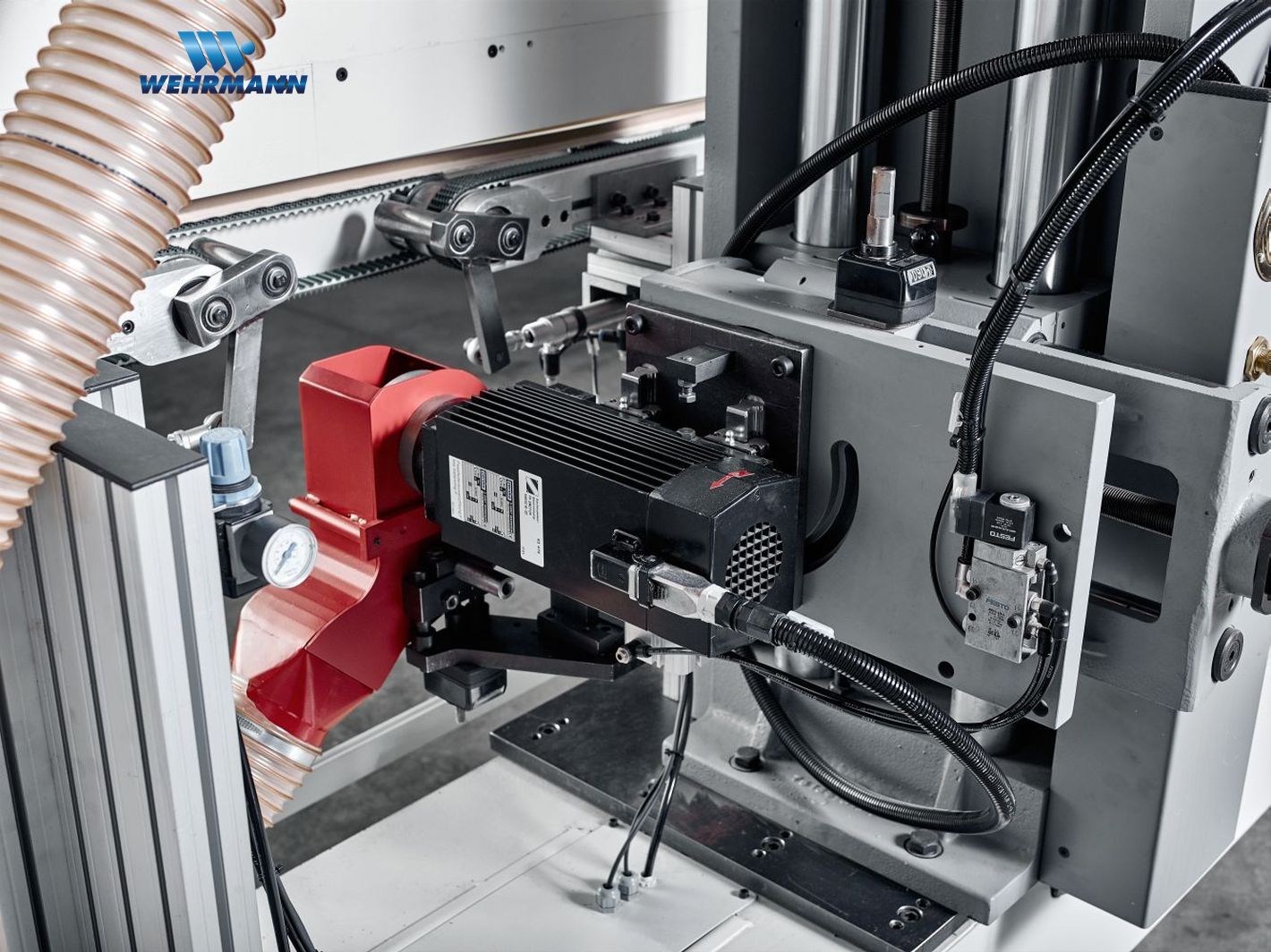

Pointing unit

with 1 motor hanging 400 V, 1 KW, HSK 25

Free space

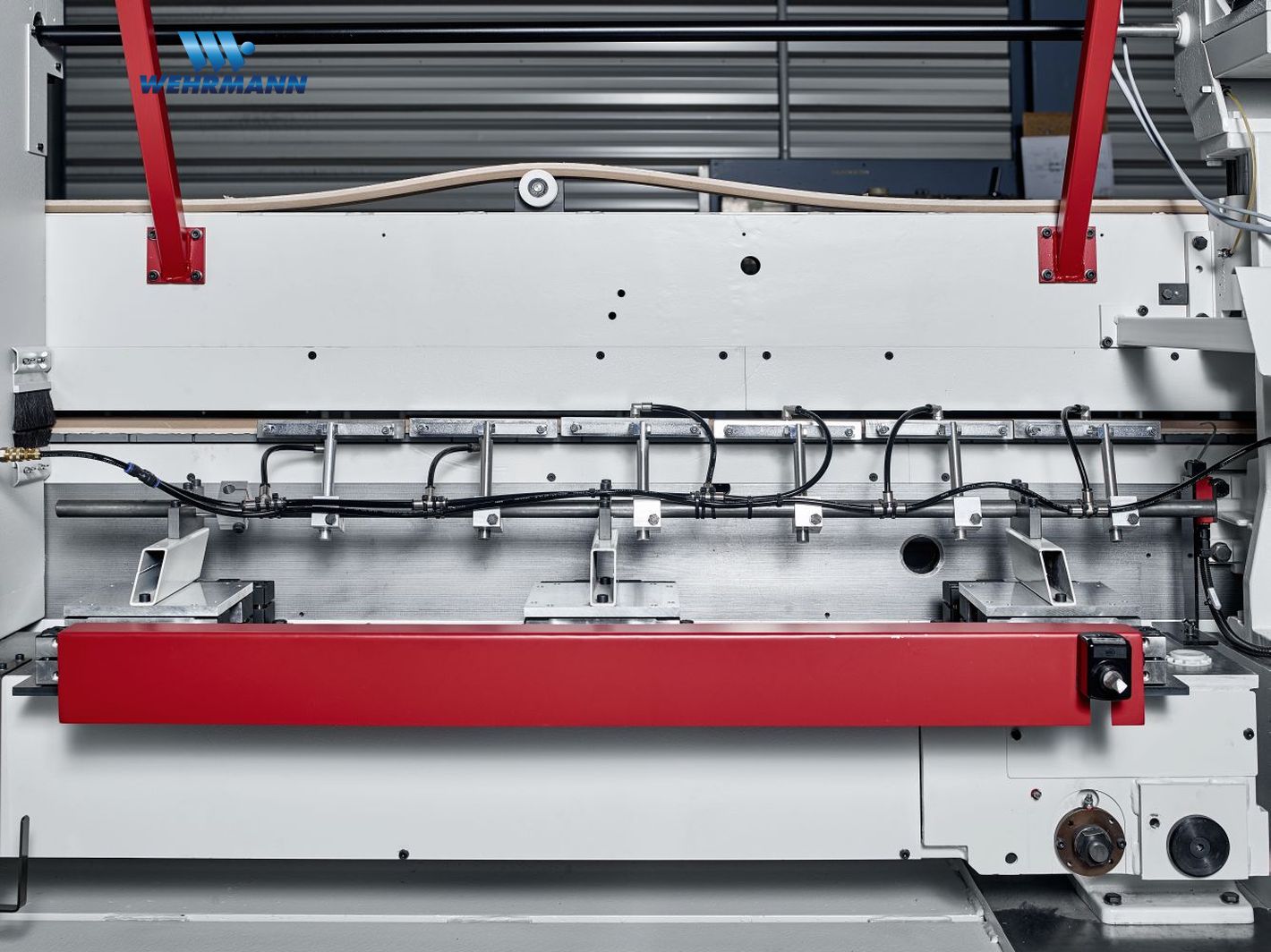

Heating zone

PU glue application of the "gusset bead" in the

Spotting area

By means of NORDSON - drum melter

PU-glue application onto the surface

Lubricant spraying device from below

Profile pressure section with firmly mounted glide shoes

for 2 profiles

Cooling zone via glide shoe technology

Air on/off control

Cleaning via spray nozzle from below

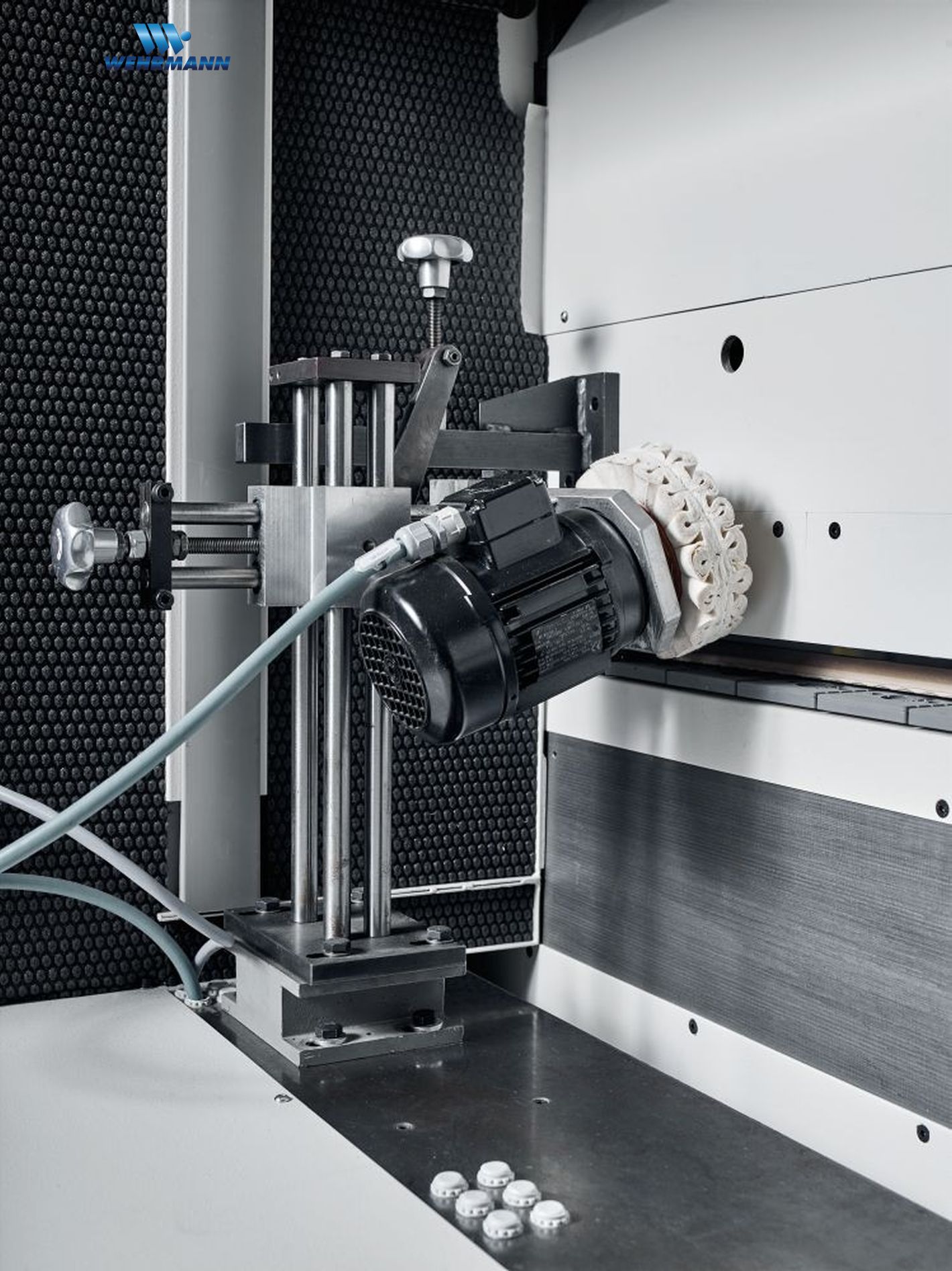

Fibre unit 08.055 from above

with one motor 660 W, 400 V, 200 Hz

Buffing unit from above

2 grooving units

Part support with a double roller rail

-rubberised-

Postfolding

Aggregate for bevelling 08.0587

With 1 motor for fine milling from above

Aggregate for bevelling 08.0587

With 1 motor for fine milling from above

With 1 motor for fine milling from above

Aggregate for bevelling 08.0587

With 1 motor for fine milling from above

With 1 motor for fine milling from above

2 Nordson bead application heads

1 Nordson PUR flushing system

Note:

The specifications and descriptions are a copy of the order confirmation at that time. Data are for information and are not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia