BrandWEHRMANN

typeIMA COMBIMA

stateNew

stock number0031133

year2025

- reconditioned edge banding machine for industrial furniture production.

- Double-sided longitudinal and transverse processing with joining, gluing and finishing of edge material.

Questions about this machine

New edge banding machine IMA COMBIMA for industrial furniture manufacturing.

Double-sided longitudinal and cross processing with jointing, adhesive application, and post-processing of edge material.

Automatic Processing:

Automatic complete processing of veneer/plastic strips supplied as roll material with thicknesses ranging from 0.4 to 3 mm.

Feed Rate:

Program-controlled feed speed between 10 and 40 m/min.

Transport Chain:

Rolling transport chain with 40 × 40 mm cams and a pitch of 540 mm.

Component Guidance:

Upper pressure system using a 32 mm wide V-belt for optimal and gentle guidance of components.

Processing Units:

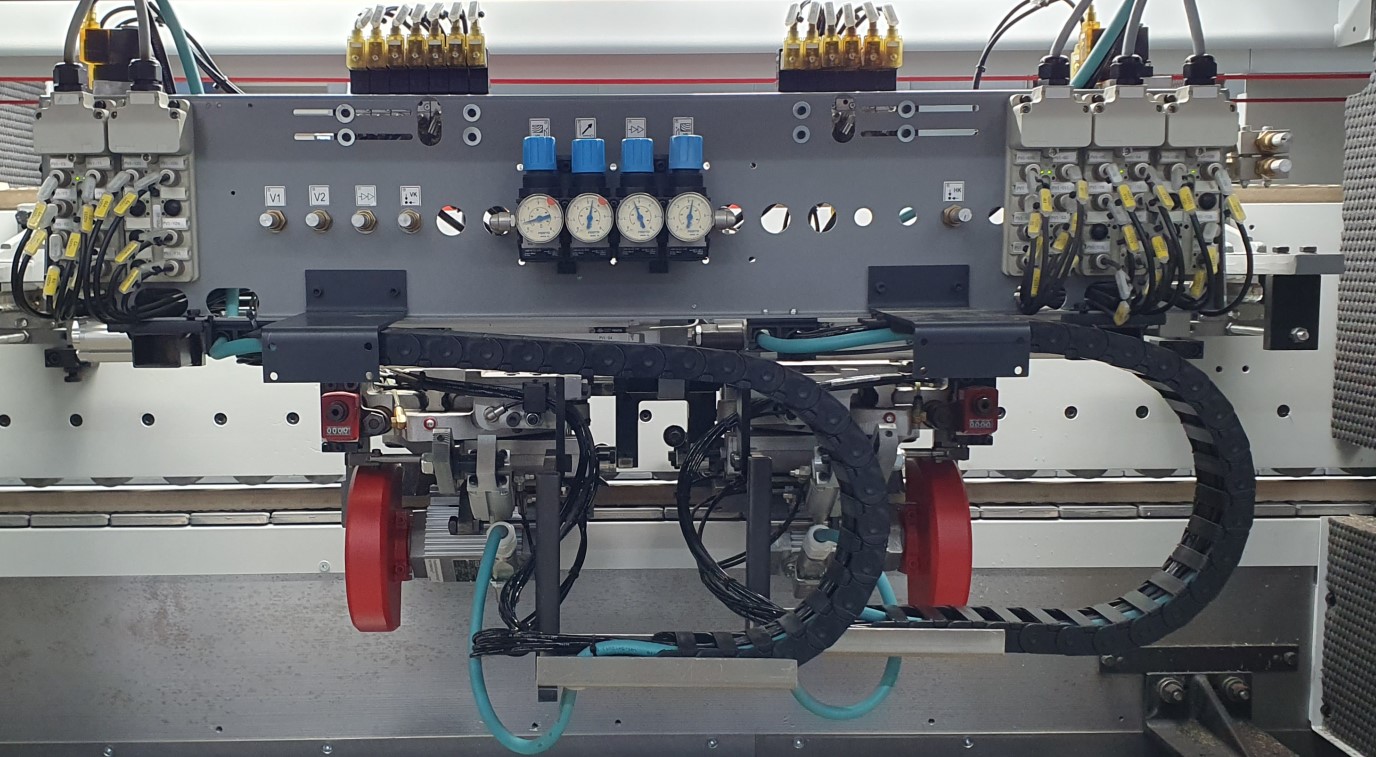

Adhesive dispensing and processing modules (e.g., IMA trimming and KFA technology).

Control System:

BECKHOFF control system featuring a modern industrial PC with a 21.5-inch monitor that supports touch, keyboard, and mouse operation.

Flexibility:

Flexible machine configuration (the arrangement of modules can be selected freely).

Typical Configuration per Side:

Working Area:

Working width approximately 270 – 2800 mm, with center support and central lubrication.

Chain Extension:

Chain conveyor extension with a feed mechanism.

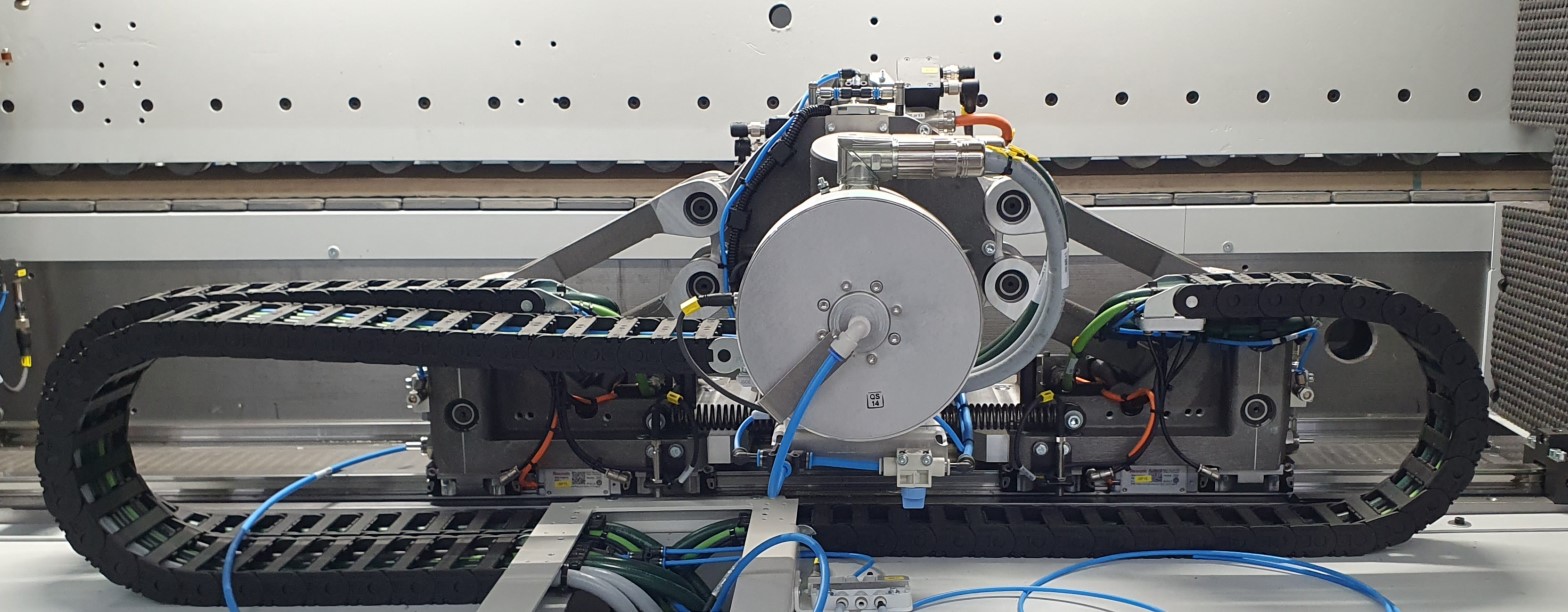

Format Unit:

Joint Milling Machines: Two units equipped with 2 motors each (4.5 kW, 400 V, 150 Hz, 9000 rpm, frequency controlled).

Double Milling Heads: Two motors with hydraulic shafts (6.6 kW, 100 Hz, 400 V, 6000 rpm, frequency controlled).

Banding Unit:

Equipped with a Hardo pre-melter (5 kW) alongside an adjacent storage tank.

Features a 24-position edge magazine for maximum flexibility with both thin and thick edges.

Trimming Unit 08.042

(Max. processing speed: 30 m/min):

Driven by 2 motors (200 W, 400 V, 200 Hz, frequency controlled).

Capable of producing trimming cuts that are either flush or beveled.

Multi-Profile Milling Unit 08.0578:

Equipped with 2 motors (2 × 660 W, 400 V, 200 Hz, frequency controlled), with a swing capability of up to 30°.

Contour Milling Unit 08.355 KFA X30

(Max. processing speed: 30 m/min):

Driven by a single motor (500 W, 400 V, 400 Hz, 18,000 rpm).

Finishing Post-Processing:

Multi-Profile profile scraper 08.516:

Features stepper motor axes for horizontal and vertical positioning.

Flat scraper 08.521:

Provides electronic horizontal positioning.

Oscillation buffing unit:

Equipped with 2 motors (0.55 kW, 50 Hz, 380 V).

Grooving Unit:

Driven by one motor (6.6 kW, 400 V).

Additional Information:

- Fully rebuilt machine with CE certification and 1 year warranty.

- Other customer-specific equipment configurations are possible.

- Delivery time: Approximately 6 months.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia