BrandIMA

typeNovimat Concept/I/G80/440/R3

stateUsed

Price (plus VAT.)€ 59000

stock number0401767

year2006

New control system in 2020

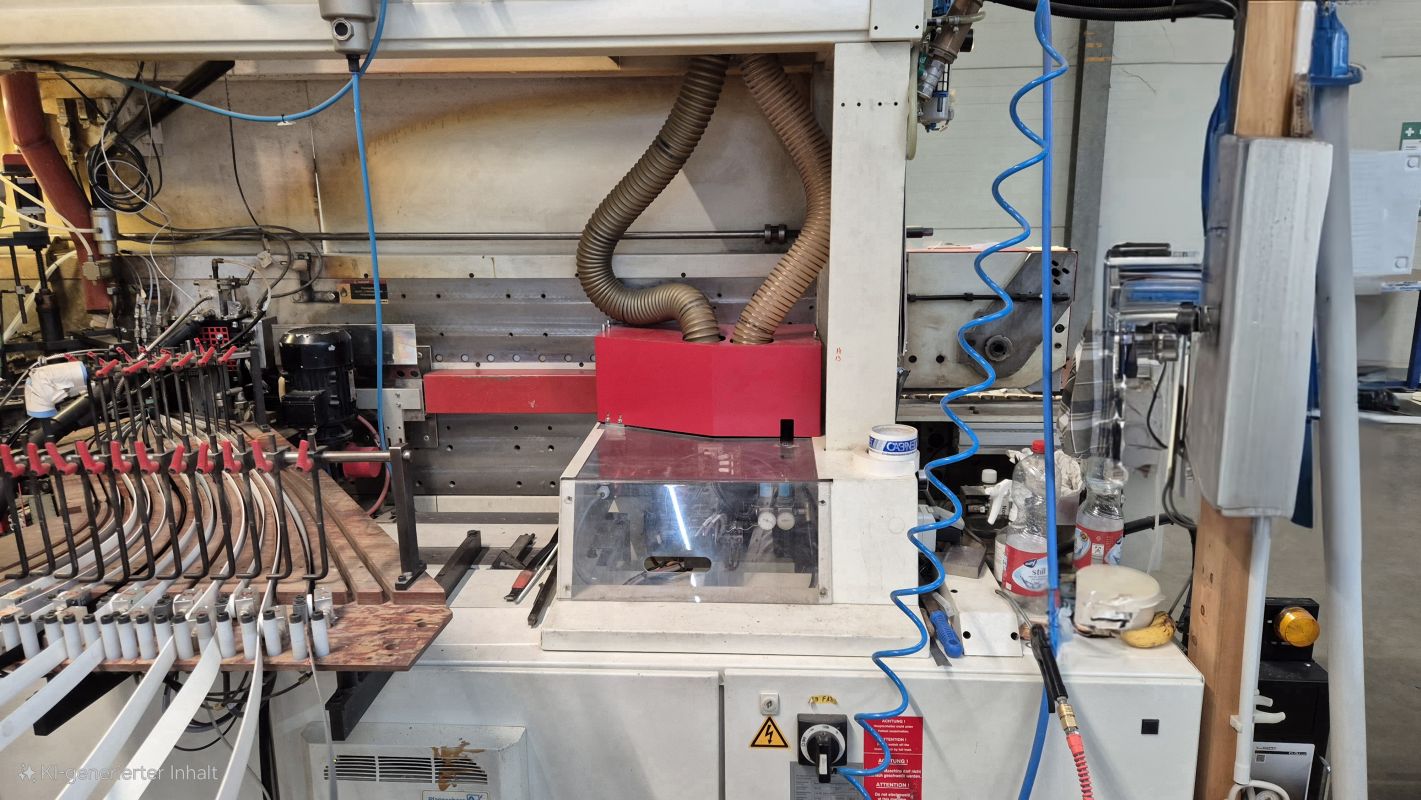

Premilling unit

Gluing unit PU + HOT-AIR with 12-coil magazine

Endtrimming unit from top

Roughmilling unit top and bottom

MFA - contour milling unit with 2 motors

Profile scraping unit

Edge finish brushing unit LCM

Grooving aggregate pneumatic in/out

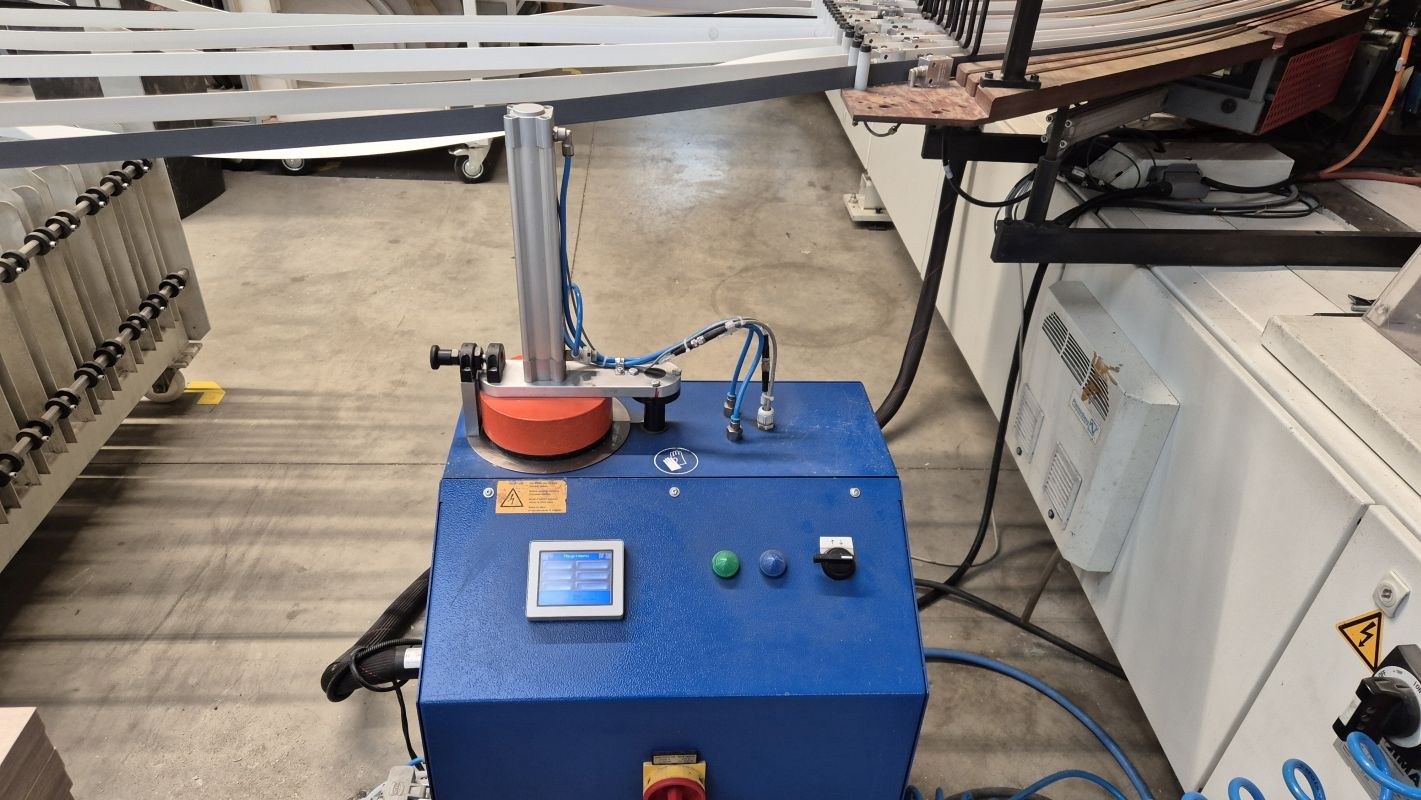

Inclusive LIGMATECH returning device with Wandres belt-cleanig unit from bottom

Questions about this machine

single sided Edgebanding machine

Brand: IMA

Type: NOVIMAT Concept / I / G80/440 /R3

Year 2006

Technical Data

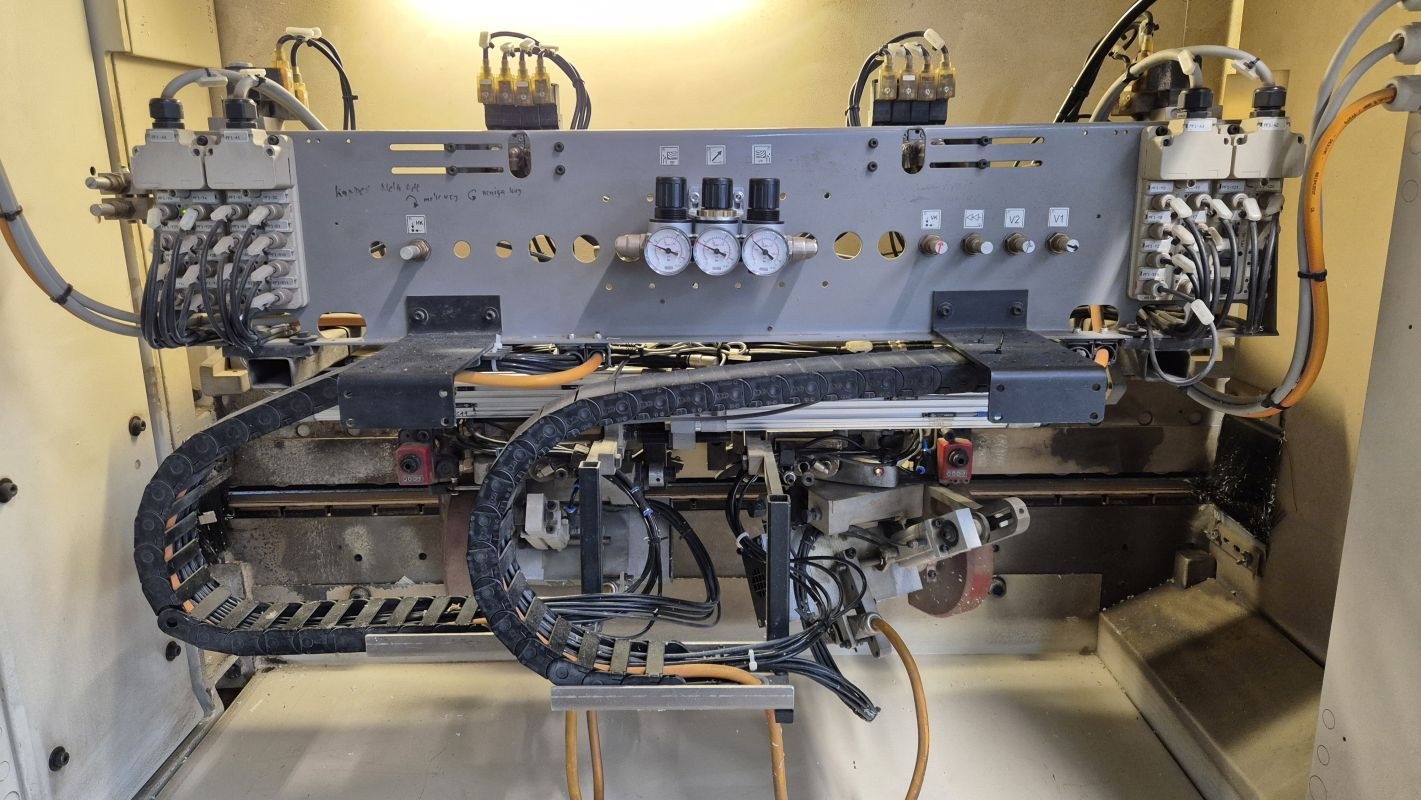

With new IMA control from 2020

Inlet with stop ruler adjustable via axis

Insertion table for the safe insertion of parts across the flow direction.

With controllable stop ruler for angular positioning.

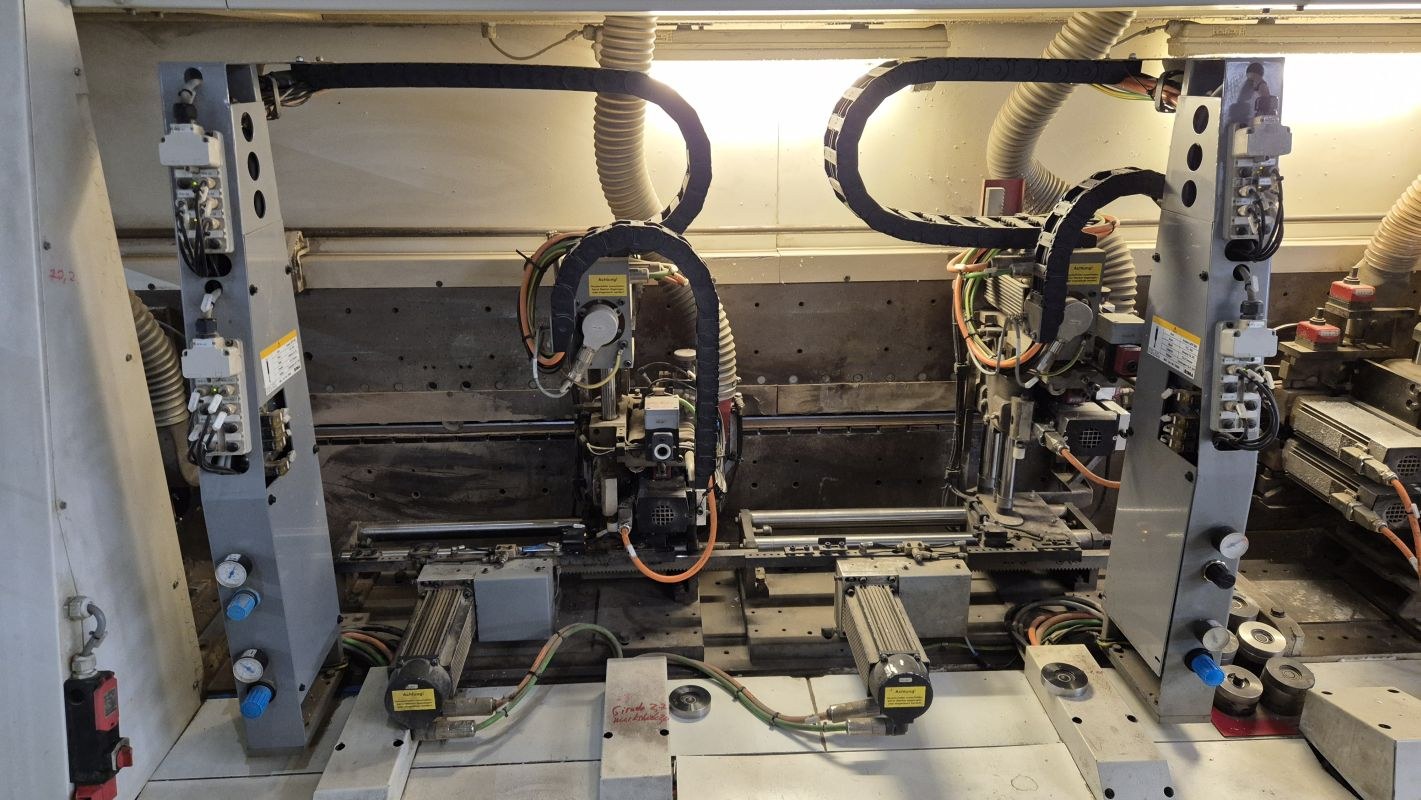

Joining milling unit with 2 motors each 4.5 KW, 150 Hz, 9,000 rpm.

Pneumatically controllable, horizontal adjustment via axis.

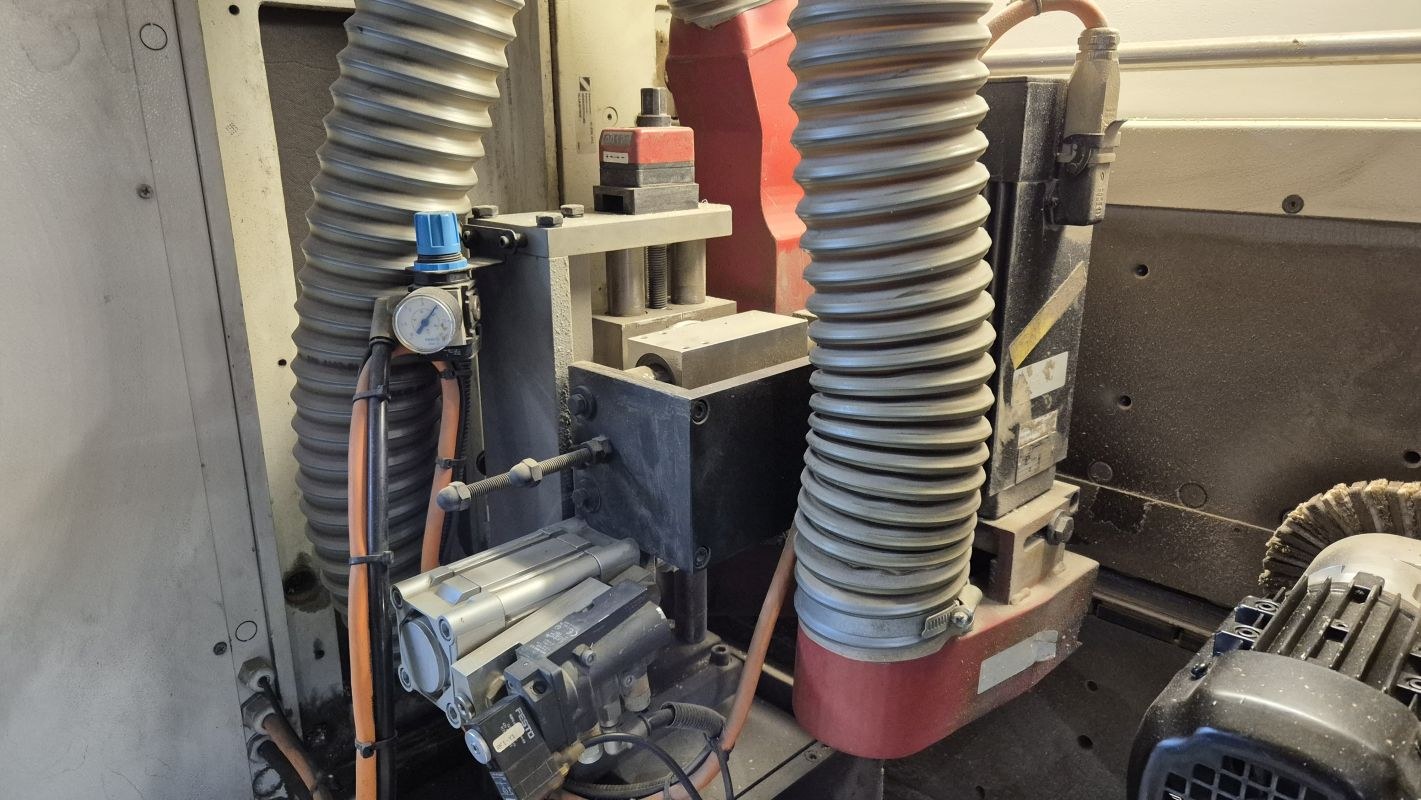

300 mm radiators for preheating the edge, 2 x 1.5 KW

Gluing unit for driving with PU glue - with pre-melting device

or hot-air system for laser edges

Roll materials 0.3 - 3.0 mm

With 12-fold edge magazine and vertical roll holders

End trimming unit working from top with 2 motors each 0.66 KW, 200 Hz

With pneumatic swivel 0+25°

Rough milling unit with 2 motors each 1 KW, 200 Hz

LCM Cleaner unit with spray nozzles above and below

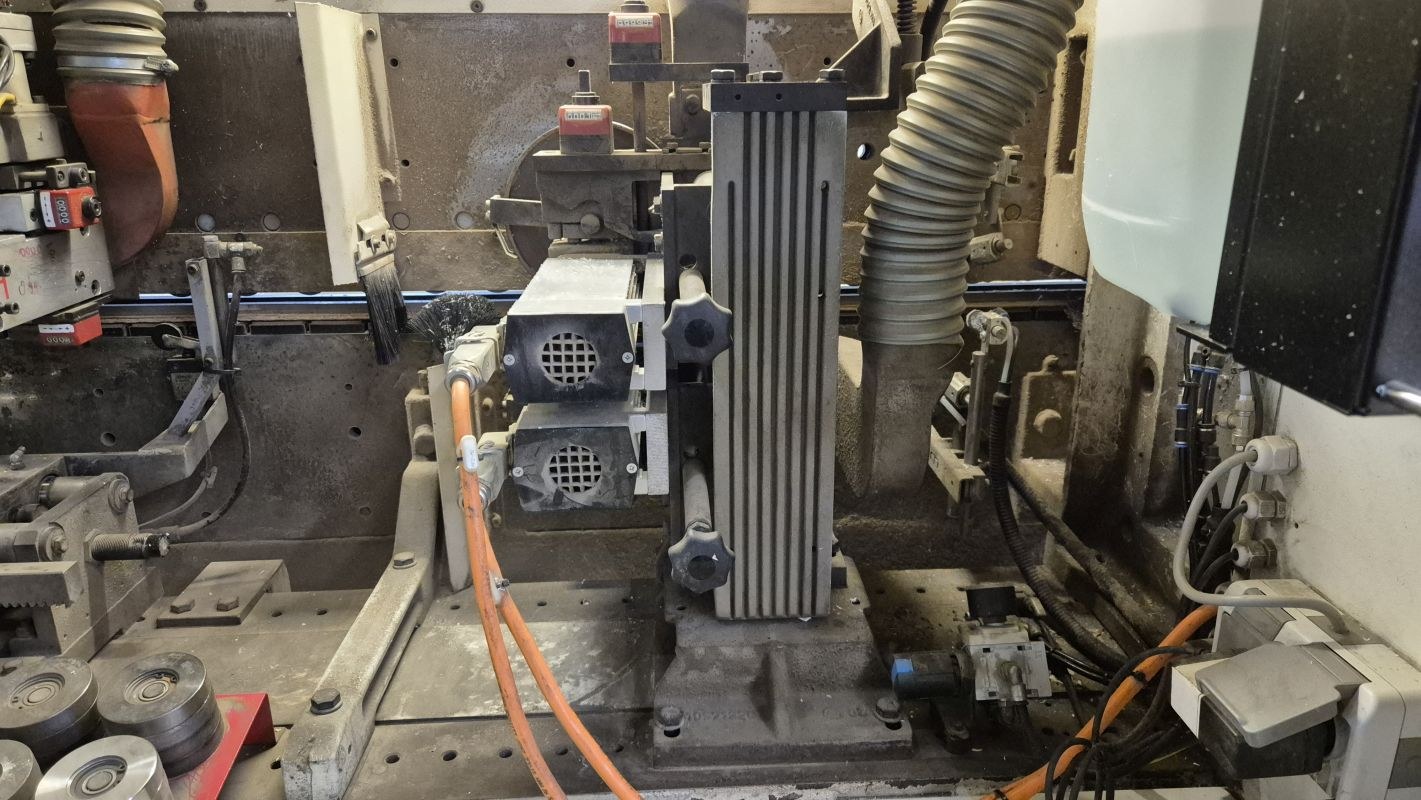

Multiple radius milling unit for chamfering or radius milling of the upper and lower longitudinal edges, as well as for copying the front and rear workpiece corners.

The horizontal and vertical aggregate movements take place

using servo drives.

With 2 motors each 0.6 KW, 200 Hz, 12,000 rpm.

Adjustment axis for horizontal motorized positioning

of the motor for automatic program change (radius/bevel)

and for fine-tuning the MFA.

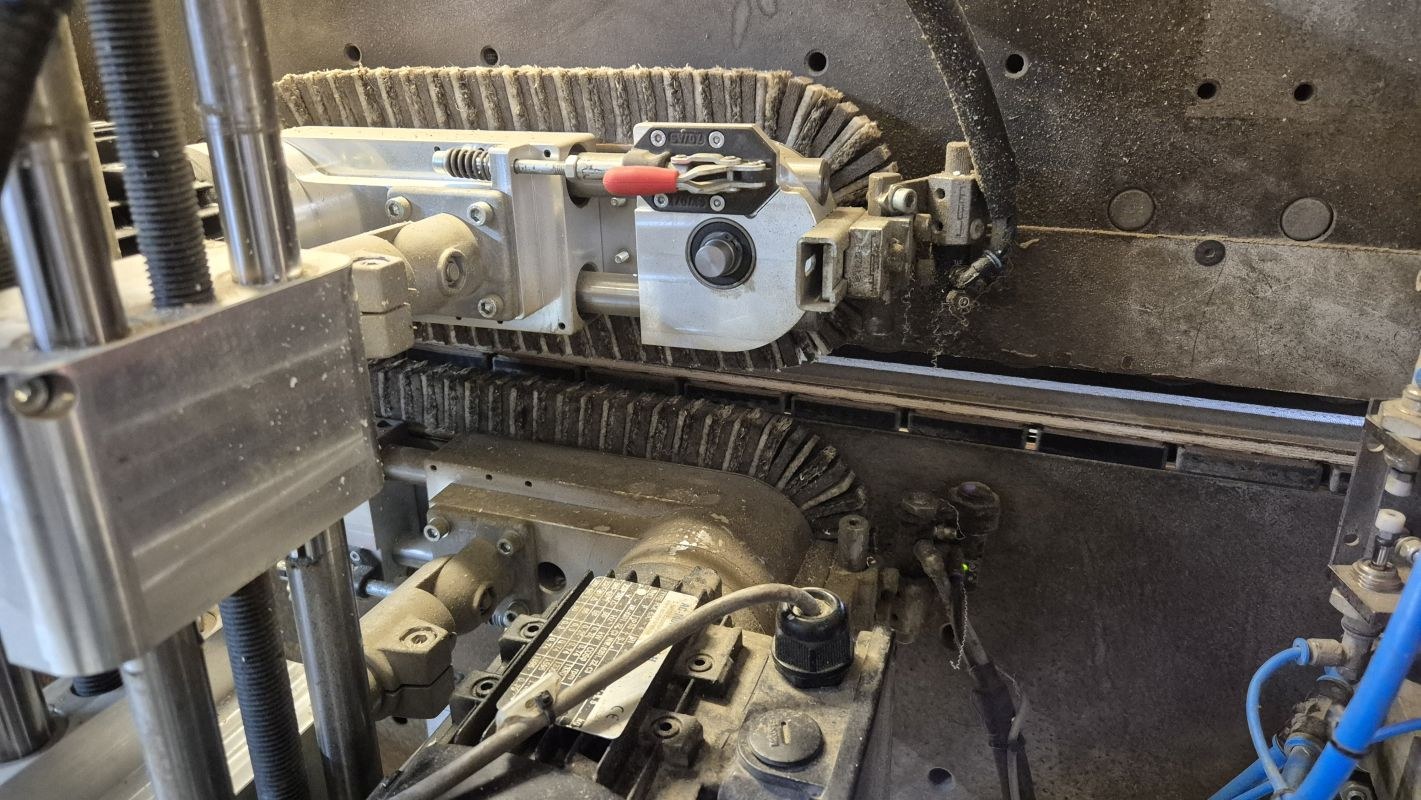

Profile scraper unit

For re-scraping an upper and lower milled

Quarter-circle profiles on glued-on plastic edges.

With manual horizontal adjustment with

mechanical digital displays.

Flat scraper

for removing hot melt adhesive residues from the edge area

of workpiece top and bottom, with height scanning ,

2 cutting plates, double sensing roller, single extraction nozzle

and blow-off nozzles .

With electronic horizontal positioning

LCM edge cleaning unit with one upper and one lower

driven longitudinal cleaning unit. With controlled nozzle application

Grooving / Milling unit

for milling continuous lateral or lower

Grooves, rebates or profiles, 1 motor 3.0 KW, 200 Hz, 12,000 rpm.

LIGMATECH return[b] with rake angle transfer for a gentle transfer.

Conveyor belt with additional roller support on the left long side ( foldable )

Extensive retrofits in recent years ( chain / top pressure / control and computer / cabling / automatic surface scraper etc. )

[b]Note:

The specifications and descriptions are a copy of the order confirmation at that time. Data are for information and are not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia