BrandHOMAG

typeKFL526/C

stateUsed

stock number0401812

year2006

Workpiece dimensions

- workpiece thickness: 12 - 40 mm

- workpiece size (L/W): min 250 x 240 mm, max. 2500 x 1200 mm

- workpiece weight: max. 50 kg

Questions about this machine

double-sided edge banding machine

Brand: Homag

Type: Optimat KFL 526/C

Year of manufacture: 2006

technical data

Workpiece dimensions:

- workpiece thickness: 12 - 40 mm

- workpiece size (L/W): min 250 x 240 mm, max. 2500 x 1200 mm

- workpiece weight: max. 50 kg

Edge dimensions:

- edge thickness roller material: 0,4 - 3 mm

- edge cross section plastic edges: max. 135 mm²

- edge cross section veneer: max. 100 mm²

- roller diameter: max. 830 mm

Performance data:

- feed longitudinal processing

up to max. 35 m/min for thin edge up to 0,6 mm

up to max. 30 m/min for thick edge up to 3 mm

- feed in case of cross processing

up to max. 30 m/min for panel sizing

up to max. 20 m/min for edge processing

- workpiece gap: min. 500 mm

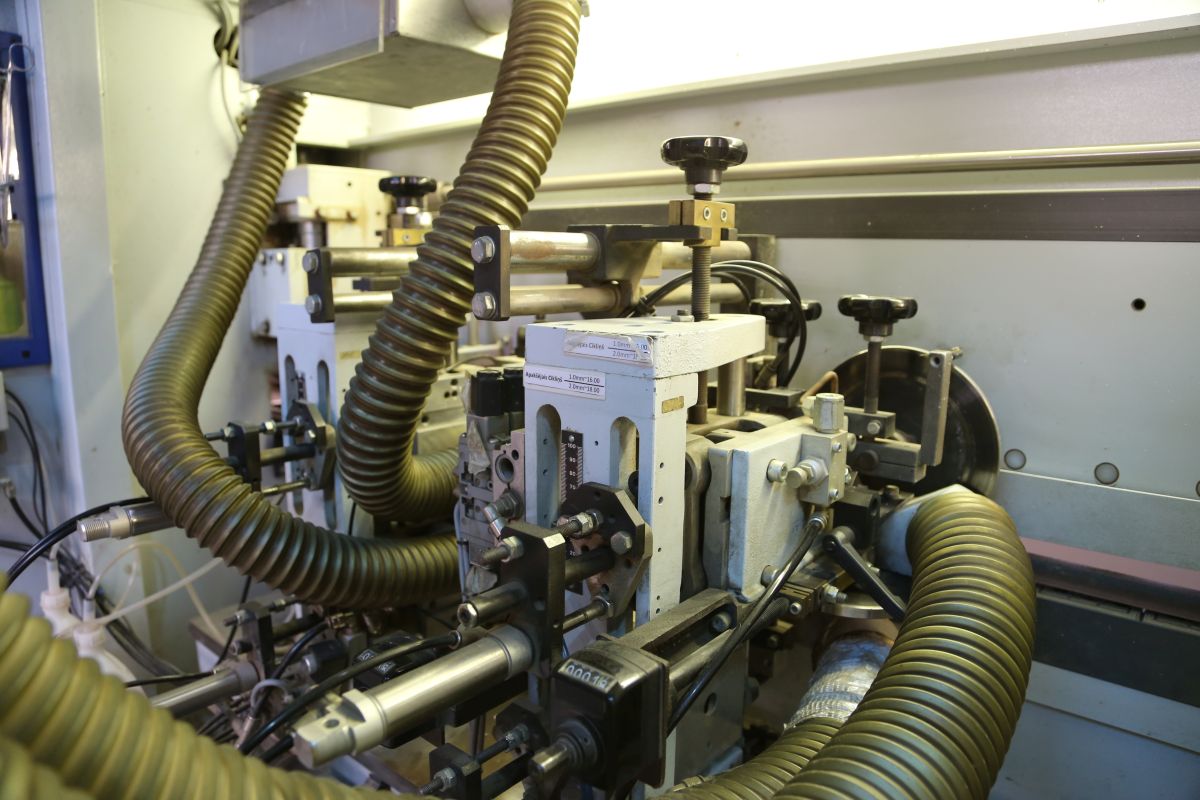

Infeed Individual machine one level manual

- workpiece infeed longitudinal: on the infeed fence

- workpiece infeed crosswise: before the cam

Intermediate transport at the outfeed

- 400 mm long

Seperating agent spray device on top/bottom

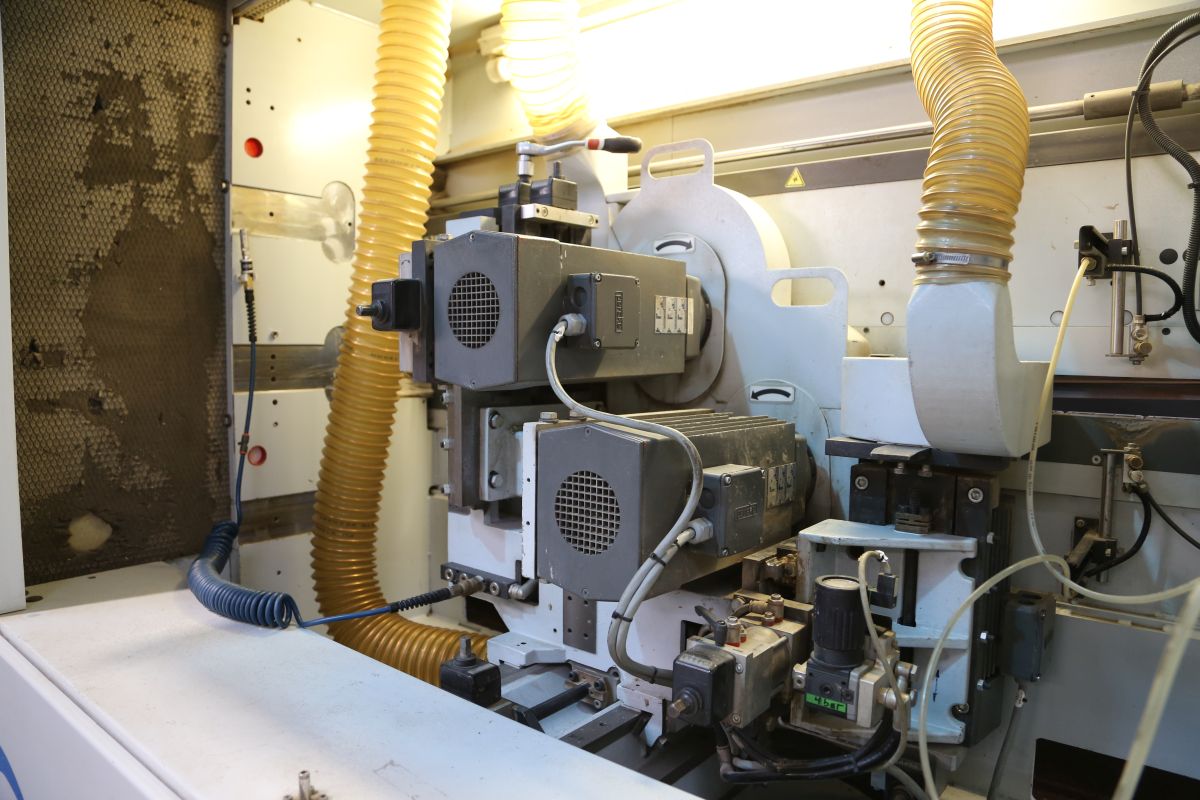

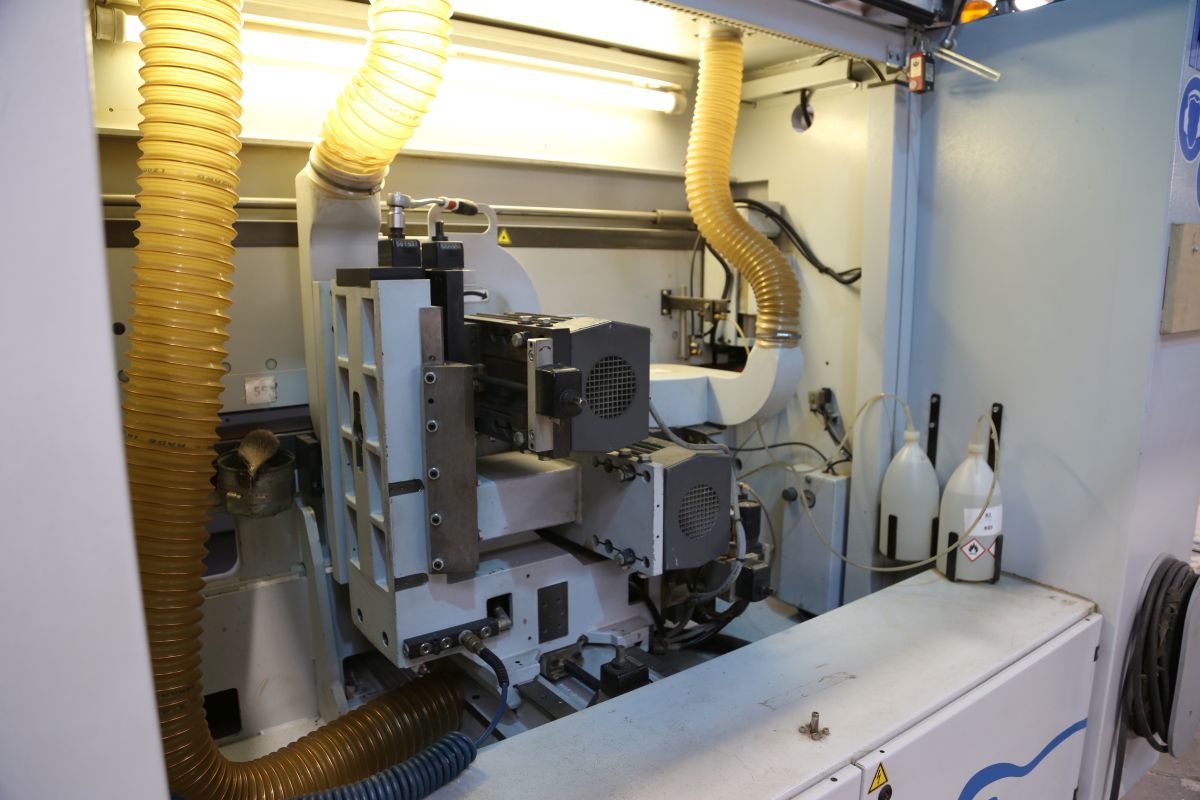

Double Hogger Longitud/Cross 6,6 kW KD11

- 1 motor 4,6 kW, 100 Hz, 6000 rpm with electropneumatic control

- suction hood I-system for tool diameter 180 - 200 mm

- 2 motors each 6,6 kW, 100 Hz, 6000 rpm

- incl. suction hood I-system for tool diameter 220 - 250 mm

Gluing Unit A3 - 2 rolls

Profile trimming unit FF12 on top/bottom

- 4 motors each 0,4 kW, 200 Hz, 12000 rpm

Scraping unit profile PN20

Finish Unit FA11 on top/bottom KFL/C

Stepless stop cams

- cam projection max. 25 mm

- Nockenabstand 500 mm

Standart trimming unit SF20 6,6 kW Finishing

Rough trimming unit 0,55 kW

Optional at extra cost:

- PUR Nordson melting station

- Tool set

- Suction tube

Note:

The technical data and descriptions are transcribed from the original order confirmation. The information is for reference only and is not legally binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia