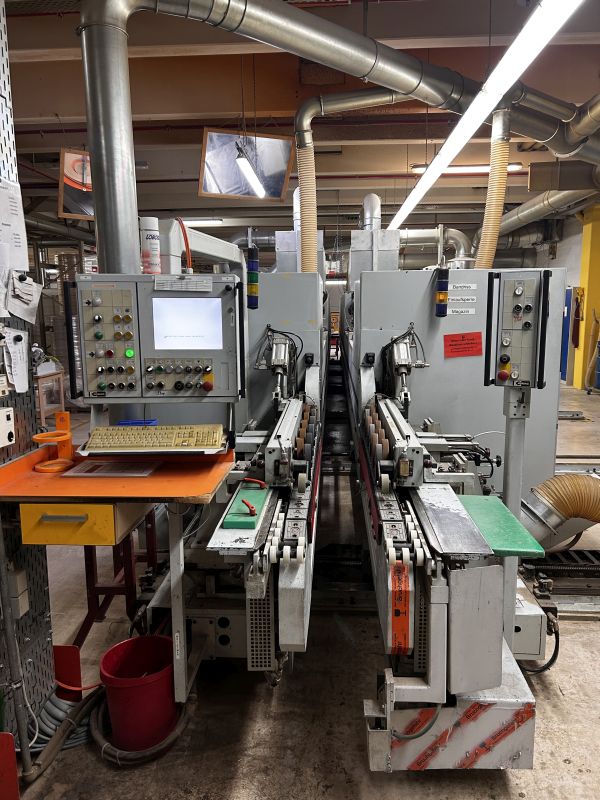

BrandHOMAG

typePROFI KFL20/29/QA/25

stateUsed

stock number0401722

year2003

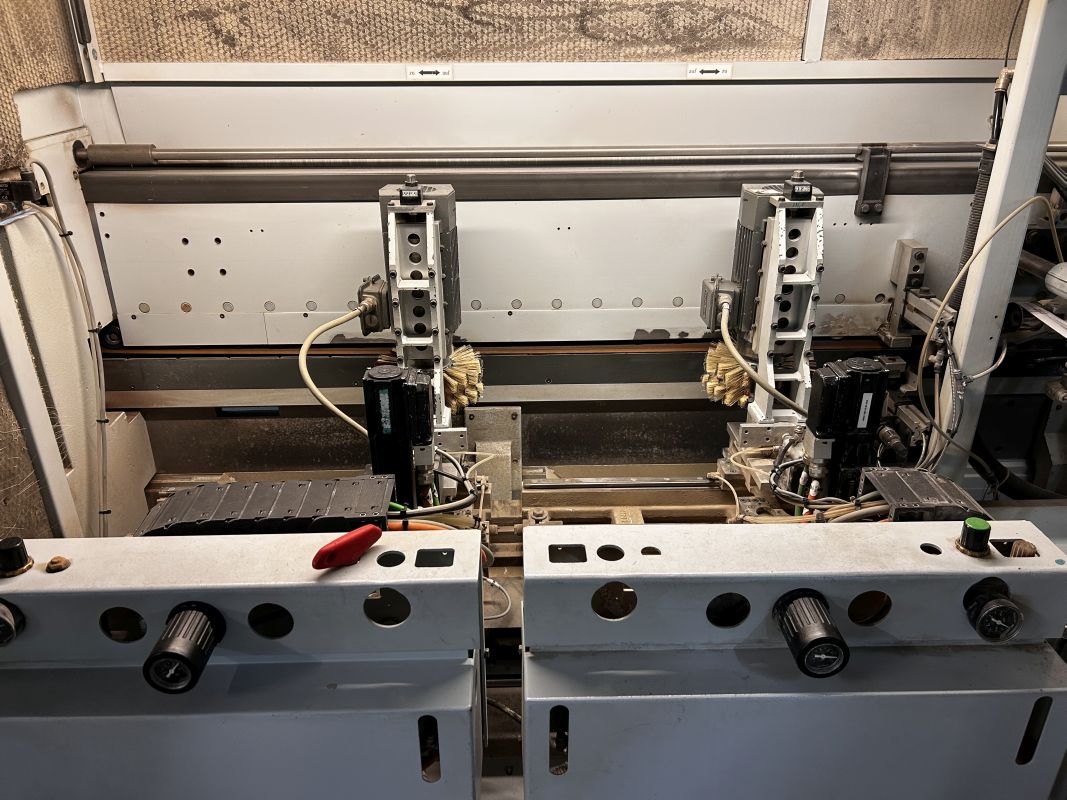

- Feed infinitely variable 10 - 40 m/min

- Workpiece protrusion 40 mm

- Workpiece thickness 8 - 60 mm

- Working height to top edge 950 mm

- Working width double-sided min. 240 - 270 mm

- Working width double-sided max. 2500 mm

Questions about this machine

used double-sided format processing and edge banding machine

Brand: HOMAG

Type: PROFI KFL20/29/QA/25

year 2003

Control NC21:

Technical data:

- Feed infinitely variable 10 - 40 m/min

- Workpiece protrusion 40 mm

- Workpiece thickness 8 - 60 mm

- Working height to top edge 950 mm

- Working width double-sided min. 240 - 270 mm

(depending on machine equipment)

- Working width double-sided max. 2500 mm

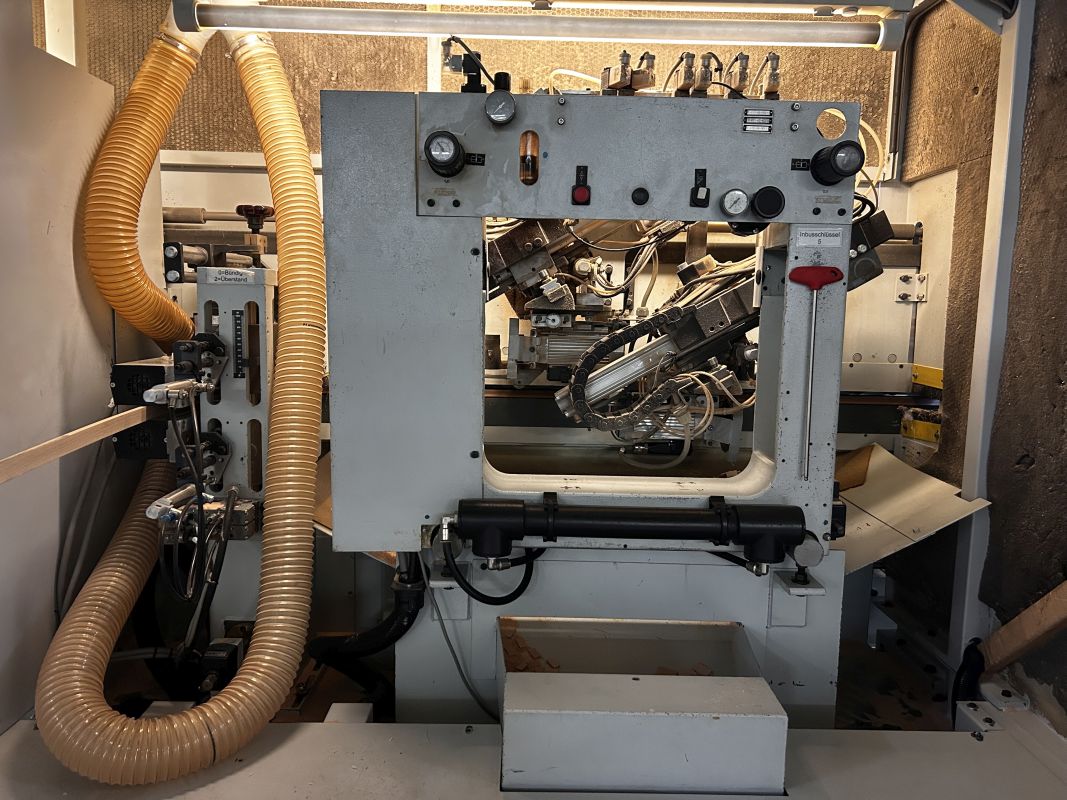

Infeed stop

Infeed guide

Stepless axis for infeed guide

Infeed device 10 rollers can be folded up

Electropneumatic folding up

Chain track extension machine II + 500 mm

Stop cam stepless

Cam pitch 500 mm

Compact - double tensioner lengthwise/crosswise 6,6KW 11

- 1 motor 4.5 kW, 100 Hz. , 6000 1/min

- 2 motors 6.6 kW each, 100 Hz. , 6000 1/min.

Stepless axis horizontal

Motor shaft D=40 for hydro clamping

Gluing unit A20 strips + 1 roller

- for processing strips up to max. 20 mm

- and rolls up to max. 3 mm

- Feed rate up to 40 m/min for thin edges up to 0.8 mm

- Feed rate up to 30 m/min for thick edges up to 3 mm

- Feed rate up to 25 m/min for strip material

- Hot melt adhesive unit A34

- Magazine A20 - 1 roll

- Pressure zone C

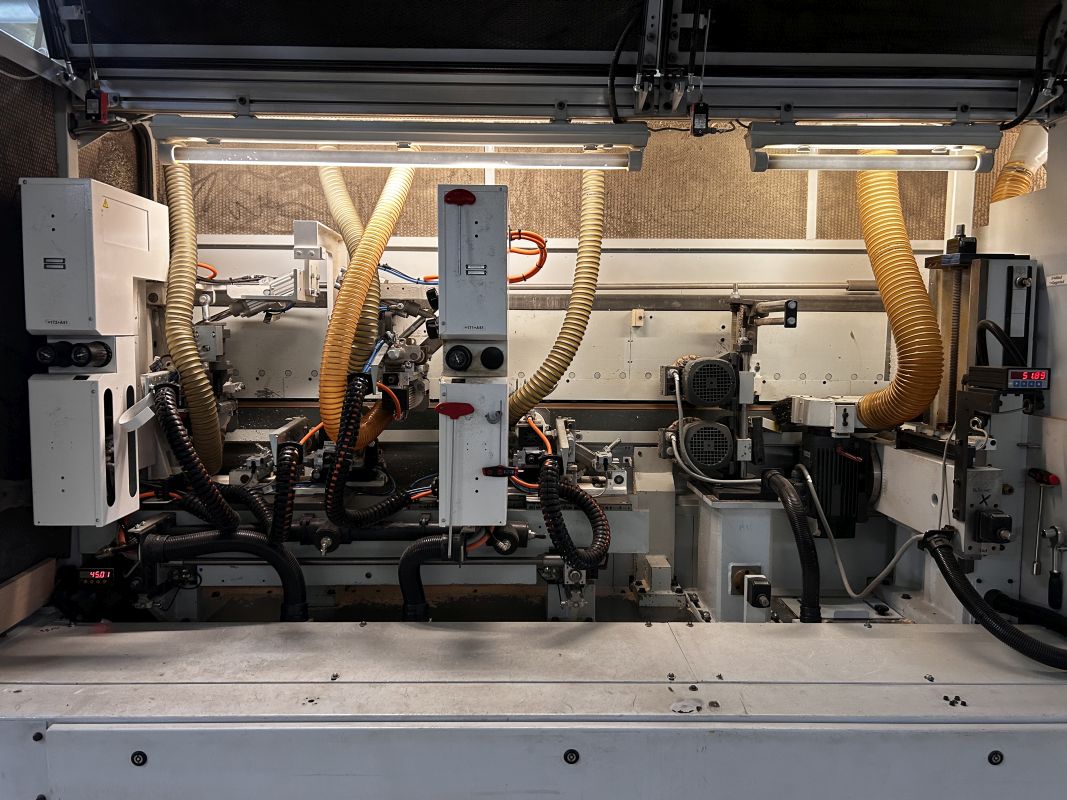

Snipping unit HL 05 bevel / straight

- 2 motors 0.4 kW each, 200 Hz. ,12000 1/min

- Feed speed max. 28 m/min

Pneumatic adjustment chop motor

- for electro-pneumatic adjustment of the snipping motors to 2 positions

- Position 1 - flush caps

- Position 2 - caps with overhang

Pre-milling unit top and bottom 1.5 KW

- 2 motors one above the other

- 1.5 kW each, 200Hz. , 12000 rpm

- manually movable sideways

Standard milling unit 4.0 KW

- 1 milling motor 4,0 kW 100Hz. , 6000 rpm

Buffing unit top and bottom

- 2 motors 0.25 kW each

- Inclined and height-adjustable

Shaping trimming unit FF32R/60 (equiped in 2019)

- for cross processing of postforming or softforming parts and for rounding plastic

of plastic edges on the front and rear edges of the workpiece at the top and bottom

Standard trimming unit pneumatic control 4.0 KW

- 1 milling motor 4.0 kW, 100 Hz. , 9000 1/min

Stepless vertical axis

Stepless horizontal axis

Belt sanding unit KS 10

- for sanding straight edges

Bevel/radius sanding unit bottom PS 41

- 1 motor 0.55 kW

Top bevel/radius sanding unit PS 42

- 1 motor 0.55 kW

Bevel sanding unit

- for sanding the front and rear edge

Note:

The technical data and descriptions are copied from the original order confirmation. Data is for information purposes only and is not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia