BrandTECNO TEAM

typeTecnoflex

stateNew

stock number1110217

- Space saving construction

- With 3,4 oder 5 axes

- Workpieces are definetly fix on the machine

- 1300mm Working width

- Workpiece thickness max. 150mm

Questions about this machine

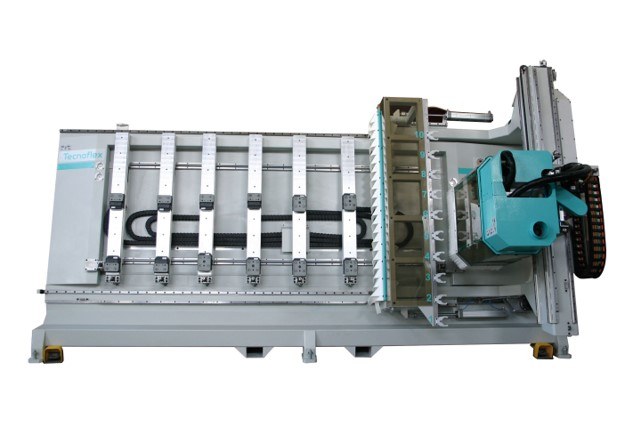

Vertical CNC processing centre with 3 axes

Brand: TecnoTeam

Type: Tecnoflex

New machine

The Tecno Flex is the space saving allrounder:

- This verticale CNC machine is available with 3, 4 or 5 axes

- On the Tecnoflex you have more working width and it allows thicker workpieces

- For process of wood, composites, PVC, plexiglas...

For your production only the best:

- Technoteam install High-Quality components from well-established producers.

- We modify the machine perfectly for your needs: If you process massive wood, you get a strong motor

Easy use with TPA Software:

- The CAD displays your programmed processings on a virtual display.

- You can mirror processes just with a mouse click.

- With variable programs your processings will be autom. modified f.e. when workpiece dimension changes.

- Create job lists with CAM

The construction as the base for a reliable process:

- Monolith machine frame with bridge structure and highest stiffness, standardized for precision.

- Bridge construction ("Y"-axis) with high stifness, made out of electro-welded steel.

- All movements are on high precise prismatic guidances with prestressed bearings, which are dust tight.

- Automatical lubrication

X-,Y-and Z-axis

- The movements of the axis "X" and "Y" are over pinions with toothed rack.

- The crosswise toothed racks are made out of hardened steel. The gears are high precise planet gears.

- The movement of the "Z"-axis is done via prestressed ball screw with precision bearings for a max. positioning precision.

- The computer controlled acceleration / deceleration togther with the high stiffness of the structure allows fast movements without vibrations.

Technical data:

- Total moving route: X = 3.600mm, Y = 1.903mm, Z = 363mm

- Max. workpiece size: X = 3.000mm, Y = 1.300mm, Z = 150mm

- Axes speeds: X = 25, Y = 25, Z = 12

- Power spindle motor 9 kW

- Spindle rotation speed with frequency changer 0 - 22.000 U/min.

- Tool quick change system ISO 30 / HSK 63F

- Amount independant selectable vertical driling spindles: 10 pieces

- Amount independant selectable horizontal drilling spindles: 6 pieces

- Rotation speeds drilling spindles 3.000 / 7.200 rpm.

- Vacuum pump 100 m³/h

- 12 Pieces squared vacuum cups 120 / 60 mm

- Prismatic linear guidances

- Static and dynamic grafic

- Max. installed electrical power 12 kW

- Min.- max. air pressure 6-10 bar

- Suction hood diameter 120 mm

- Packing dimensions 5.000 x 2.400 x 2.650 mm

- Net weight 2.900 kg

Equipment details:

Milling spindle 9 kW

- The milling spindle is equipped with blowing system for conus cleaning, which saves the precise tool hold.

- HSK 63F

- Rotation speeds 0 - 22.000 U/min.

- Max. diameter 180 mm

Drilling head

- 10 vertical spindles

- 2 horizontal spindles from left hand side

- 2 horizontal spindles from right hand side

- 1 Spindle from top

- 1 Spindle from bottom

- 1 Saw blade X-axis; diameter 120 mm

Automatical tool changer (moving on the X-axis)

- Automatical tool changer with 10 tool changing places, moving on the X-axis (tool change possible in each position)

Your workpieces are definetly fixed by the vacuum:

- 12 Pieces vacuum Sauger

- 6 Pieces aluminium consoles

- Vacuum pump "GEV" 100m³/h, 400 V

Software und Hardware

- PC Windows 10, latest version

- Lcd 24"

- Hardware PC HP

- Keyboard and optical mouse

- Network card for internet connection and remote service

- Software Cad-Cam TPA CAD. Parametric Version Professional

- Software "Wood System Control" with lists to work the programms.

Options

- Speed 40 m/min.

- 4th axis / C-axis

- 5 Axis milling spindle; surcharge to the 3 axes machine

- Angular gear (saw blade 0 - 360°)

- Angular gear with 2 exits (for milling 0 - 360°)

- USB Tpa office licence dongel

- Vacuum cups

- Aluminium consoles (SCHMALZ ®)

- 4 zero reference points

- Clamping stops

- LED setup support

- Bar Code laser

- "Lamello - Cabineo" Macro

- "Lamello - Clamex" Macro

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia