BrandIMA

typeCOMPACT PC-6220 F

stateUsed

Price (plus VAT.)€ 15500

stock number0030411

year2000

workshop-checked with:

- new transport chain

- new top pressure

- rebuilt edge magazine including gluing unit

Price 15,500 EUR

Questions about this machine

Single sided edge banding machine

Brand: IMA

Type: COMPACT PC-6220 F

Year: 2000

Left hand machine

Workpiece transport via a driven transport chain and adjustable top pressure

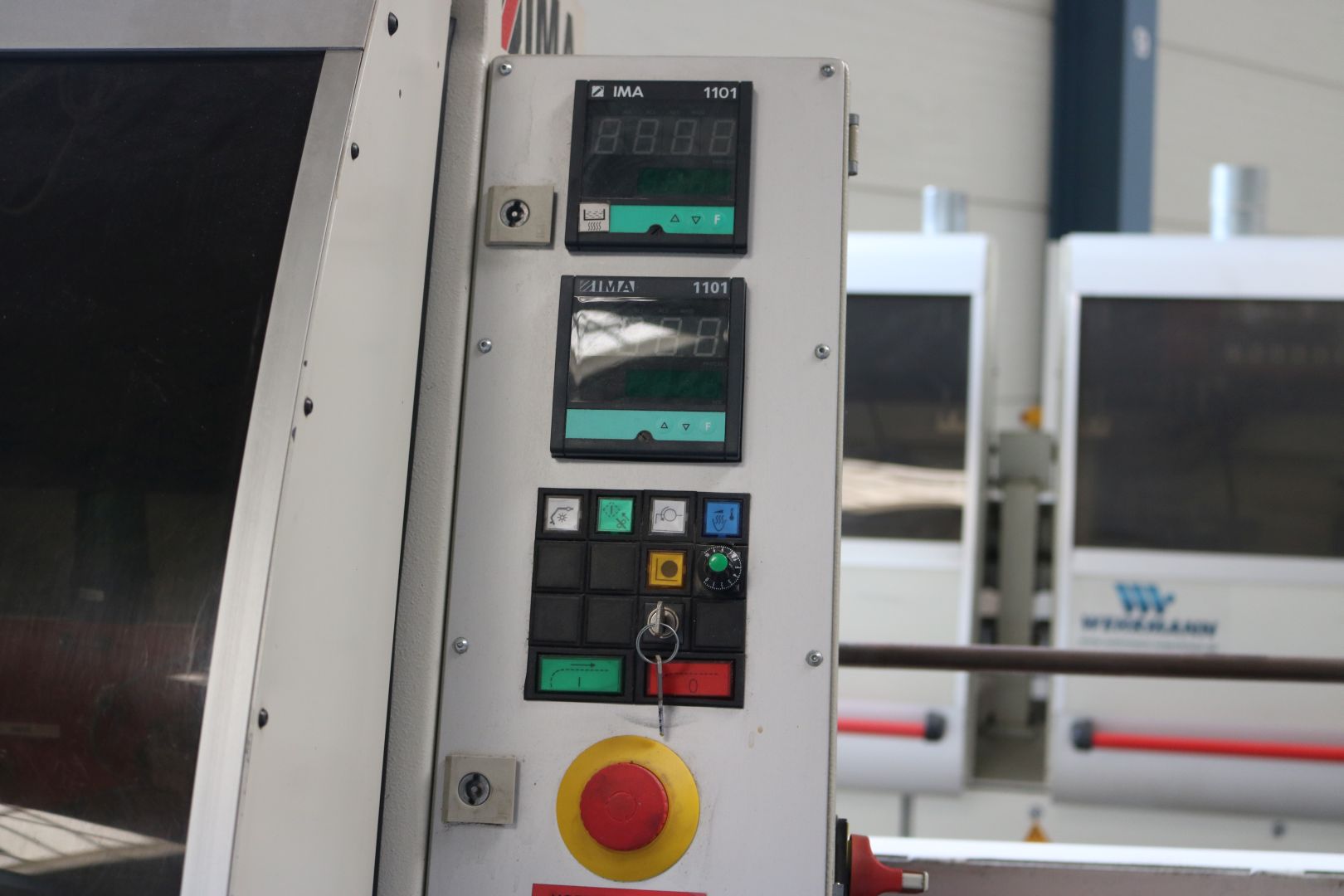

Beckhoff control

Need of space LxWxH mm: 7400x1500x2000mm

Weight: approx. 3600kg

Technical data:

Edge material:

a) Veneer/coil and strip ware,

b) PVC/coil and strip ware

c) Solid wood strips

min. edge height = approx. 14 mm

max. edge height = approx. 55 mm

min. edge tickness = approx. 0,4 mm

max. edge thickness = approx. 20 mm

min. panel thickness = approx. 10 mm

min. panel thickness = approx. 16 mm at use of the multi function unit

max. panel thickness = approx. 50 mm

min. panel width = appprox . 60 mm

min. panel length = approx. 150 mm

max. strips = approx. 20x50 mm

Panel supernatant from the chain conveyor = approx. 35 mm

Pneumatic connection: approx. 7 - 8 bar

The basic machine of the IMA-COMPACT-PC consisting of:

- Drive for the workpiece transport via mechanical controllable gear motor, feed speed approx. 8-20 m/min. (not the same as the working speed)

- Conveyor chain (80 mm wide + 60 mm long chain plates)

- Top pressure equipped with: 2 rows of rubber coated rollers, height adjustment (approx. 50 mm) central via handwheel

- IMATRONIC 121 SPS control with central unit and control panel; brand Beckhoff

- Movable supporting rail approx. 700 mm for wide workpieces

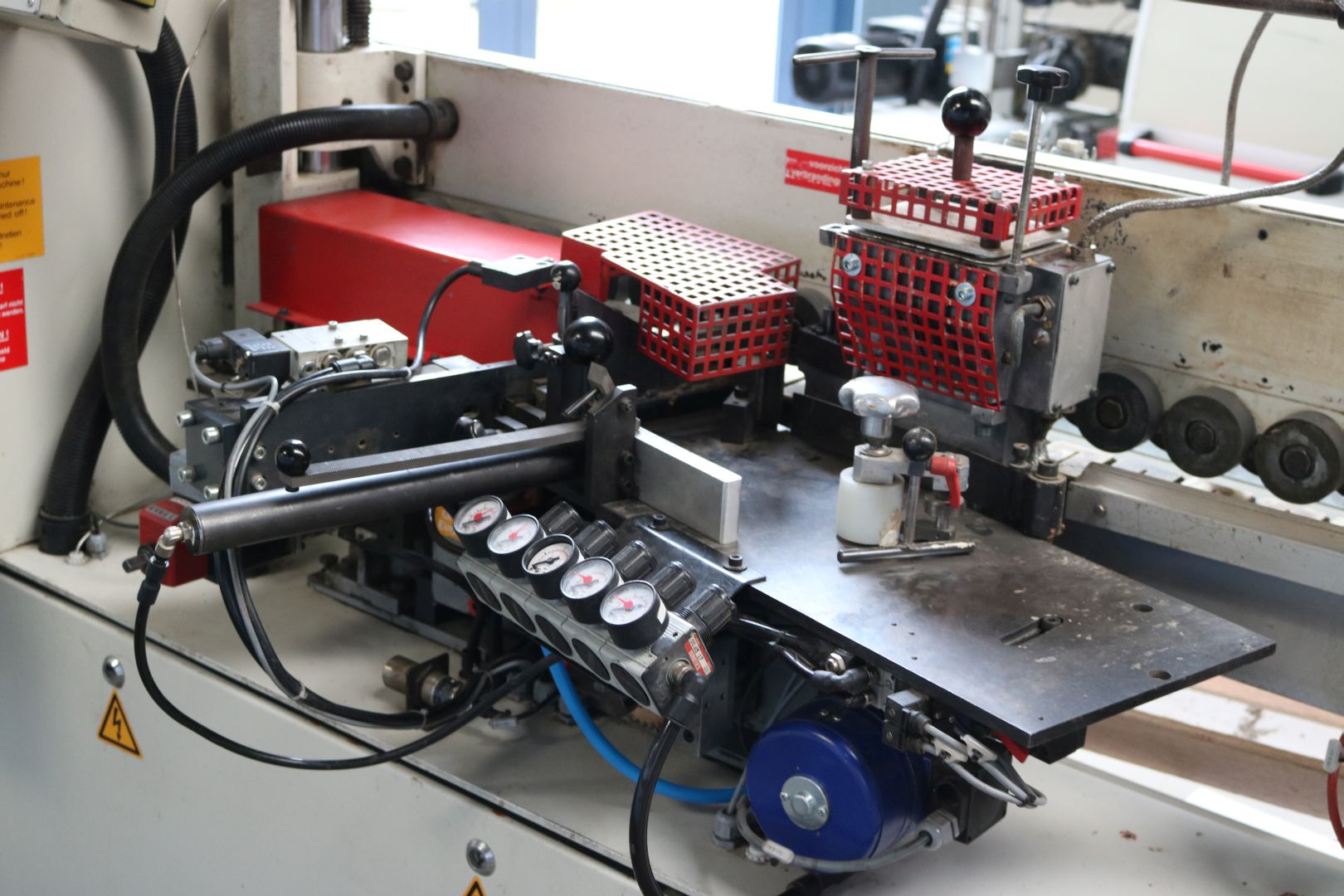

Adjustment via NC axis: horizontal adjustable, unheated infeed fence, pressure zone, flush milling, multi function unit, profile scraper

Pre-milling unit with 2 motors á 3 kW, 400 V, 200 Hz, 12000 rpm, working flow in working and counter working direction, with blowing nozzle for the removal of loose particles from the workpiece surface and IR-heater.

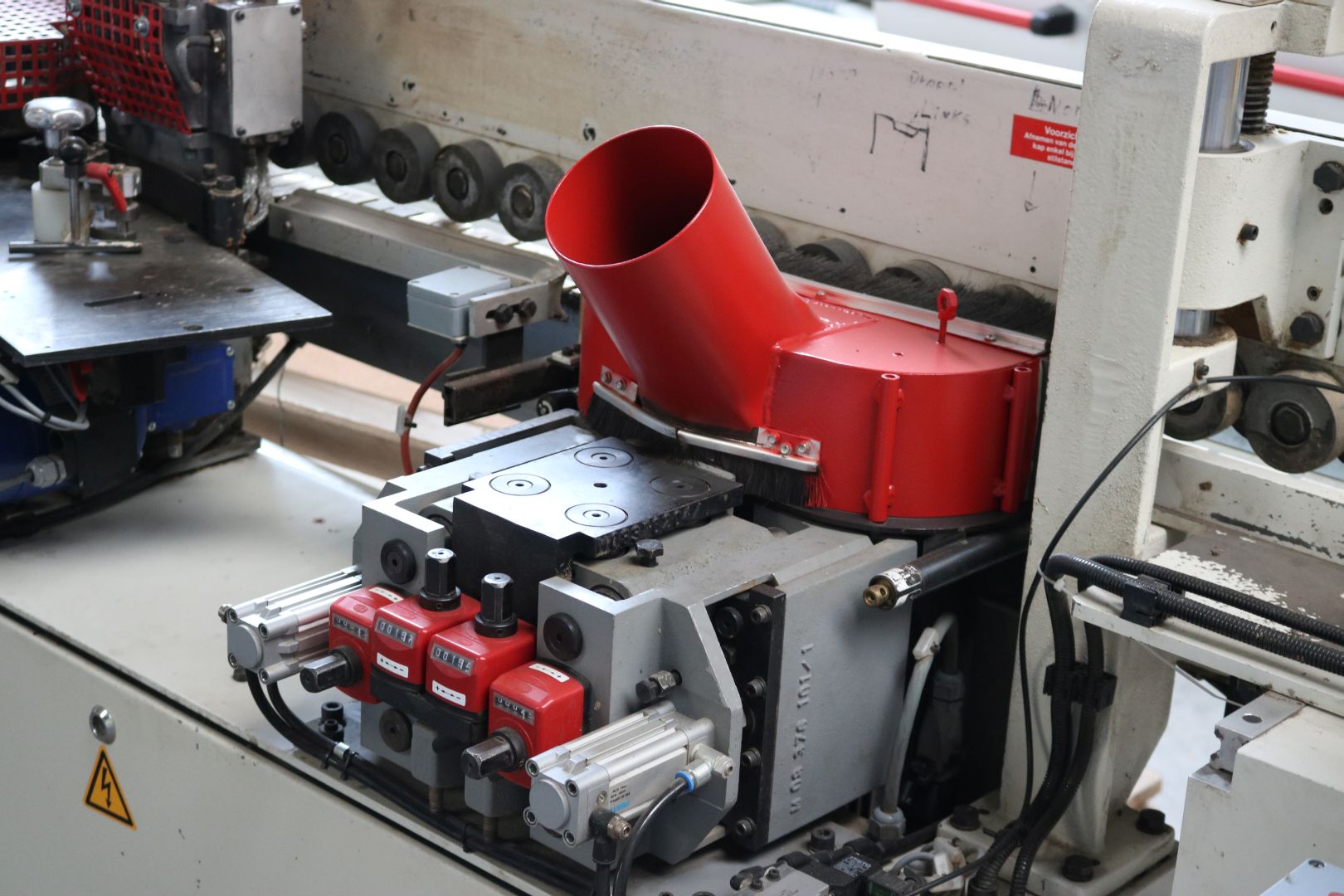

Gluing unit with closed oil-bath gear, temperature control with separate glue roller drive and 1 main pressure roller

5 re-pressure rollers with mech. digital display, pressure rollers single seitlich sprung and adjustbale on side.

Hot melt application 0,8 l compl. with heating cartridge and suplly plug max. edge height 50 mm

Single roller/strip magazine, feeding angle 8° for coil material up to 3 mm and strips up to 20 mm, end cutter pneumatic controlled, up to 3 mm edge thickness, max. edge cross sectional area 120 qmm, incl. restraint device for the coil ware, max. coilØ 860mm

End trimming unit

2 motors á 660 W, 400 V, 200 Hz., 12000 rpm, installed on top pressure for the end trimming of the frontal and rear edge or strip supernatant, for flush or chamfer cuts

Milling unit for flush milling from top and bottom, for 2 motors á 1850 W, 400 V, 200 Hz, 12000 rpm

max. approx. 3 degrees swivable (at workpiece thickness over 25 mm), with height tracing, without side tracing, motors ordered one above the other,

Multi function unit for fine milling or profile milling of the upper length edge as well as the frontal and rear edge,

with height and side tracing, pneumatical feed movement horizontal and verticale.

with 1 motor 660 W, 400 V, 200 Hz, 12000 rpm, with quick change,

Profile scraping unit

Chip collecting box for profile scraping unit

Self tracing scraping unit

Chamfer sanding/buffing unit

horizontal controllable, for cleaning the upper and lower flush milled edge materials or for the polishing of thick PP-/PVC-edges

Smoothing unit

to smooth the milled and scraped PVC/ABS-profile edge, for R=1,3-4 with 1 upper and 1 lower smoothing zone, with horizontal, pneumatical moving device, min. workpiece thickness 16 mm

Note:

The specifications and descriptions are a copy of the order confirmation at that time. Datas are for information and are not binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia