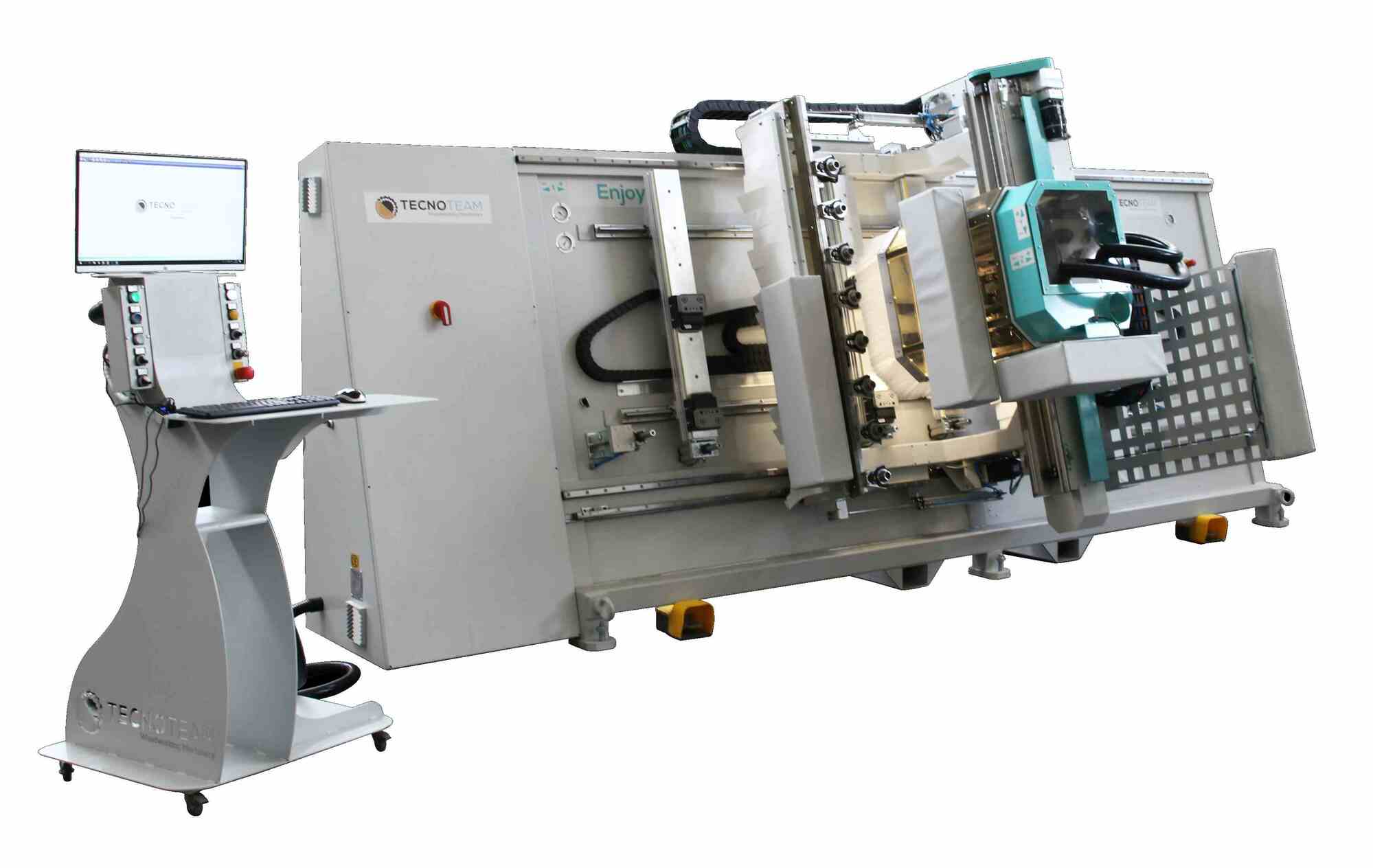

BrandTECNO TEAM

typeEnjoy Basic 3 Achsen

stateNew

stock number1110216

Think different - Think vertical

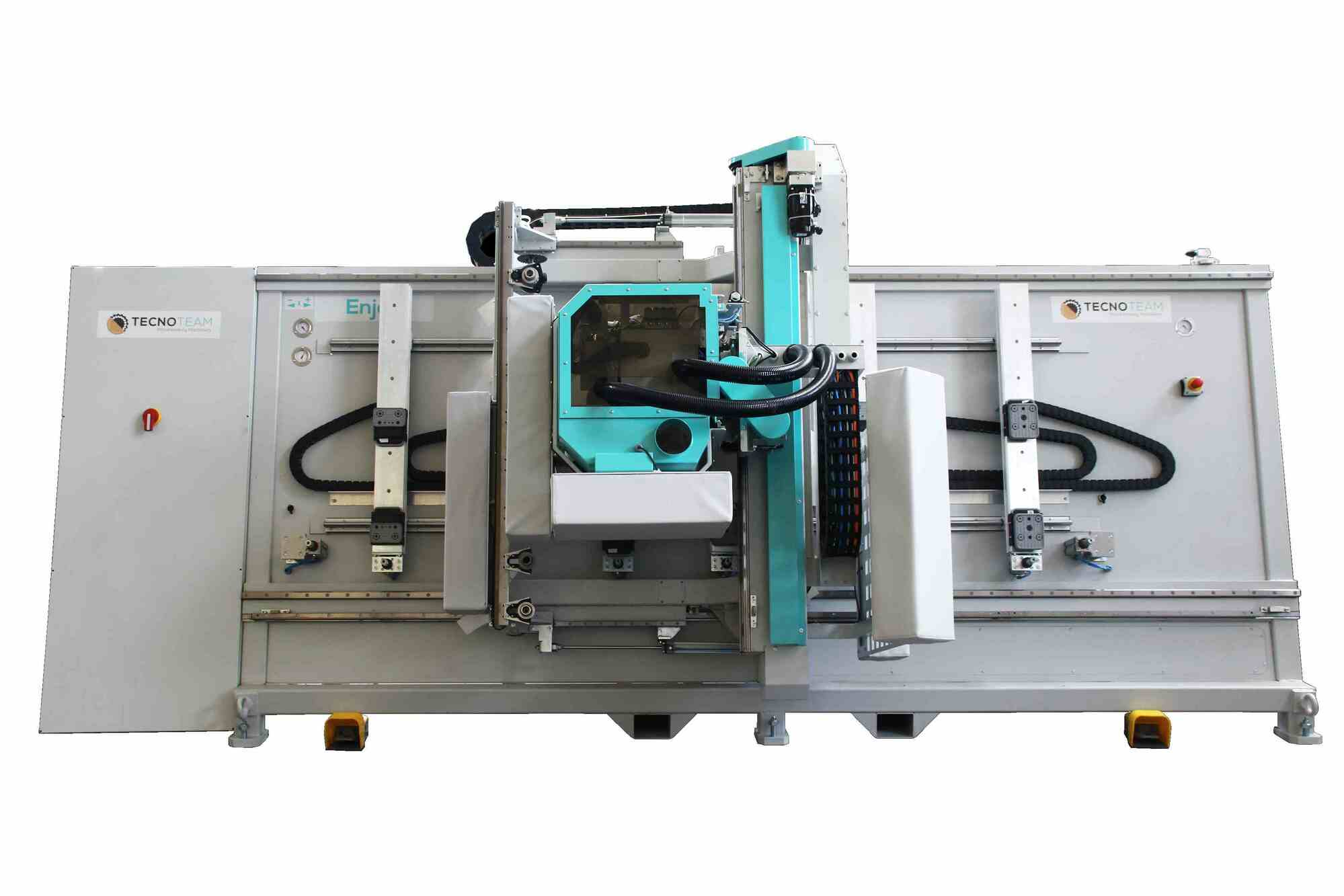

- Space saving, verticale contruction

- Workpieces are definetly fix on the machine

- Easy use with the TPA Software

- Available as 3- or 4-axis machine

Questions about this machine

CNC processing centre

Brand: TecnoTeam

Type: Enjoy Basic 3 Achsen

New machine

Save your space:

Standing upright means progress for human!

- With a vertical CNC machine you save a lot of space:

Wether for consuming material or a further machine, you have more space to use in your storage.

Easy machine use:

- TPA makes the use very easy, you find this software at several well-known machine brands

- You see the programmed processings on a virtual display, no matter which process: if circle, bow, linear millings or drillings,

- Create job lists in the CAM

- Forget the calculator, the machine calculates for you.

- For this software several genious tips and tricks are possible.

With realiability to success:

- Technoteam uses High-Quality components from well-established producers.

- We modify the machine exactly to your needs: If you process massive wood, you get a strong motor.

Workpieces are definitly fixed on the machine:

In autumn only leaves will fall and not your workpieces from the machine:

- The vacuum cups will definetly hold your panel, several Tecno Team customers can confirm this.

Technische Daten:

- Usable working length 3.000 mm

- Usable working width 1.100 mm

- Max. workpiece thickness at drillings 80 mm

- Max. workpiece thickness at millings 80 mm

- Working speed X- and Y-axis 24 m/min.

- Working speed Z-axis 12 m/min.

- Power spindle motor 5,5 / 9 kW

- Rotation speed of spindle with frequency changer 0 - 22.000 U/min.

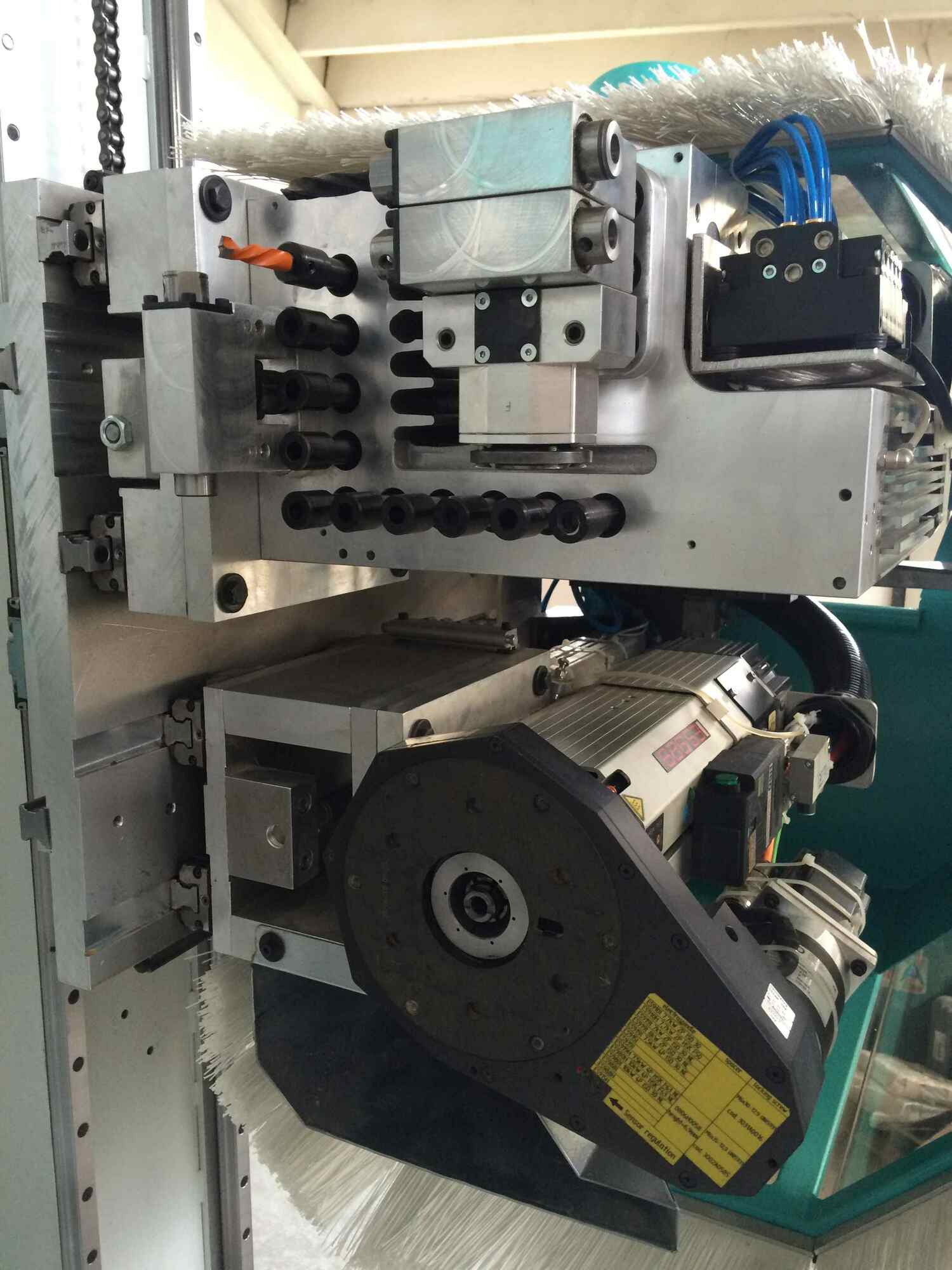

- Tool quick change system ISO 30 / HSK 63F

- Amount independant selectable verticale drilling spindles: 10 pieces

- Amount independant selectable horizontal drilling spindles: 6 pieces

- Spindle rotation speed 3.000 / 7.200 U/min.

- Vacuum pump 100 m³/h

- 8 Pieces squared vacuum cups 120 / 60 mm

- Prismatic linear guidances

- Max. installed electrical power 10 kW

- Min. - max. air pressure 7 - 10 bar

- Suction hood diameter 120 mm

- Packing dimensions 4.600 x 1.990 x 2.330 mm

- Net weight 2.500 Kg

Vacuum system (SCHMALZ ® System)

- 8 Pieces vacuum cups

- 4 Pieces aluminium consoles

- Vacuum pump "GEV" 100 m³/h, 400 V

Bearings / ball screw / linear guidances

- 4 Pieces bearings in X-axis

- 4 Pieces bearings in Y-axis

- Linear guidances H30 e H25

Axes / motors / drive cards

- Brushless drive motors / High Quality encoder

- Axes motors with gear and almost no room for backlash. between 5` and 3´

- High precise toothed rack with pinion in X

Ball screw in Y and Z almost with no room for backlash

Milling spindle HSD ES929 // 4 Pins

- Pneumatical opening ISO / HSK 63F

- Main spindle Power 5,5 / 9 kW

- Adjustable rotation speed main spindle 3.000 / 22.000 U/min.

- Air cooling for main spindle

- Inverter power 5,5 / 7,5 kW

Drilling head

- 10 verticale spindles

- 2 horizontal spindles from left hand side

- 2 horizontal spindles from right hand side

- 1 Spindle from top

- 1 Spindle from below

- 1 Saw blade X-axis; diameter 120 mm

Automatical tool changer (moving on X-axis)

- Automatical tool changer with 8 tool changing positions, moving in X-axis (tool change possible in each position)

Software und Hardware:

- PC Windows 10, latest version

- Lcd 24''

- Hardware PC HP

- Keyboard and optical mouse

- Network card for internet connection and remote servicing

- Software Cad-Cam Tpa Edi32 Bit or TPA CAD. Parametric Version Professional

- Software "Wood System Control" mit Listen zum Programme abarbeiten.

The machine is available in a further configuration as the "Enjoy Advanced 4 axis" machine.

Options:

- Speed 40 m/min.

- Angular gear (saw blade 0-360°)

- Angular gear with 2 exits (for milling 0-360°)

- USB Tpa office licence Dongel

- Automatical lubrication

- Vakuum cups

- Aluminium consoles (Schmalz®)

- 4 zero reference points

- Clamping stops

- LED setup support

- Bar Code laser

- "Lamello - Cabineo" Macro

- "Lamello - Clamex" Macro

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia