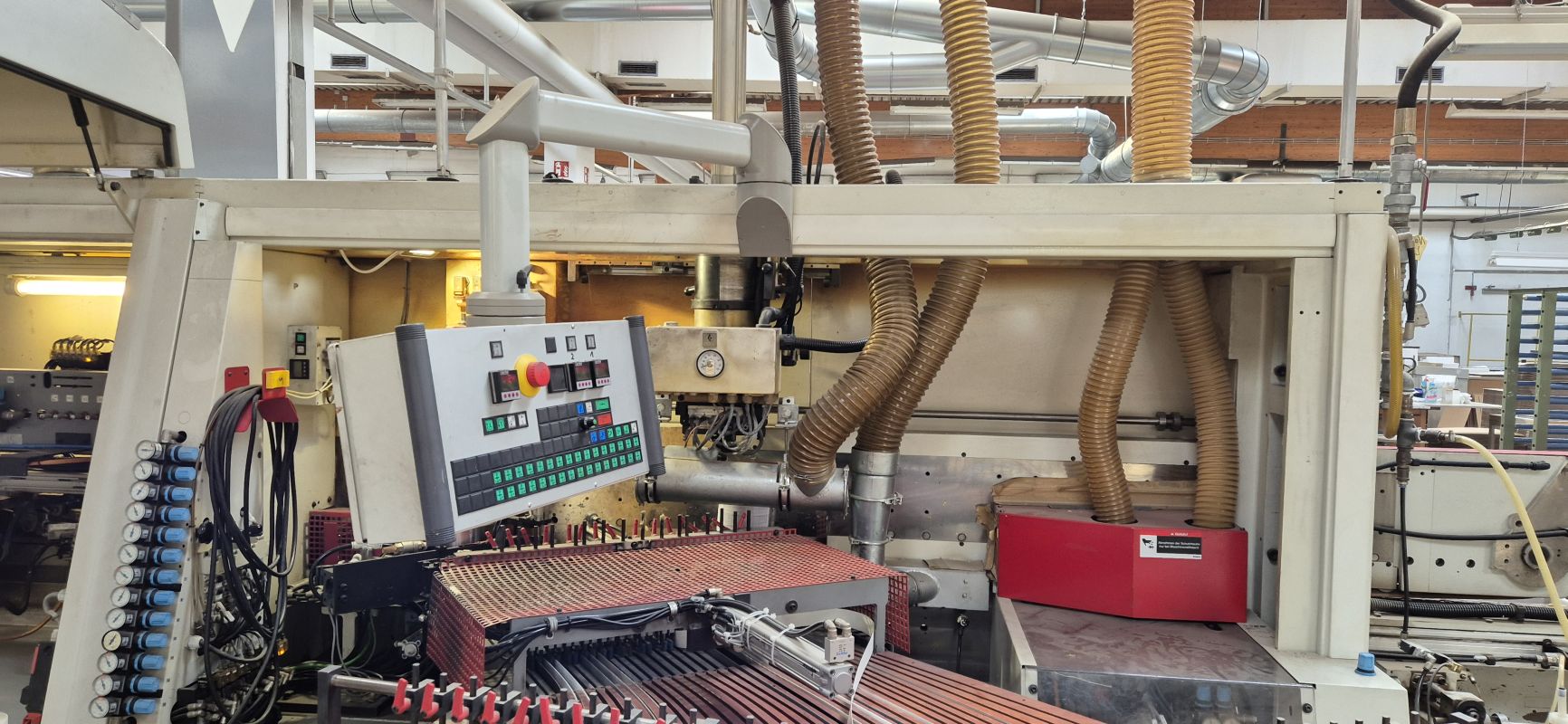

BrandIMA

typeNovimat Systems/I/R75/1000

stateUsed

stock number0401824

year2005

- Jointing milling unit with 2 motors, each 4.5 kW

- Infrared heater, approx. 300 mm long, 2 x 1.5 kW

- Gluing unit

- Vertical roll holder for 32 rolls

- End trimming unit on top pressure beam with 2 motors, each 200 W

- Milling unit with 2 motors, each 1000 W

- Multi-functional processing unit 2 motors 660 W

- Spray nozzles top and bottom

- Multi-profile scraper unit

- Flat scraper unit

- Copy buffing unit 4 motors 250 W

- Smoothing unit

Questions about this machine

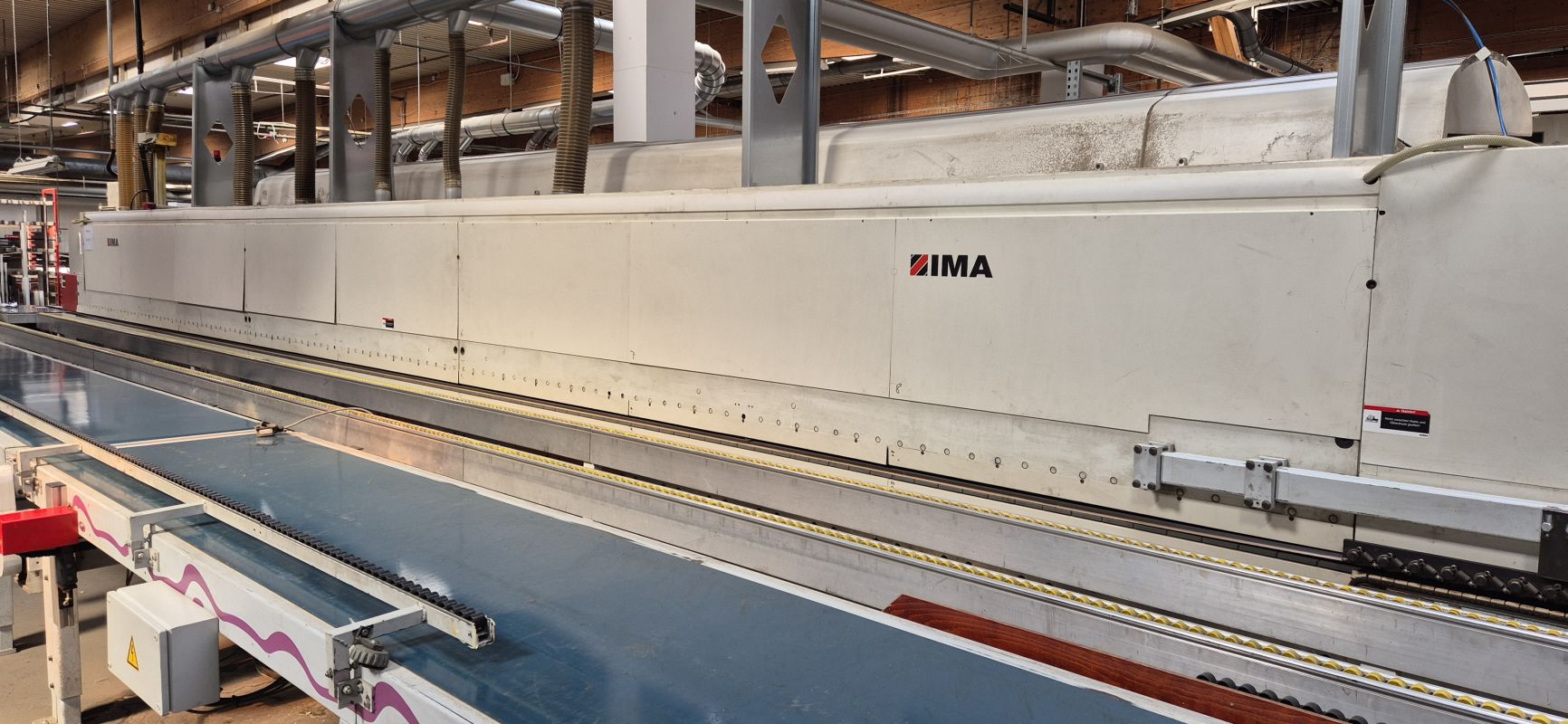

single-sided edge banding machine

Brand: IMA

Type: Novimat Systems/I/R75/1000

Year of manufacture: 2005

technical data

PC Control

- ICOS OPEN control system

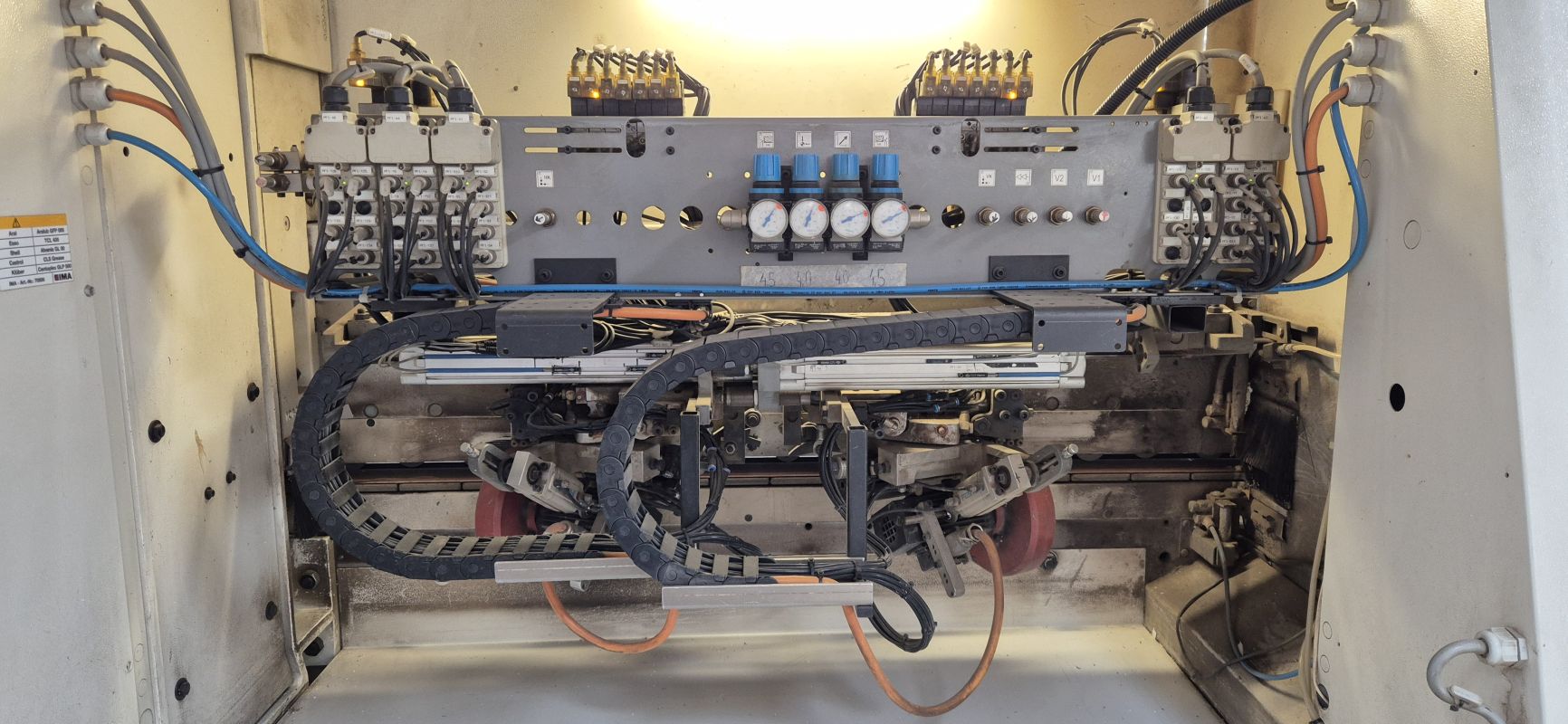

Feed speed: 5-25 m/min, frequency-controlled

Stop ruler with electronic positioning control

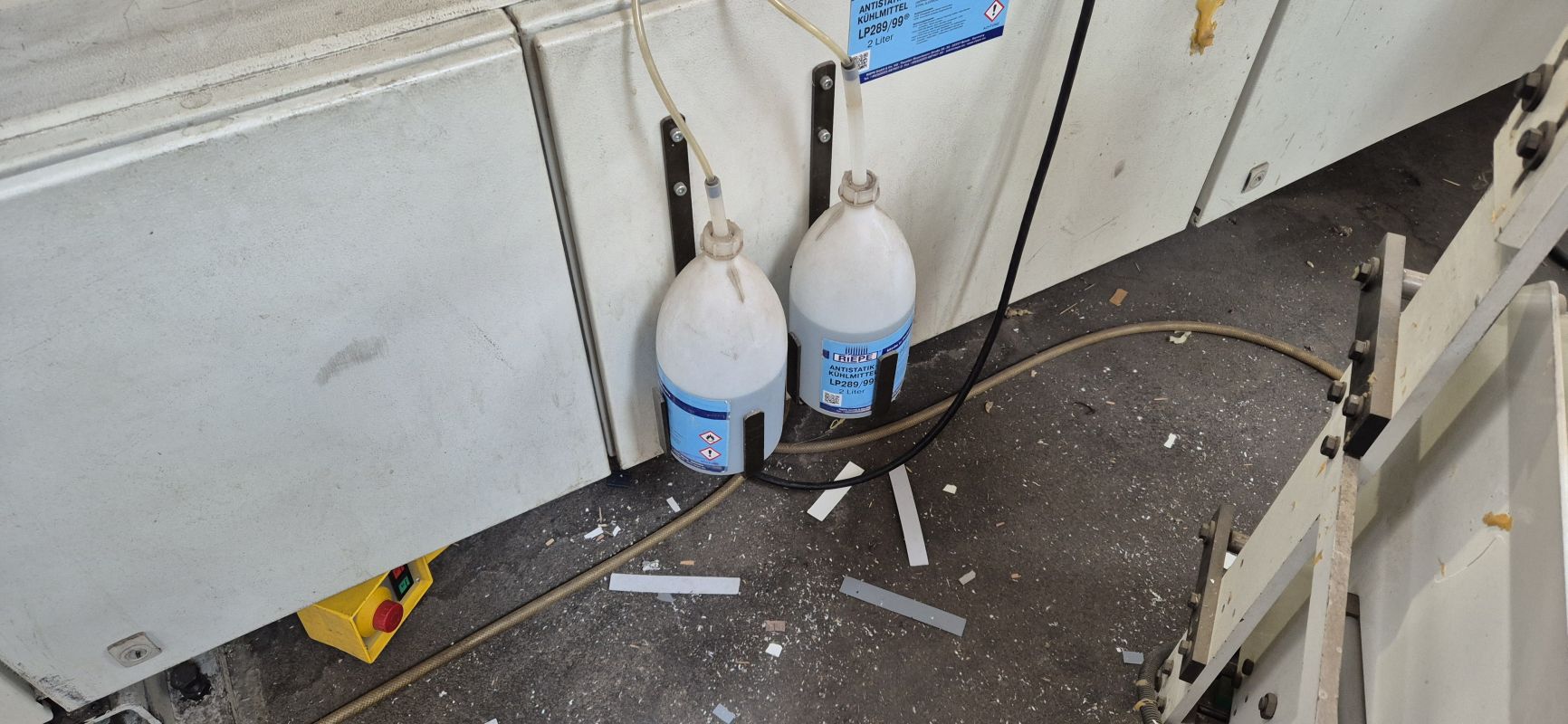

Release agent application top and bottom

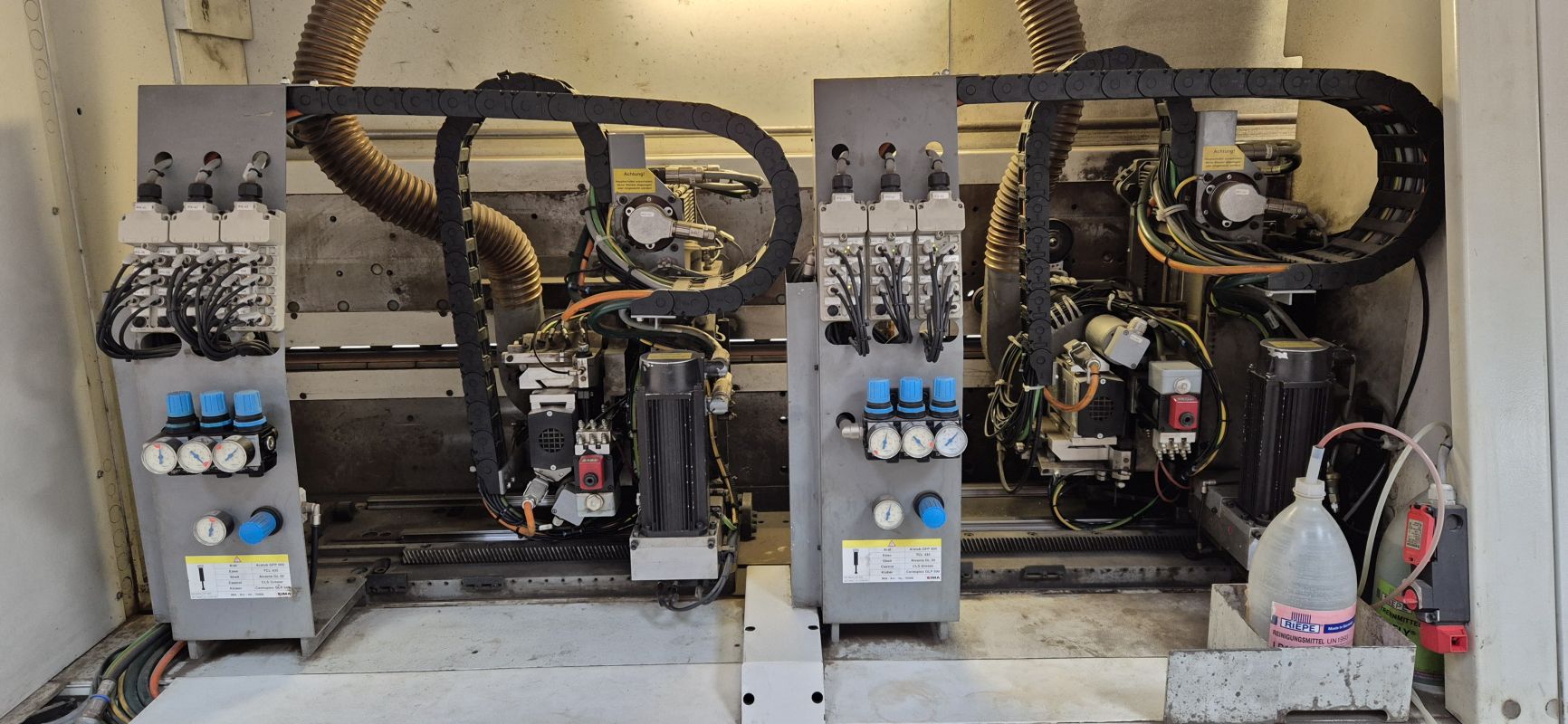

Jointing milling unit with 2 motors, each 4.5 kW, 9,000 rpm, controllable

- Horizontally adjustable via axis

Infrared heater, approx. 300 mm long, 2 x 1.5 kW

Gluing unit

- Glue application with pneumatic quick-lock system

- Automatic PU melting system “Quickmelt” for 2 kg cartridge containers

- 32-position edge magazine (8 tracks up to 3 mm / 24 tracks up to 1.3 mm)

Vertical roll holder for 32 rolls, max. diameter 850 mm

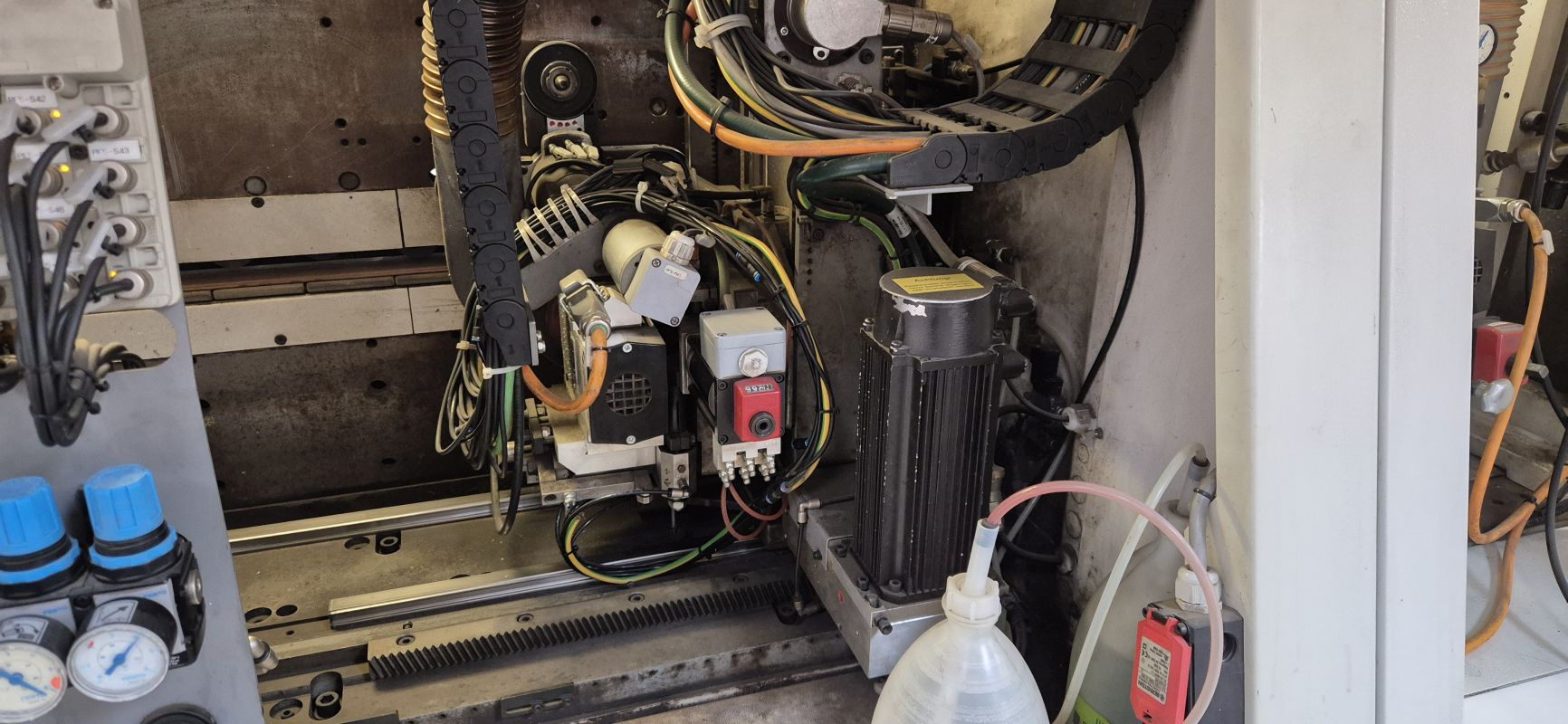

End trimming unit on top pressure beam with 2 motors, each 200 W, 400 V, 12,000 rpm

- Horizontal pneumatic swivel 0-25°

- With controllable side tracing, for 3 edge thicknesses

Milling unit with 2 motors, each 1000 W, 400 V, 200 Hz, 12,000 rpm

- Operating in counter-rotation

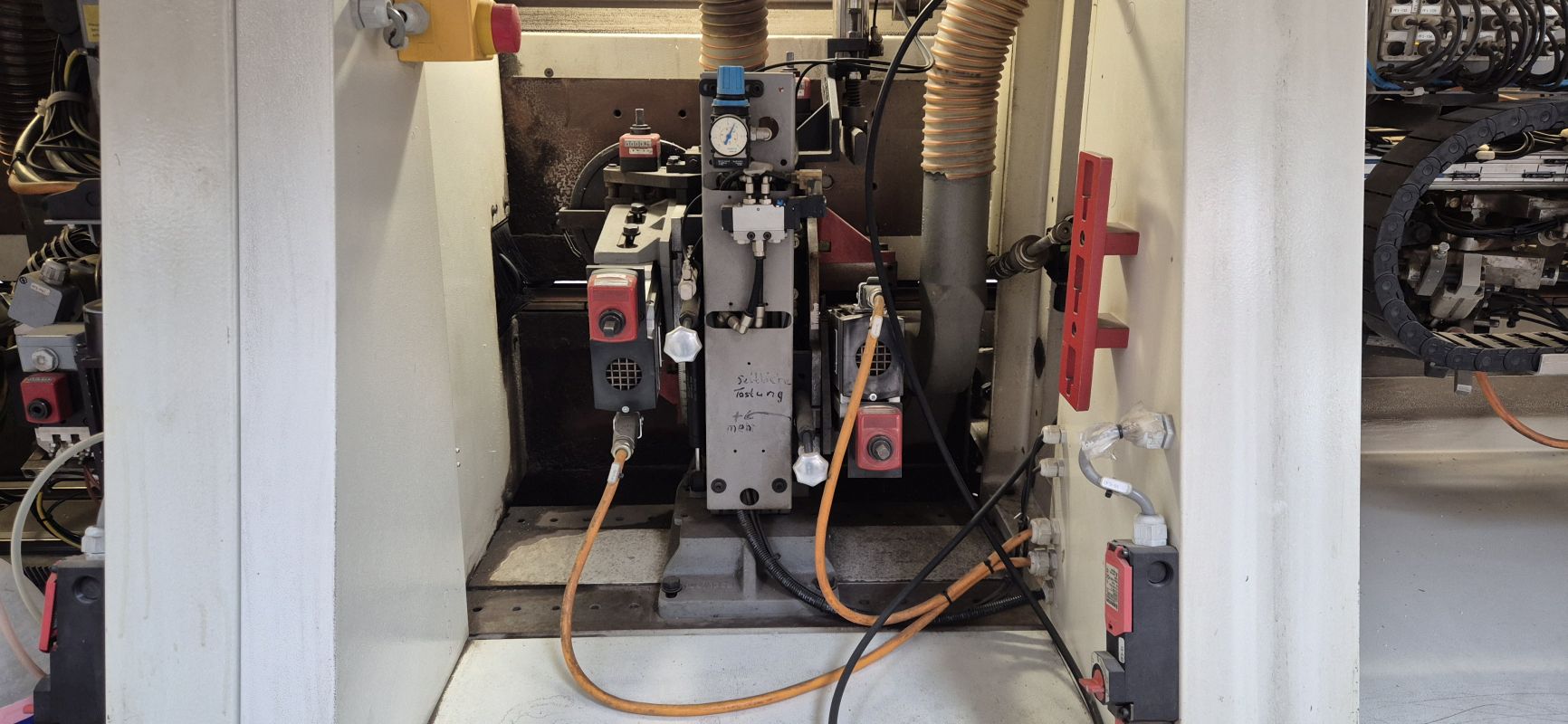

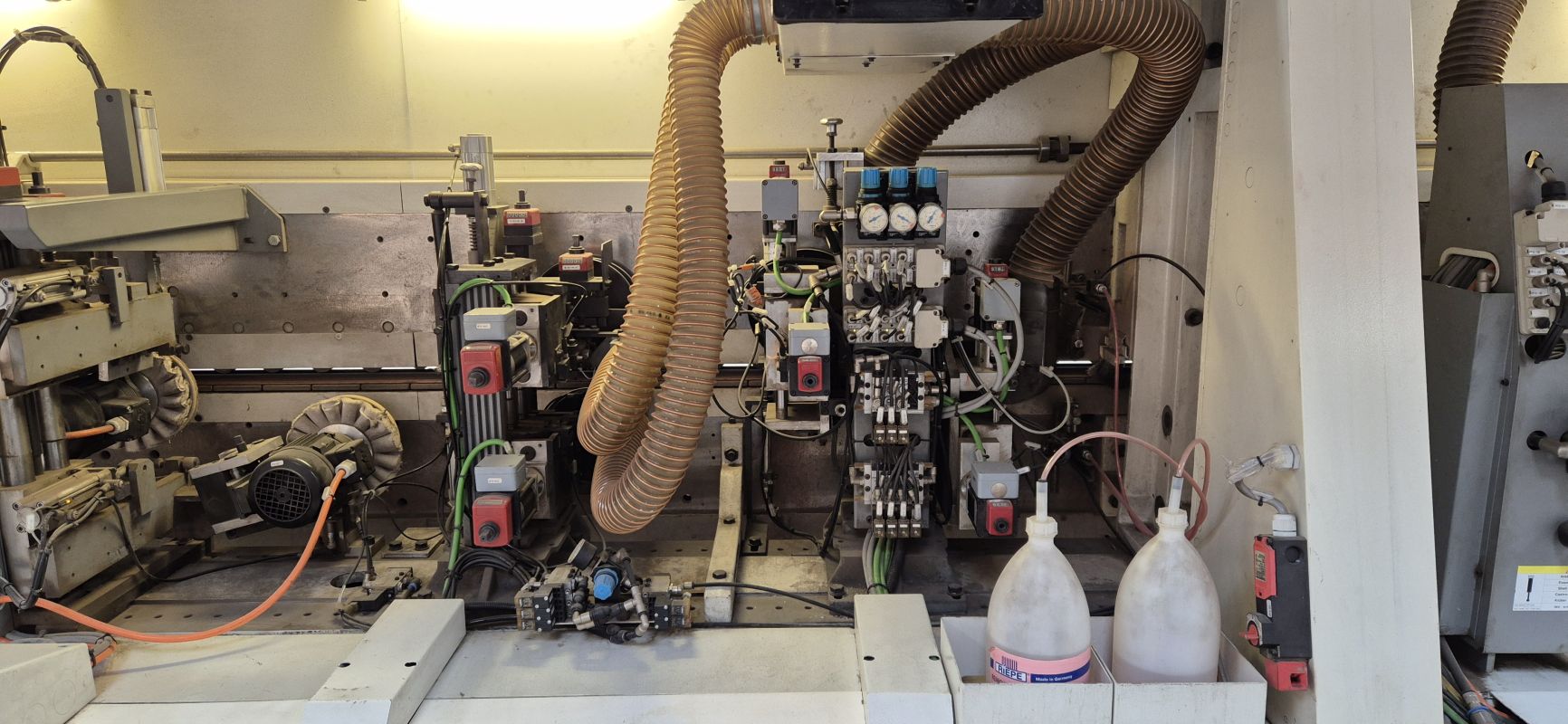

[b]Multi-functional processing unit 08.348

- For chamfering or radius milling of the top and bottom longitudinal edge, as well as copying of the front and rear corners of the workpiece

- Program-controlled conversion for up to 4 profiles

- 2 motors, each 660 W, 400 V, 200 Hz, 12,000 rpm

Spray nozzles top and bottom for applying cleaning agents

Multi-profile scraper unit

- With stepper motor axes for horizontal and vertical positioning

- For 4 profiles

Flat scraper unit

- With electro-pneumatic disengagement mechanism

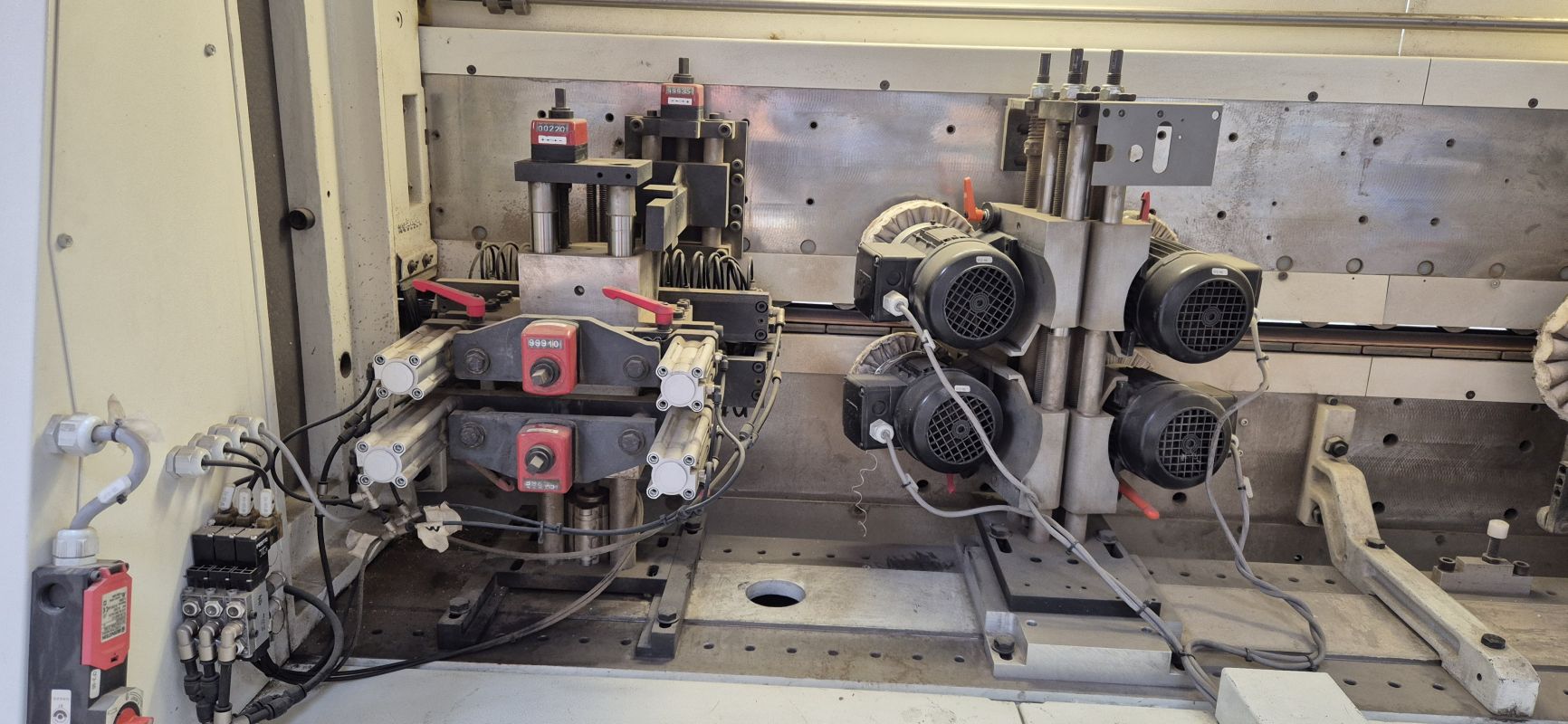

Copy buffing unit

- With 4 buffing motors, each 250 W

Buffing unit

- With 2 lower and 2 upper motors, each 180 W, 50 Hz, 1400 rpm

Smoothing unit

- For smoothing and eliminating white breakage on milled PVC/ABS edges

With one top and one bottom smoothing zone

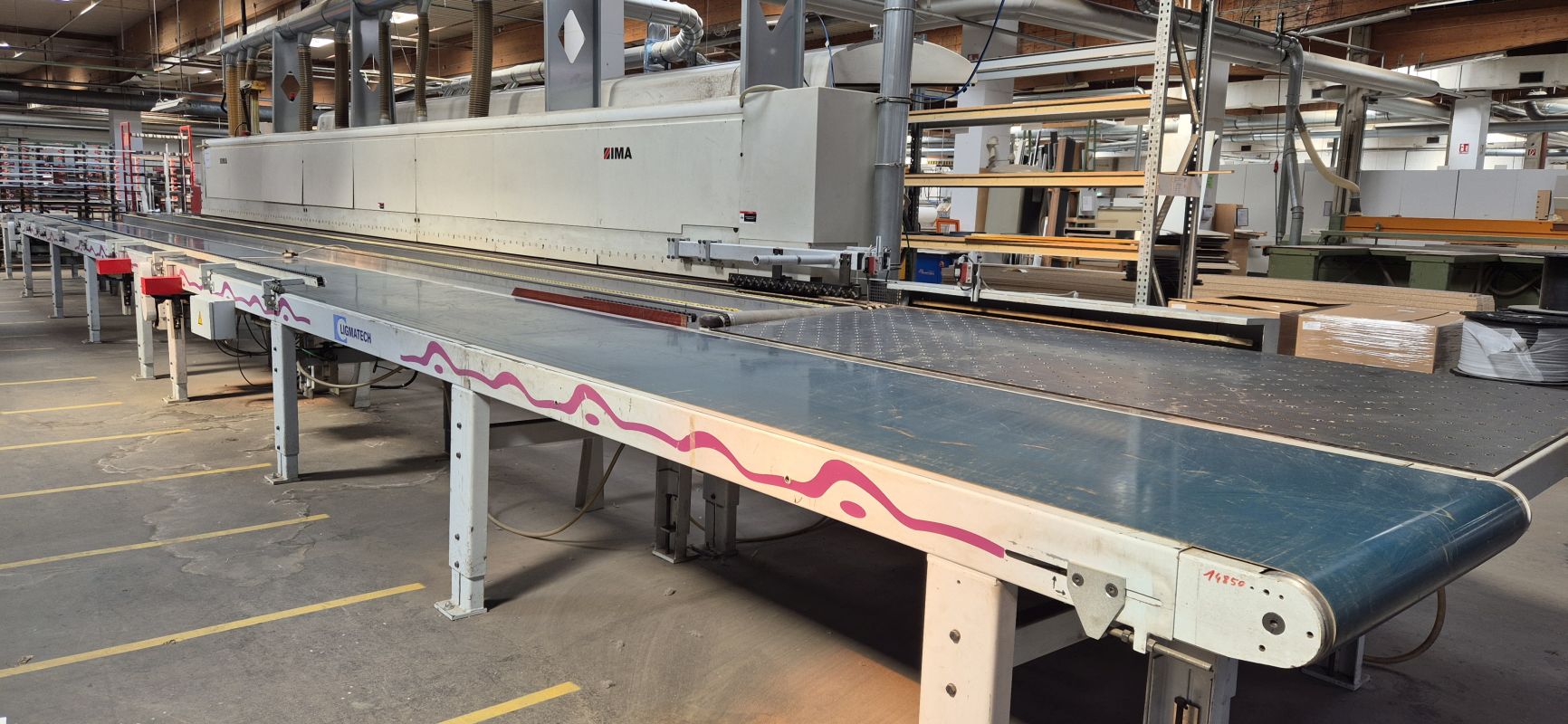

Workpiece return system LGIMATECH ZHR 05/L/145

- Inclined air cushion table, 2 return belts with bottom brushing units

Note:

The technical data and descriptions are transcribed from the original order confirmation. The information is for reference only and is not legally binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia