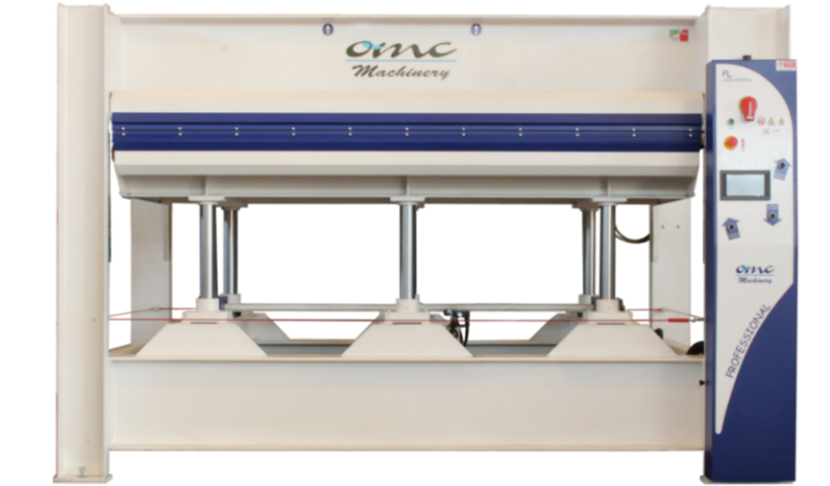

BrandOMC

typePL 90s

stateNew

stock number1110285

Plate size: 3000 x 1300 mm

Press force: 90 tons

Plate type: Elkom electronic plates

Questions about this machine

Hot platen press

Brand: OMC

Type: PL 90s

New machine

Technical data

Plate size: 3000 x 1300 mm

Stroke: 400 mm

Stroke type: Upward stroke (from bottom to top)

Plate type: Elkom electronic plates

Press force: 90 tons on 80% of the surface

Press cylinder: 6 x Ø 70 mm

Specific pressure: 2.05 kg/cm² on 100% of the surface, 2.56 kg/cm² on 80% of the surface

Loading and unloading side: 3000 mm

Heating system: Electronic 25.4 kW, maximum temperature of 120°C

Automatic opening with timer

Control panel: Standard

Connection: 400 V, 50 Hz, 3 ph

Safety device:

Safety cable around the entire press

Emergency button

Two-hand operation

CE standard

Press structure

The press structure is made of composite and welded steel. The structure of both the fixed and moving platen is made of composite and welded steel. The press is equipped with a rack and pinion guide system to ensure perfect parallel movement during the closing/opening of the plates.

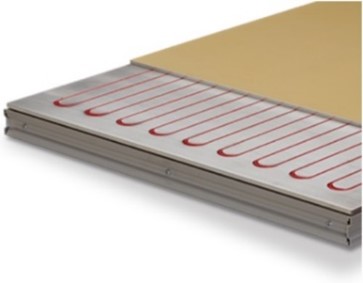

Elkom heating plate

Elkom electric plates with electric resistors

The plates consist of a chipboard on which an aluminum sheet with the electric resistors is mounted.

Maximum working temperature 120°C.

Maximum thrust = 7 kg/cm²

Hydraulic system

- The hydraulic system consists of a two-stage unit with submersible pump to reduce noise and lubricate the rotating parts.

- Pump for fast closing/opening (high flow rate - low pressure 35 l/min), press pump (low flow rate - high pressure 1.6 l/min).

- 2 HP electric motor

- The hydraulic unit is equipped with the following control/safety valves installed on the tank:

- Maximum pressure valve: prevents excessive pressure in the hydraulic system

in the event of an electrical or electronic control fault

- Pressure retention valve (check valve)

- Valve for low drain pressure (pre-drain valve). It prevents dangerous shocks

within the system.

- Oil drain magnetic valve

Control panel and electrical system

The pressing parameters can be set on the control panel, which is equipped with the following switches/meters:

- 2 temperature regulators for setting the plate temperature

- Pressure gauge for pressure regulation with automatic pressure equalization system

- General on/off switch

- Two manual safety buttons for closing the press

- Timer for automatic opening

- Switch to select manual or automatic opening of the platens after the work cycle .

- Off/on switch for upper and lower platen resistance

Safety systems

- Timed bimanual control for closing the press

- Safety rope on the four sides of the press

- Platen lock for maintenance

- Protective guards for the pinion and rack units

- Safety stickers and warning notices

- Operating and maintenance manual

- The press complies with CE standards

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia