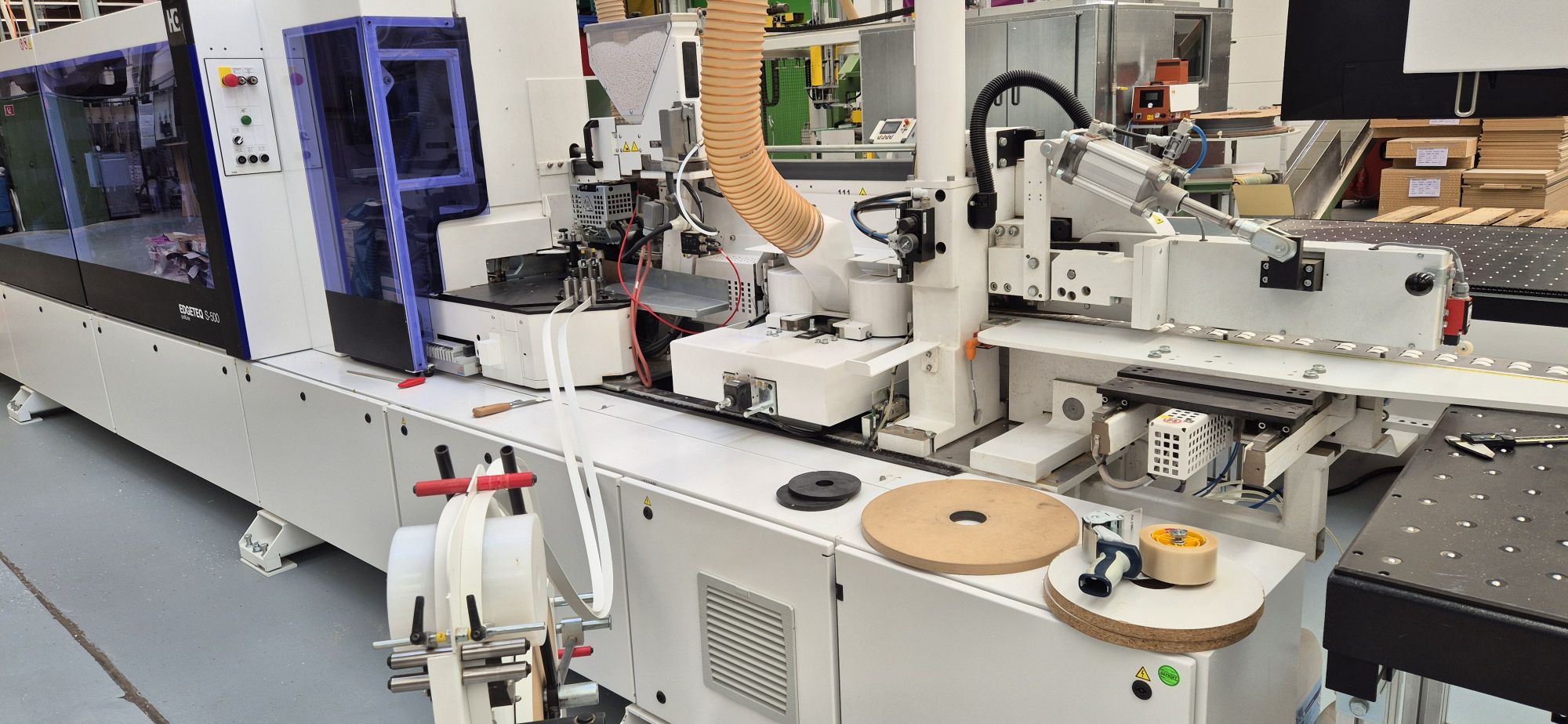

BrandHOMAG

typeEDGETEC S-500

stateUsed

stock number0401803

year2021

Year of manufacture: 2021

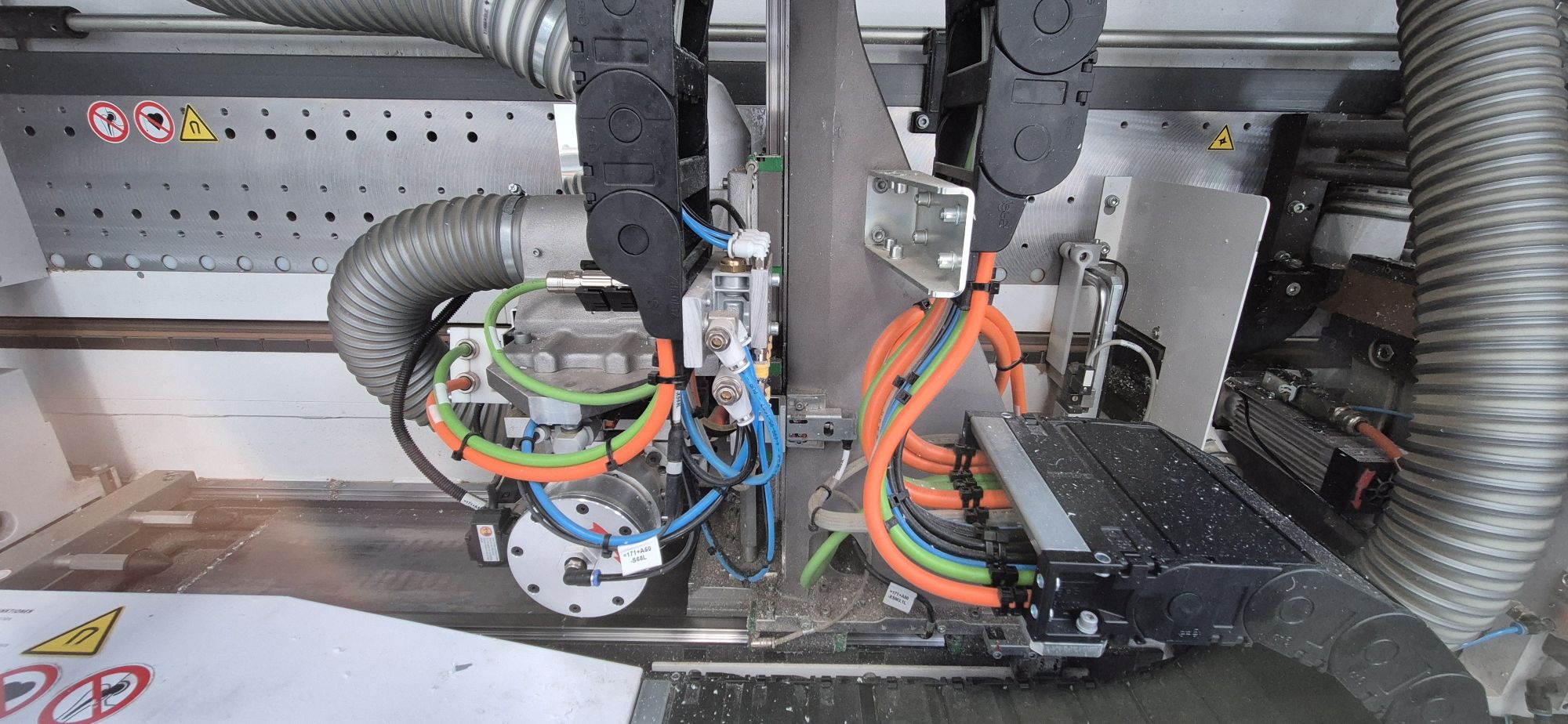

Joint trimming unit with 2 motors, each 3 kW

Gluing unit with EVA melting unit (6 liters), QA65P application unit for EVA, polyolefin, and PUR

Airtec activation unit

Cutting unit PK 25

Pre-trimming unit with 2 motors

Trimming unit PF 21

Profile trimming unit FK30/V20

Trimming unit FK30/FK31

Multi-scraper MN21

Glue joint scraper

Buffing unit FP 10

1 grooving unit

Workpiece return

Questions about this machine

edge banding machine with recirculation

Brand: Homag

type: EDGETEC S-500 / TFU 140

Year of construction: 2021

technical data

Fixed fence set left

Workpiece thickness 8 - 60 mm, feed adjustable 16 - 25 m/min.

Motor-driven top pressure belt

Release agent spraying unit

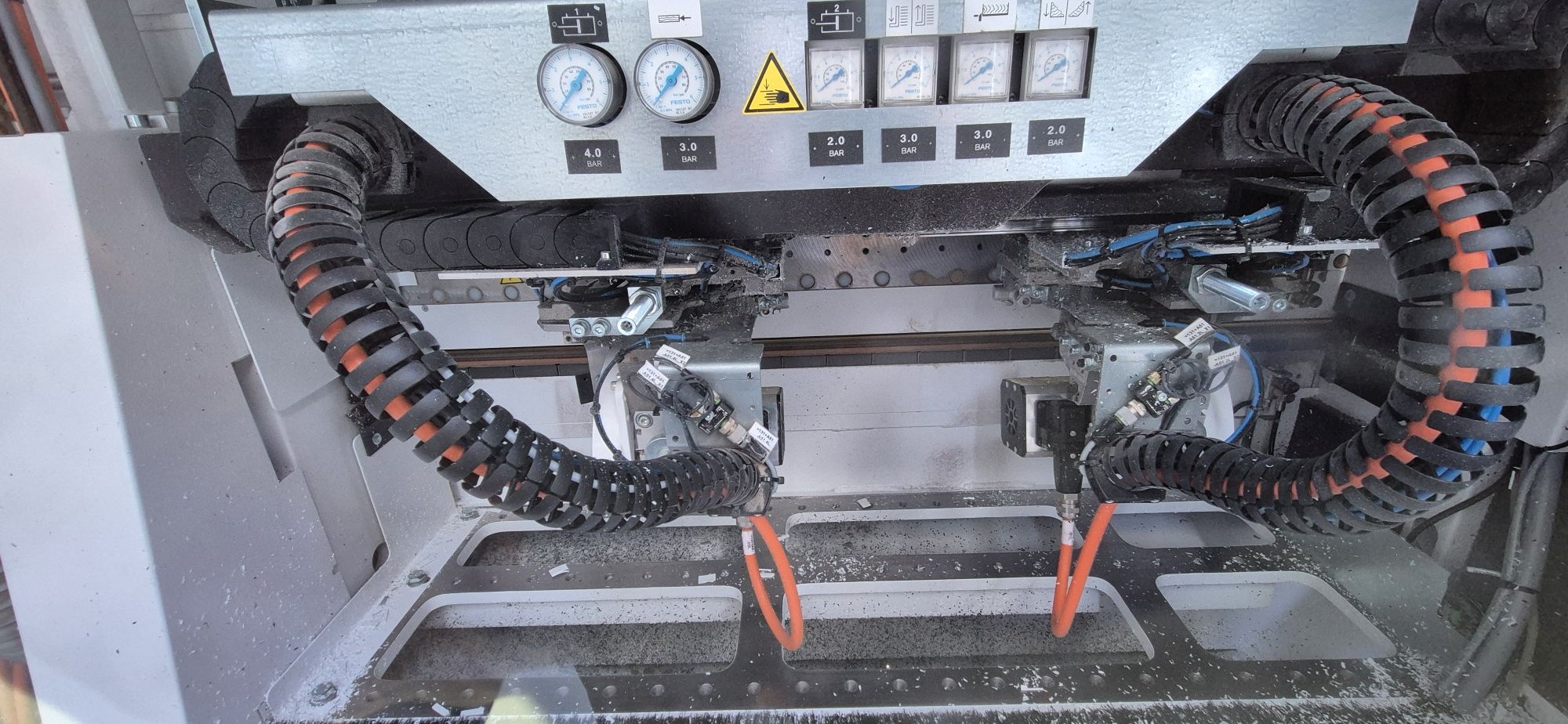

Joining unit with 2 motors 3 KW each

Gluing unit with EVA melting unit 6 litres, application unit QA65P for EVA, polyolefin, PUR

Airtec activation unit for edgebands with functional layer

Automatic roll change with 2 edge feeders

Coolant / lubricant spraying unit

PK 25 snipping unit, with 2 motors 0.8 KW each, pneumatically swivelling for chamfer snipping

Pre-milling unit with 2 motors 1.5 KW each, with 3-fold vertical tracing, pneumatic adjustment to

2 positions

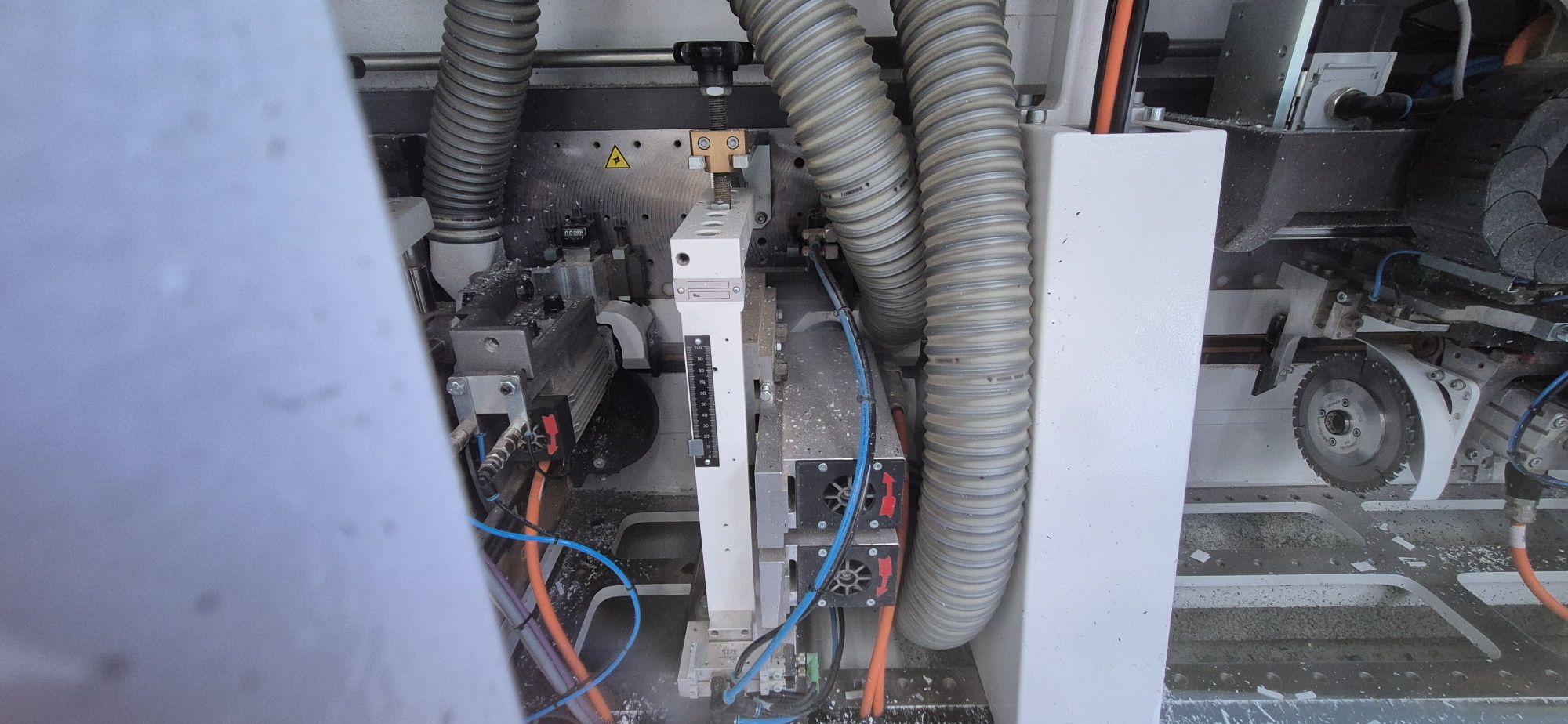

Trimming unit PF 21 FLEXTRIM, with 3-fold tracing

Moulding unit FK30/V20, path-controlled servo drives

Moulding unit FK30/FK31 FLEXTRIM for 2 tools, with 1 motor 0.7 KW

Automatic multi-blade MN21, with 3-fold tracing

Cleaning agent sprayer

Glue joint scraper

Buffing unit FP 10

1 grooving unit, horizontal shaft

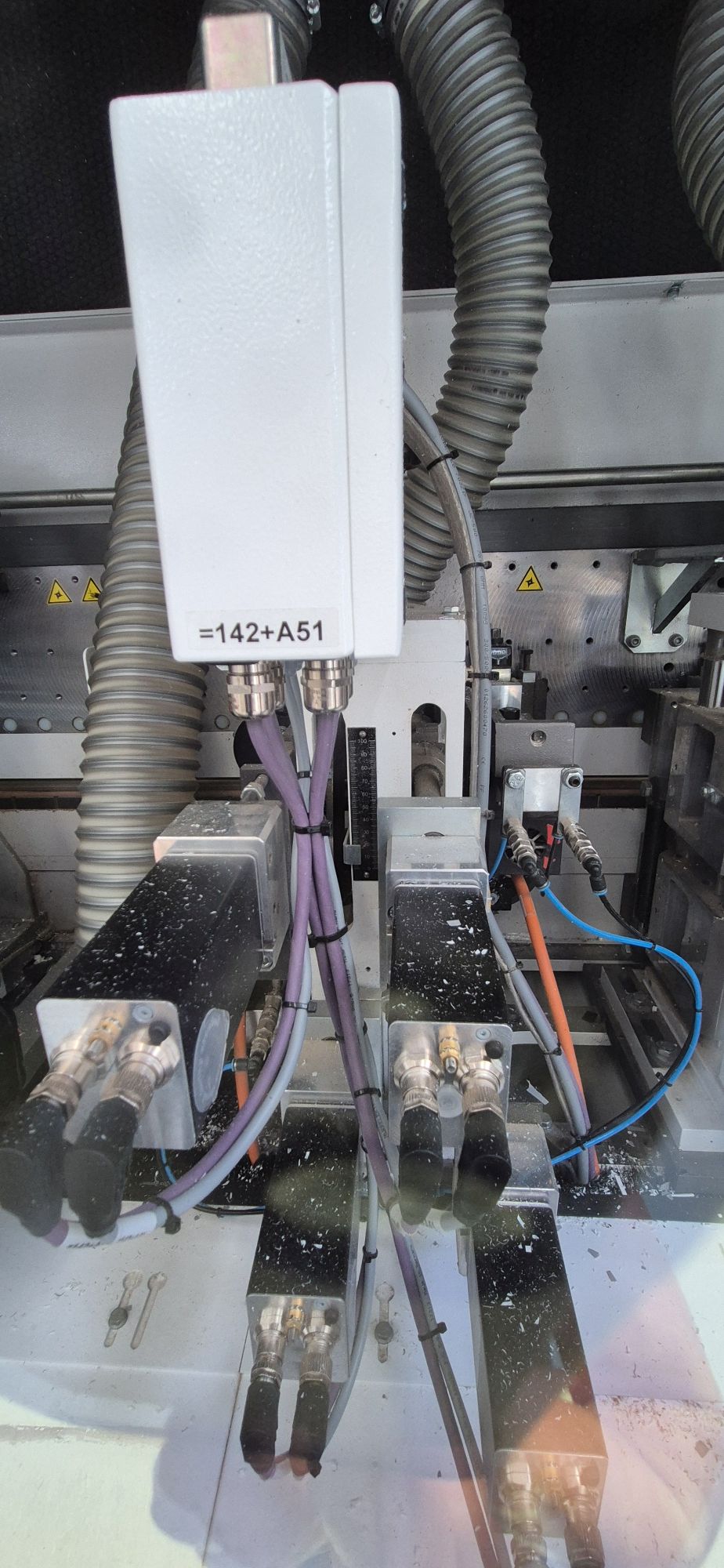

POWERCONTROL PC 23 control unit, with set-up in the gap

Workpiece return LOOPTEQ O-300

With lowerable air cushion table at the machine outlet

Conveyor belt with lateral, lowerable roller bar

At the outfeed of the return conveyor section 1 air cushion table with lifting device

Note:

The technical data and descriptions are transcribed from the original order confirmation. The information is for reference only and is not legally binding.

Contact person

Eugen Pries

Sales East Europe & Asia

Ralf Teubner

Sales Swiss & International

Richard Brakweh

Sales Belgium, Netherlands, Luxembourg & Scandinavia